Self-locking patch board

A plug-in board and self-locking technology, applied to electrical components, coupling devices, circuits, etc., can solve the problems of falling off, inconvenient use, and difficulty in replacing the plug-in board, and achieve the effects of easy promotion, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will be described in conjunction with the accompanying drawings and specific embodiments.

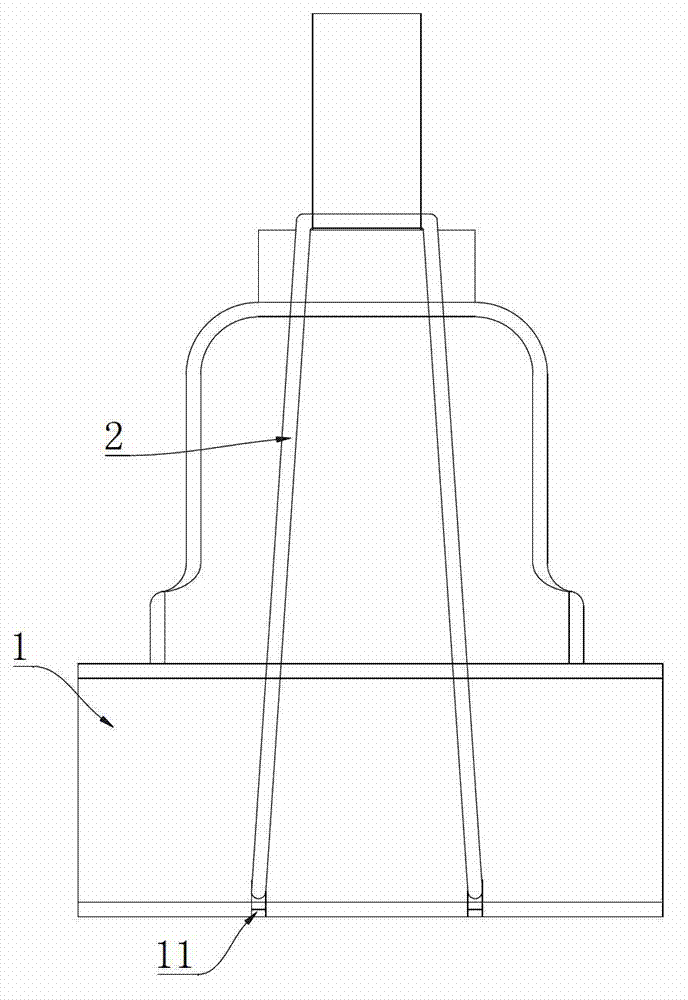

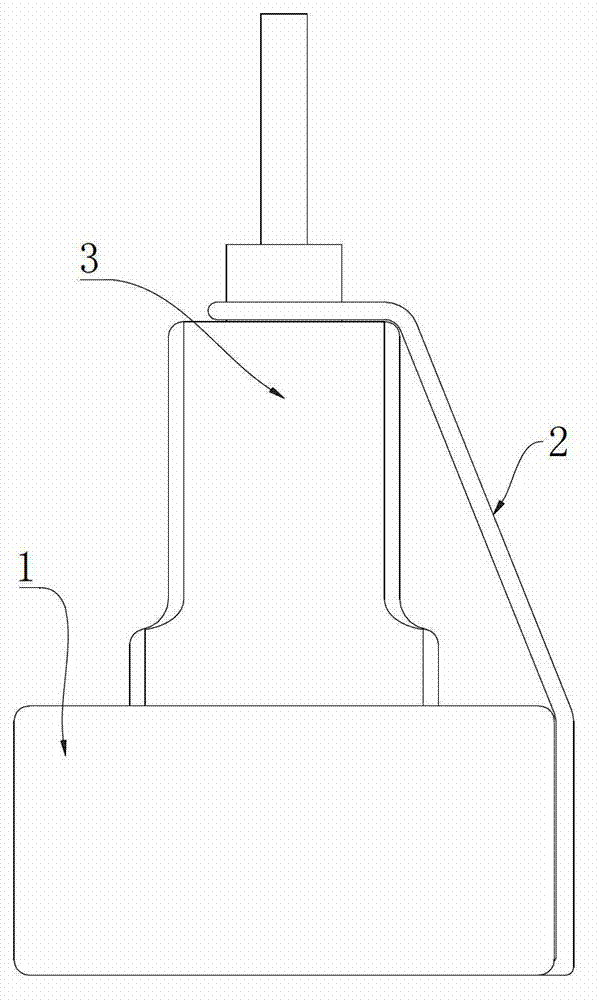

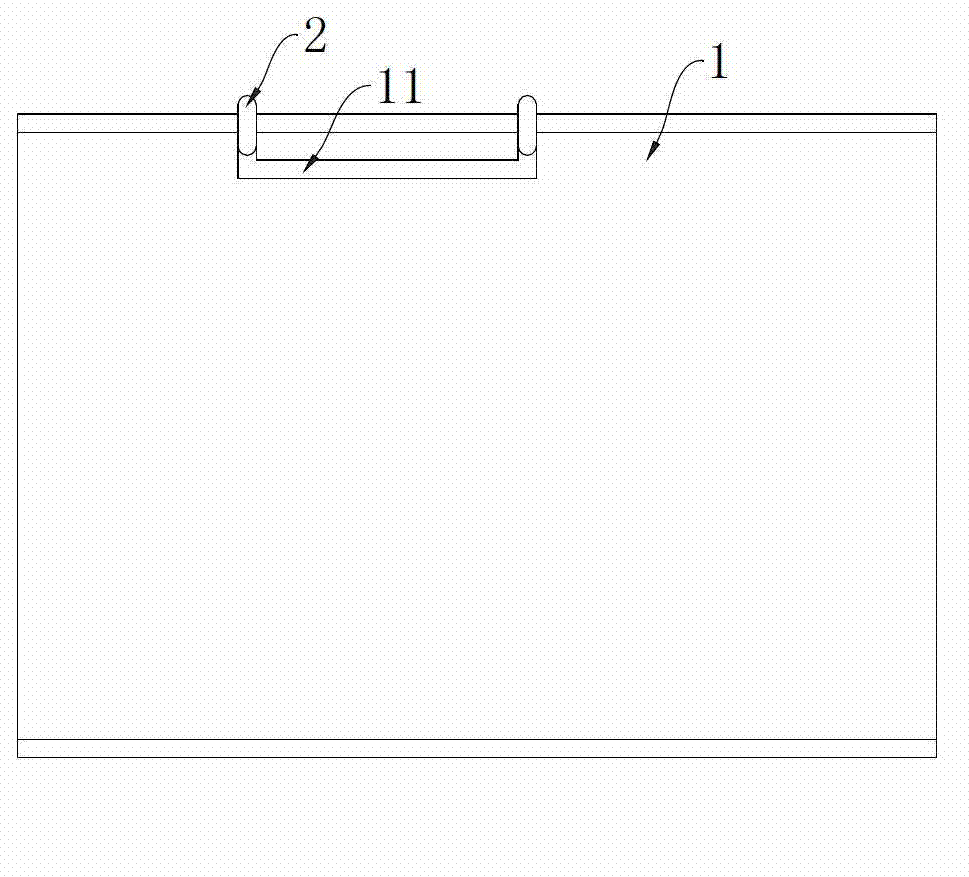

[0013] see Figure 1 to Figure 3 . The self-locking power strip described in this embodiment includes a socket head, a power cord and a power strip body 1 . The bottom side of the plug-in body 1 is provided with a suspension groove 11, and the suspension groove 11 has the same symmetrical plane as the nearest wire insertion hole group. The elastic coil 2 is suspended on the suspension groove 11 . Elastic coil 2 selects rubber band for use in the present embodiment. During use, first take off the rubber ring, after the electric plug 3 is entangled with the rubber ring, the rubber ring is hung on the suspension groove 11 again. The suspended rubber ring tightly pulls the socket body 1 and the electric plug 3, so that the socket body 1 and the electric plug 3 are not easy to fall off under the action of external force.

[0014] The above are only preferred impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com