Ceramic edge strip for foamed ceramic production and preparation method thereof

A foamed ceramic and fence technology, applied in the field of ceramic fence and its preparation, can solve the problems of short service life, increase ineffective energy consumption of kilns, increase energy consumption, etc., to reduce ineffective energy consumption, facilitate popularization, application, and molding easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

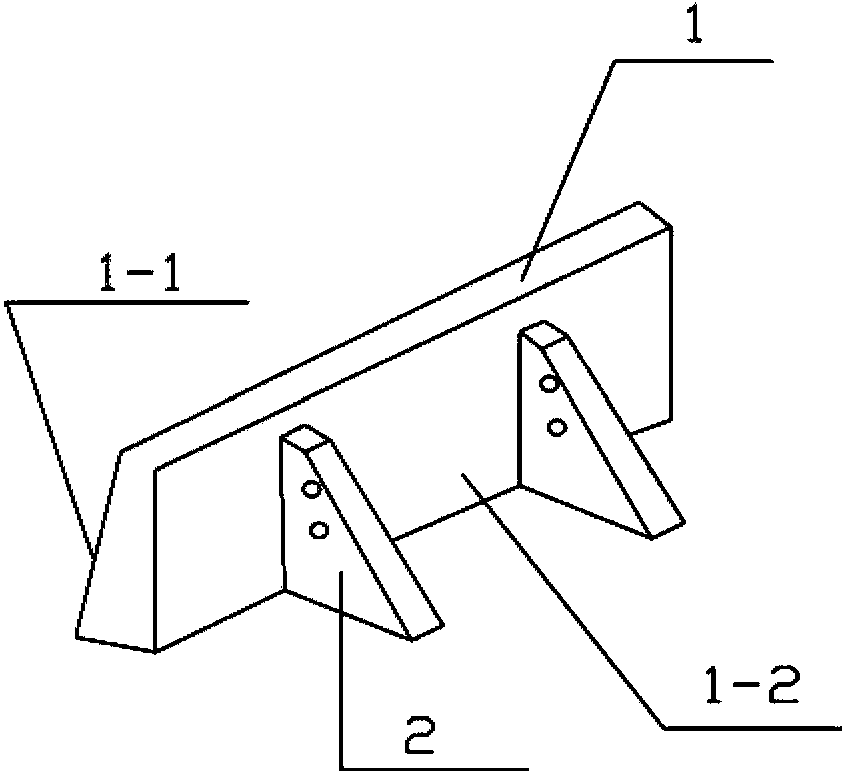

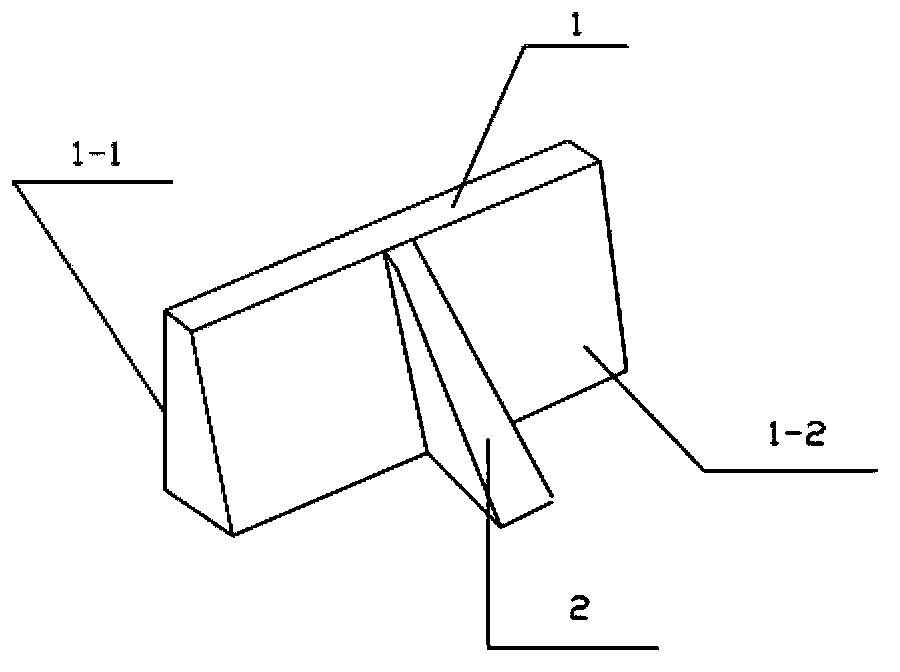

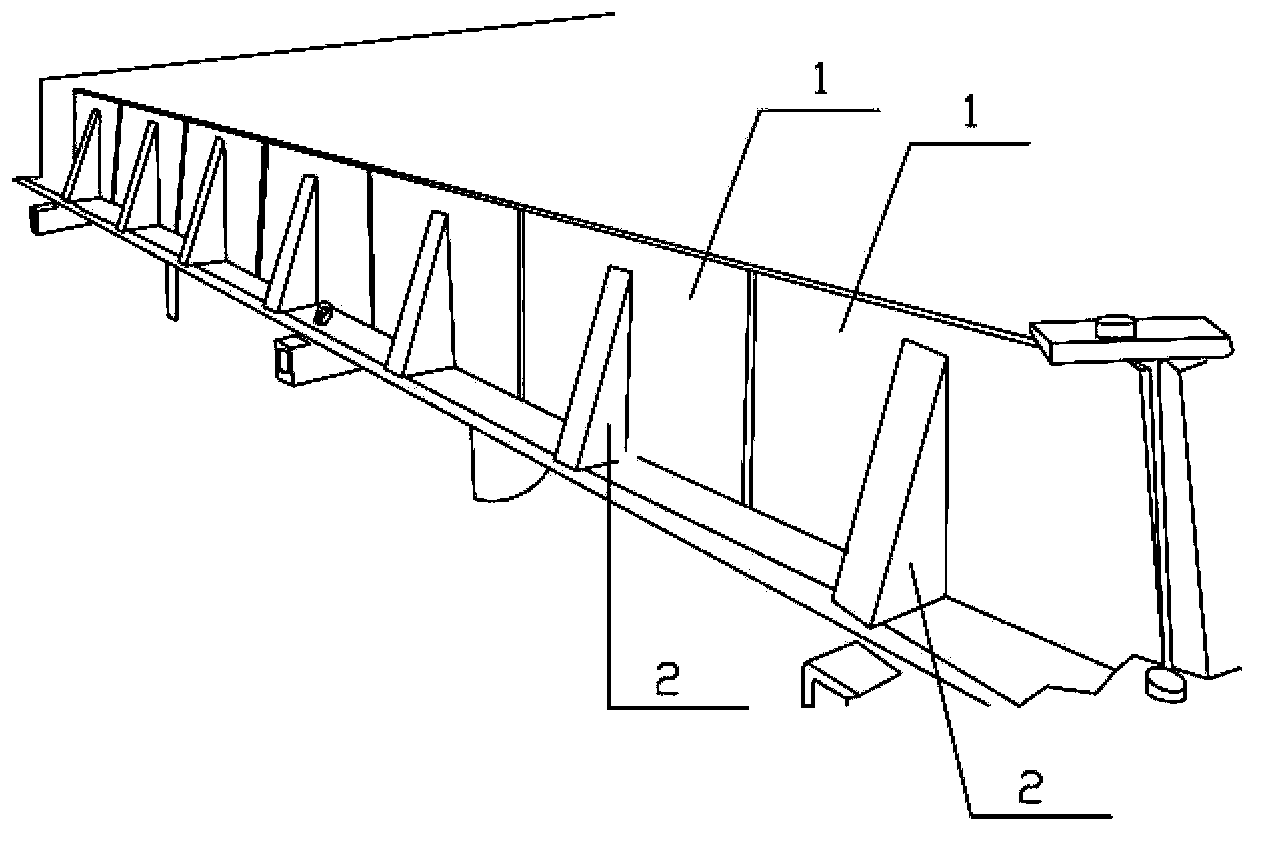

Method used

Image

Examples

Embodiment 1

[0027] A ceramic fence for the production of foamed ceramics, which is made of the following raw materials: 50% bauxite aggregate, 15% corundum aggregate, and 35% super-grade bauxite refractory fine powder. Aluminum phosphate solution of 14.5% of the weight of the ingredients, calcium aluminate cement accounting for 1.5% of the weight of the base ingredients, silica fume and alumina mixed micropowder accounting for 6.0% of the weight of the base ingredients, wherein,

[0028] The weight ratio of silica fume to alumina micropowder in silica fume and alumina mixed micropowder is 3.5:2.5; this content can not only improve the fluidity of the batch material, but also ensure the high temperature creep resistance of the product;

[0029] The mass concentration of aluminum phosphate solution is 45%;

[0030] Among them, the refractory aggregate is made by mixing bauxite aggregate with a weight ratio of 50% and corundum aggregate with a weight ratio of 15%. The grading of the refracto...

Embodiment 2

[0035] Example 2: It is basically the same as Example 1, the difference is:

[0036] A ceramic fence for the production of foamed ceramics, which is made of the following raw materials: 75% bauxite refractory aggregate, 25% super-grade bauxite refractory fine powder to form a base batch, accounting for 12.5% of the base batch weight Phosphoric acid Aluminum solution, calcium aluminate cement accounting for 2.0% of the base batching weight, silica fume and alumina mixed micropowder accounting for 6.80% of the base batching weight, this batching material has a larger bulk density, higher high temperature strength, and the green body is hardened and released from the mold faster. in,

[0037] The refractory aggregate is bauxite, and the grading of the refractory aggregate is: coarse: medium: fine = 5.5: 2: 2.5, and the maximum particle size is not greater than 6mm.

[0038] The special-grade bauxite refractory fine powder requires 90% of the particle diameter to be less tha...

Embodiment 3

[0043]A ceramic fence for the production of foamed ceramics, which is made of the following raw materials: 60% bauxite refractory aggregate, 10% cordierite aggregate and 30% first-grade bauxite refractory powder Ingredients, aluminum phosphate solution accounting for 12.5% of the weight of the base ingredients, calcium aluminate cement accounting for 2.0% of the weight of the base ingredients, silica fume and alumina mixed micropowder accounting for 6.60% of the weight of the base ingredients, this batch has a greater bulk density, Higher high temperature strength, green body hardening and demoulding faster. in,

[0044] The refractory aggregate is composed of 60% bauxite refractory aggregate and 10% cordierite aggregate, the maximum particle size is not greater than the maximum particle size is not greater than 6mm, coarse: medium: fine = 5.5: 2: 2.5. The advantages of this batch material are low cost, simple ingredients, fast green solidification, and meet the production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com