Branched duct construct, and uniaxial eccentric screw pump system

A structure and screw pump technology, applied to parts of pumping devices for elastic fluids, rotary piston pumps, pumps, etc., can solve the problems of flow path design restrictions, branch flow path difficulties, discharge pressure, and discharge volume Equalization is difficult and other problems, to achieve the effect of simplifying the structure of the flow path and reducing the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

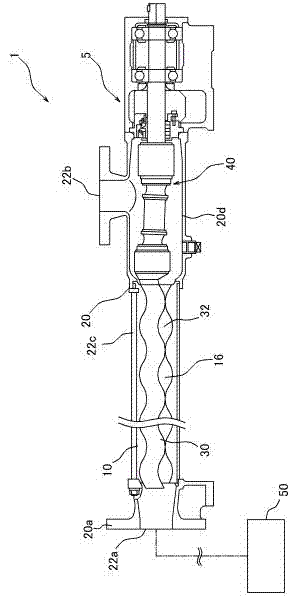

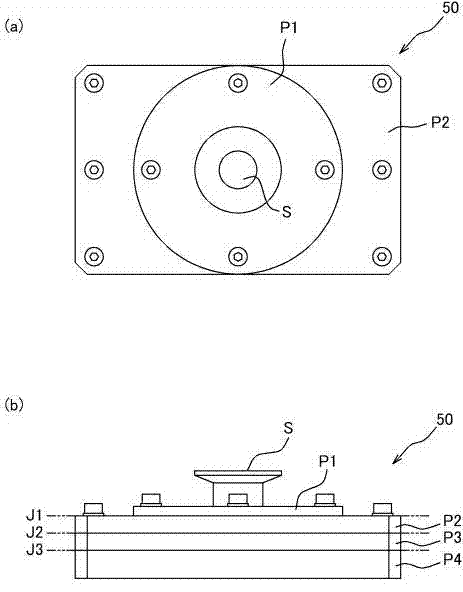

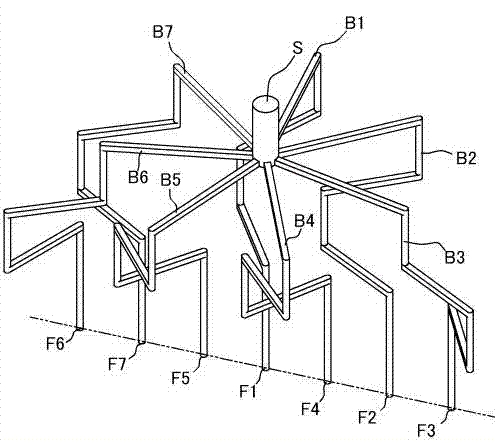

[0035] Next, the uniaxial eccentric screw pump system 1 (hereinafter, simply referred to as "pump system 1") and the branch flow path structure 50 of the present invention will be described in detail with reference to the drawings. The pump system 1 is composed of a single-axis eccentric screw pump 5 and a branch flow path structure 50 . The pump system 1 of the present embodiment is characterized by the branch flow path structure 50 , and before describing this, the structure of the uniaxial eccentric screw pump 5 will be briefly described.

[0036] (About one-axis eccentric screw pump5)

[0037] The one-axis eccentric screw pump 5 is a so-called drum pump, and is configured such that a stator 10 , a rotor 30 , a power transmission mechanism 40 , and the like are housed inside a casing 20 . Such as figure 2 As shown, the stator 10 is a component assembled into the one-axis eccentric screw pump 5, and has an elliptical cross-sectional shape, and is a cylindrical body ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com