Patents

Literature

37results about How to "Reduce ineffective energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

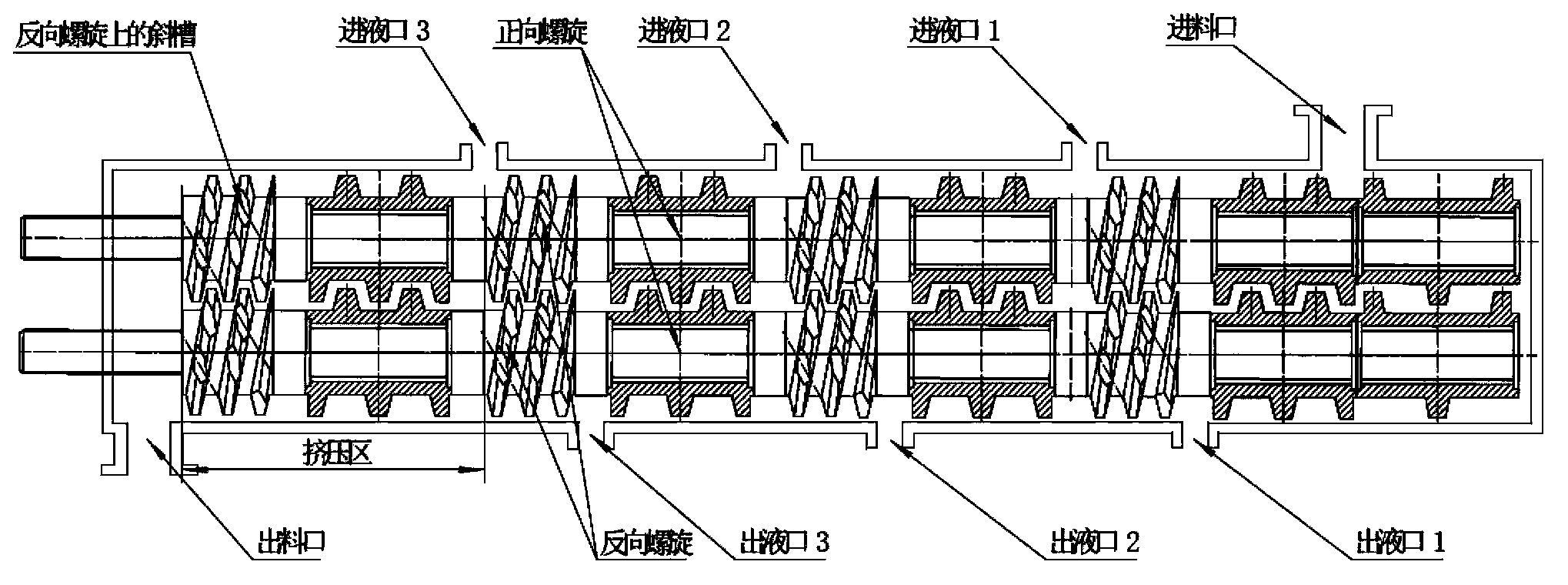

Method for pretreating cellulosic biomass

InactiveCN103790056ASimple processing methodIncrease contact areaEnergy inputFermentationMechanical crushingLignocellulosic biomass

The invention relates to relates to a method for pretreating cellulosic biomass, which comprises the following steps: before or after the cellulosic biomass is mechanically crushed, or when the cellulosic biomass is mechanically crushed, the cellulosic biomass is contacted with a chemical drug capable of degrading the cellulosic biomass, and the heat generated due to mechanical crushing is used for increasing the temperature of a mixture of the cellulosic biomass and the chemical drug.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

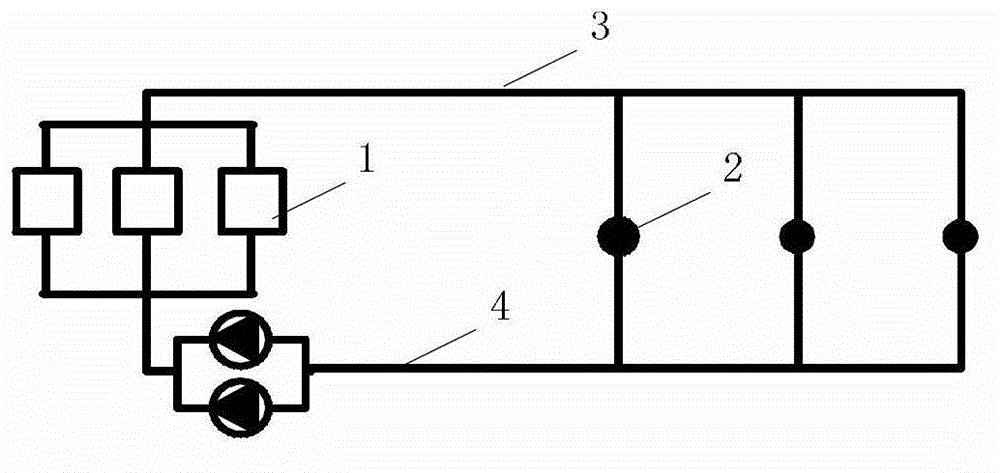

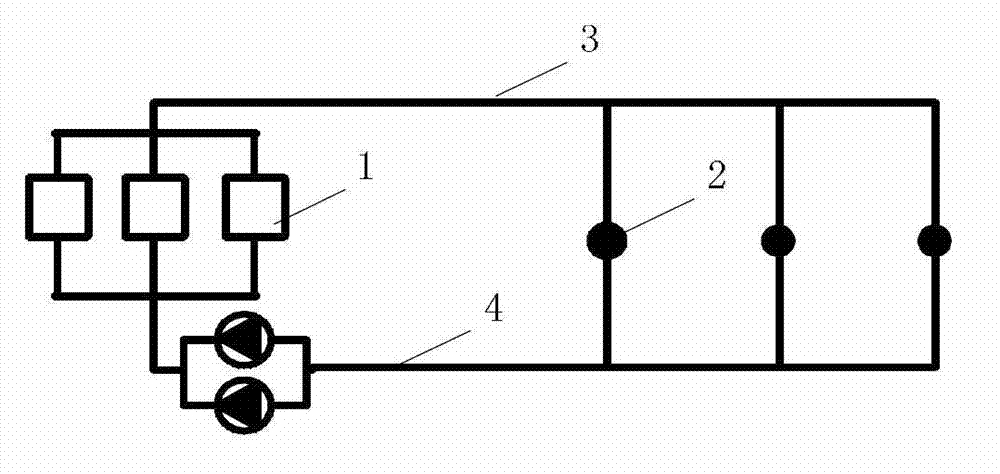

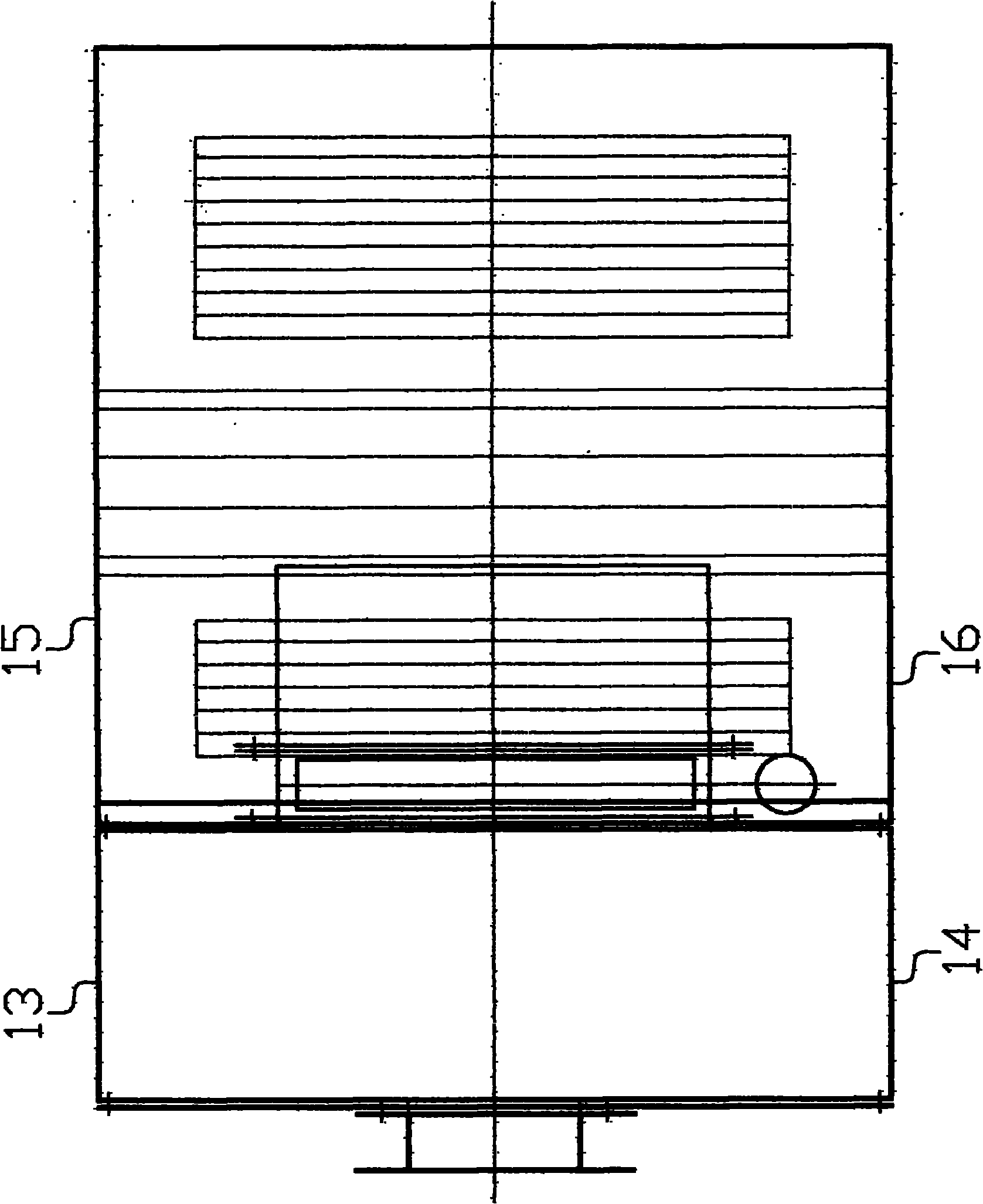

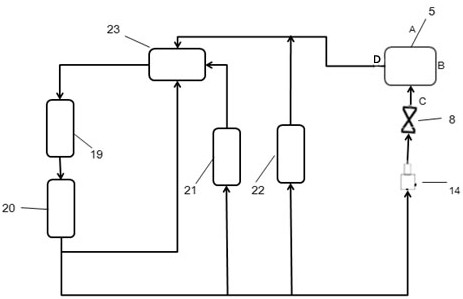

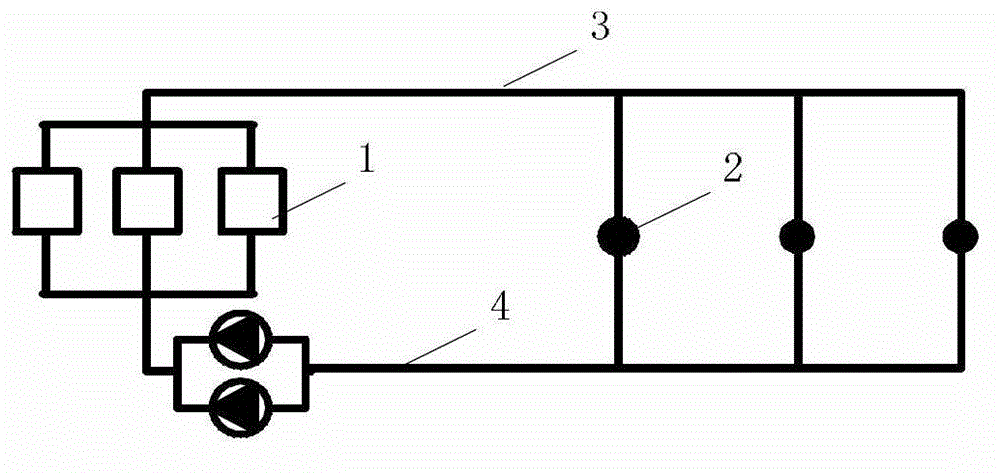

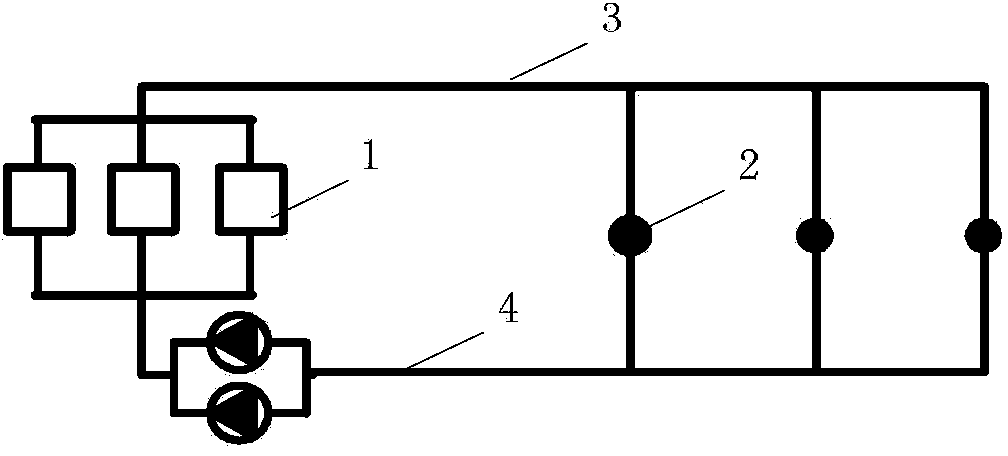

Multistage distributed water pump heat supply system and design method thereof

InactiveCN102944034AExcellent hydraulic stabilityReduce transportation energy consumptionLighting and heating apparatusHot-water central heatingConnection typeFrequency conversion

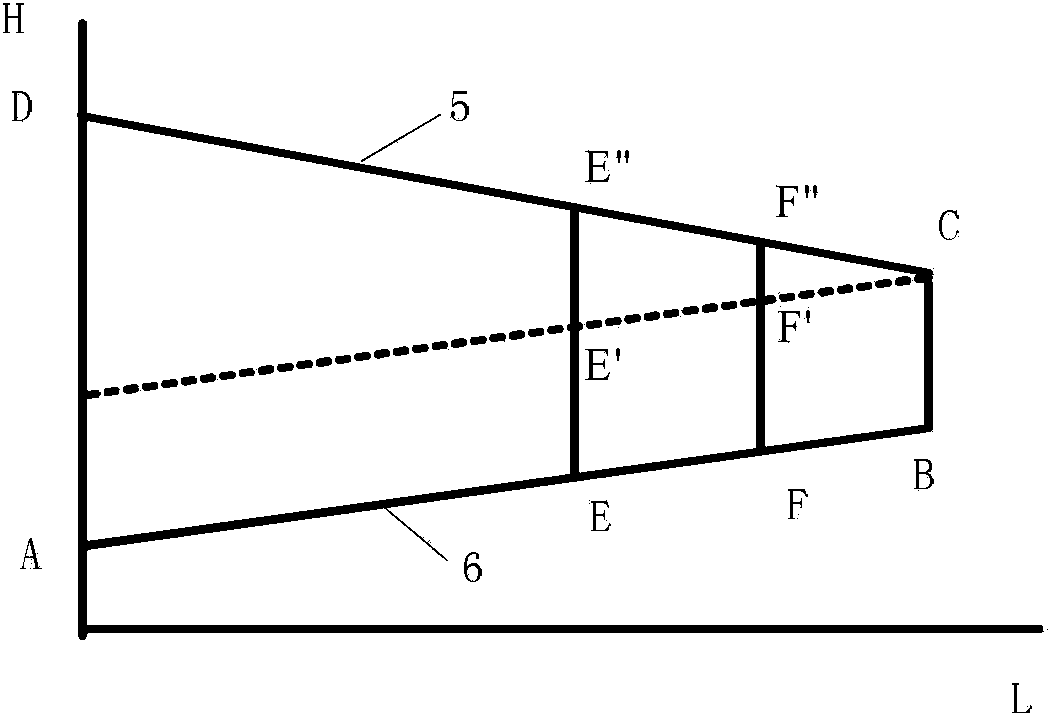

A multistage distributed water pump heat supply system and a design method thereof relate to a heat supply system and the design method thereof. The system and the method aim at resolving the problem that a traditional direct connection type central heating system is large in ineffective energy consumption, hydraulic power work conditions are mutually coupled, hydraulic power work conditions of a distributed frequency conversion water pump system are coupled and cannot meet the requirement for system extension or load change, balance of hydraulic power of heat users before zero-pressure different point is damaged, and the existing heat supply system adopting a voltage sharing tank is large in ineffective energy consumption and large in voltage sharing tank diameter. The multistage distributed water pump heat supply system comprises a heat source, a heat source position circulation water pump unit, a water supply pipe, a water return pipe and a multistage distribution station. Each-stage distribution station comprises a decoupling tube, a classification pressurization pump and at least one secondary net loop. Each secondary net loop is composed of a heat user pressurization pump and at least one heat user. Decoupling pipes of the multi-stage distribution station are arranged in parallel. The multistage distributed water pump heat supply system is used for centralized heat supply.

Owner:HARBIN INST OF TECH +1

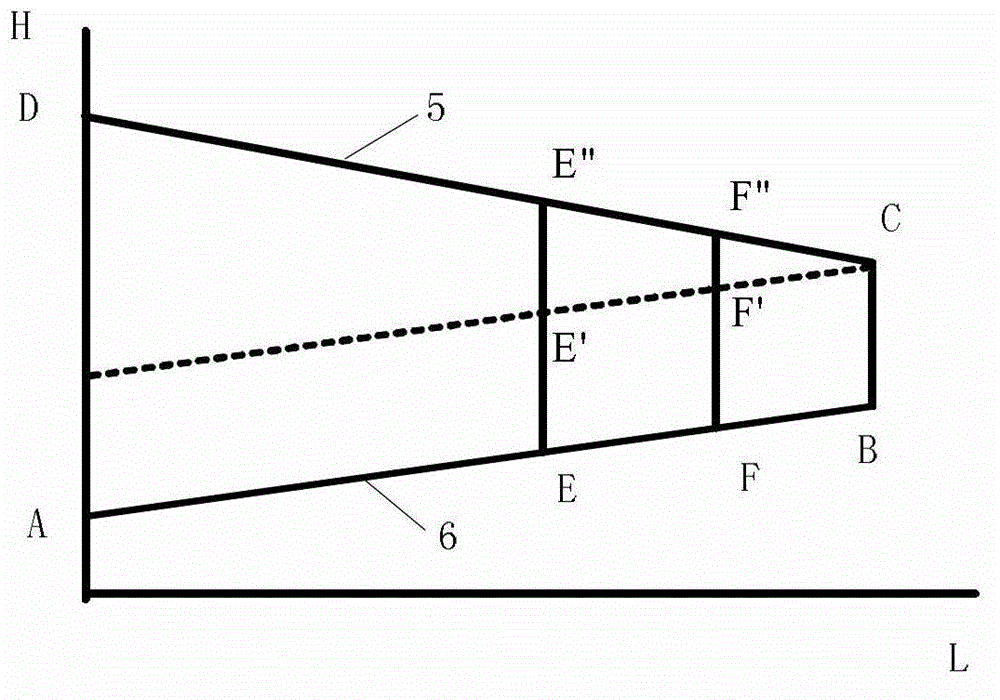

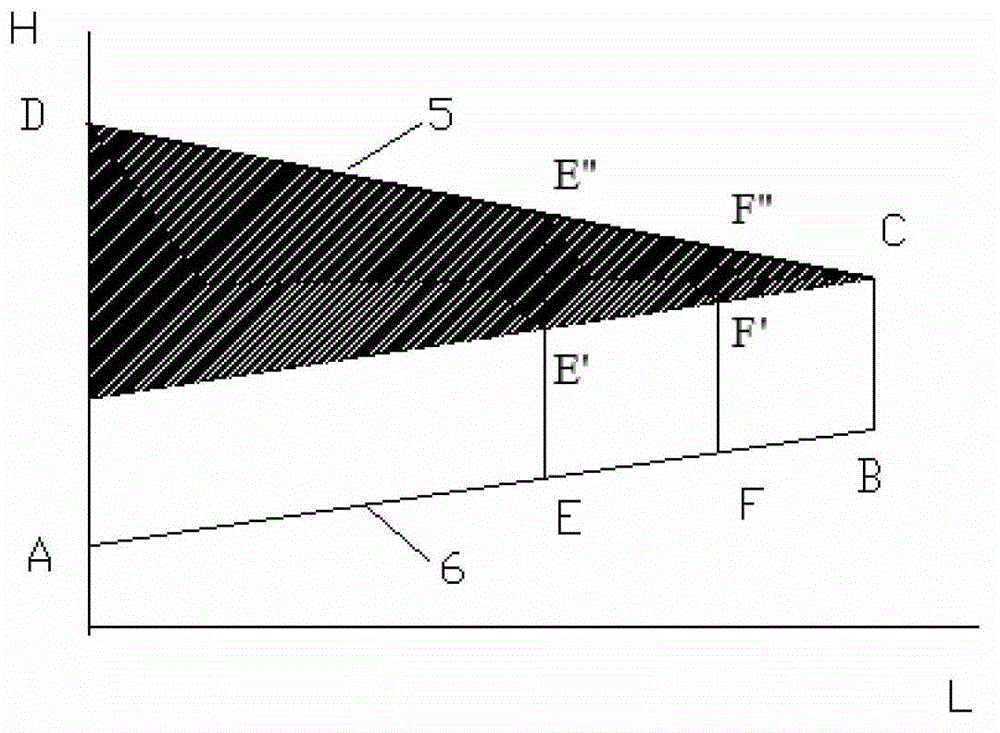

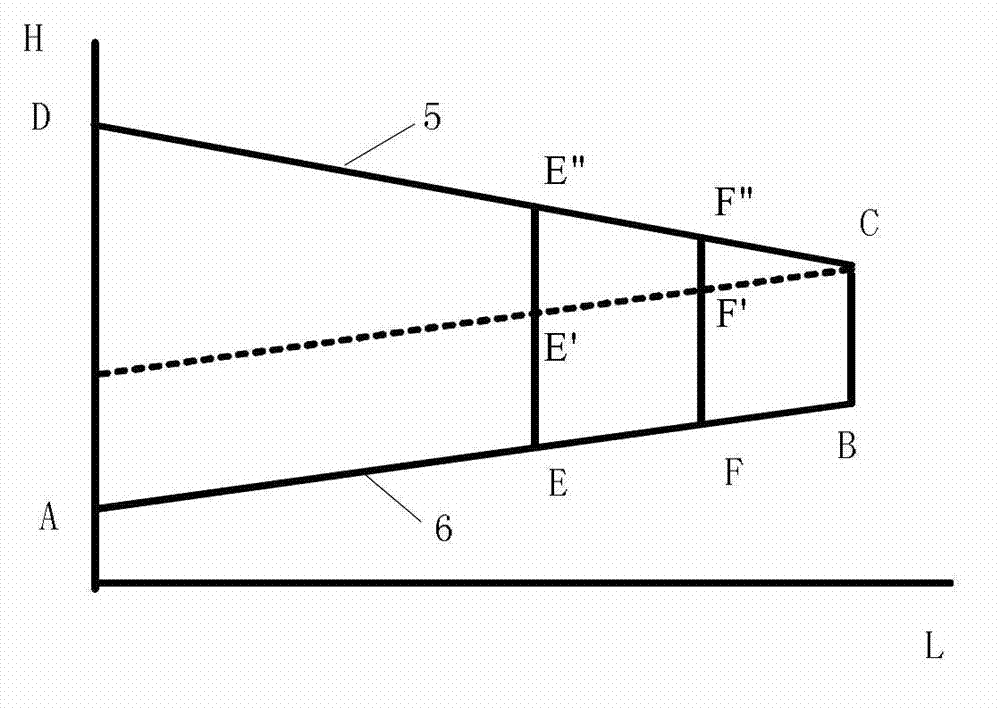

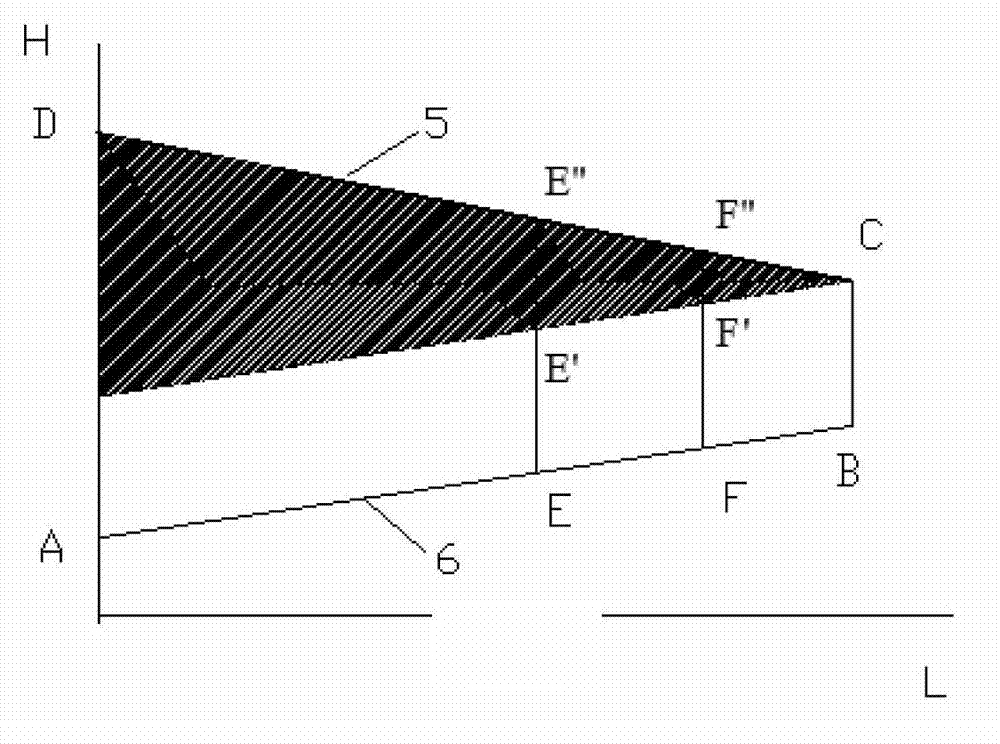

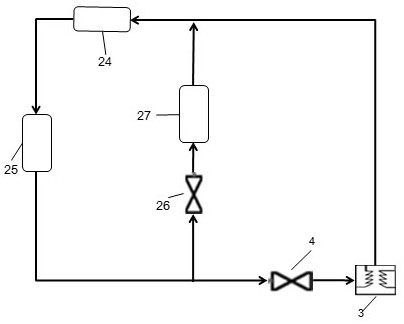

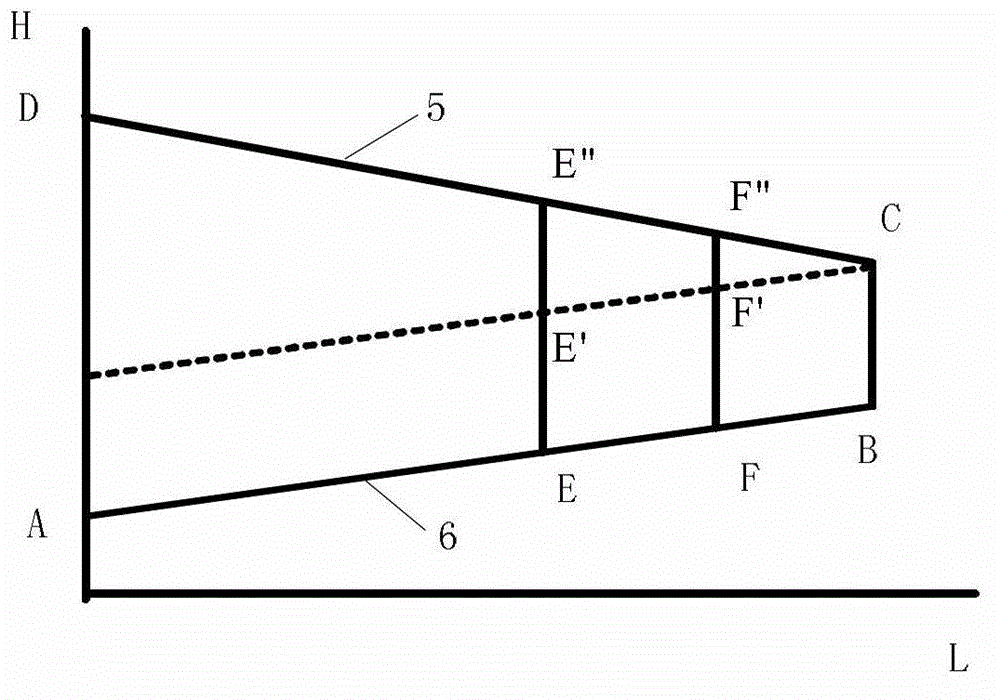

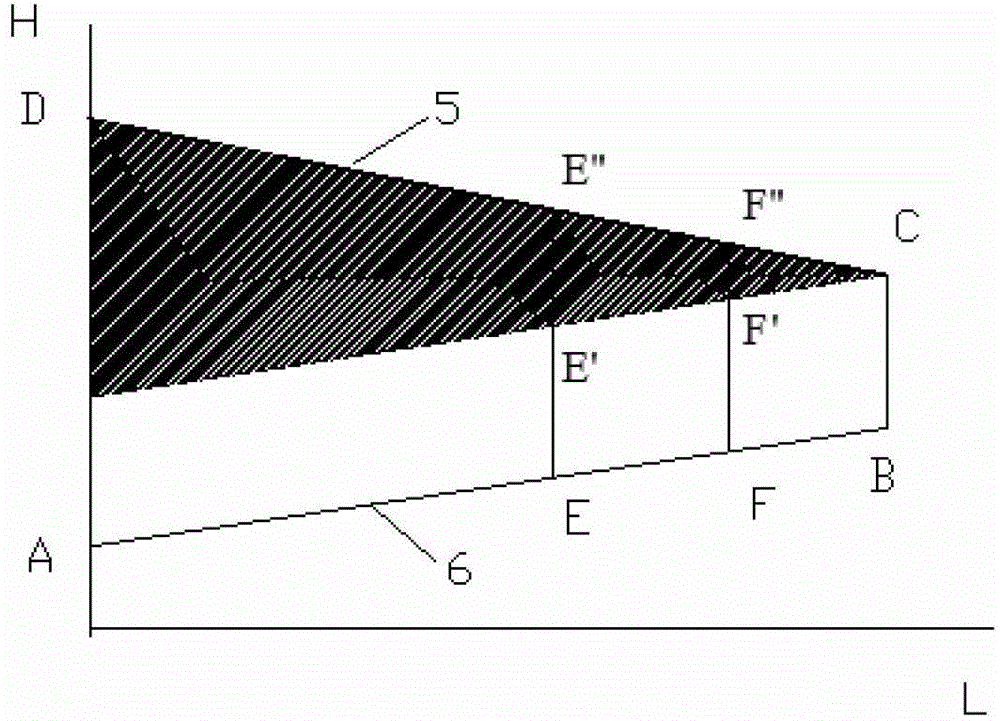

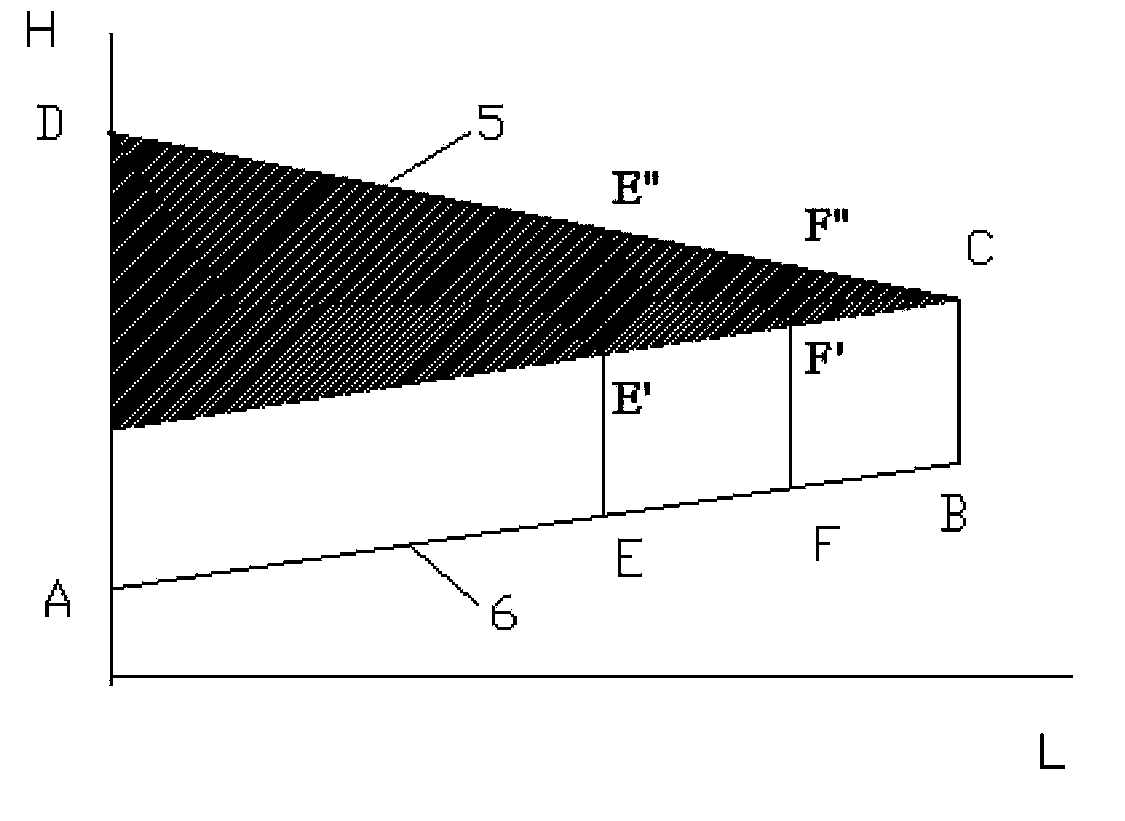

Distributed water mixing and pressurized heat supply system having decoupling function and design method of system

InactiveCN102966991AExcellent hydraulic stabilityReduce transportation energy consumptionLighting and heating apparatusSpace heating and ventilation detailsCouplingDifferential pressure

The invention discloses a distributed water mixing and pressurized heat supply system having a decoupling function and a design method of the system, relate to a heat supply system and a design method thereof, and aims to solve the problems of high invalid energy consumption and mutual coupling of hydraulic regimes existing in the conventional directly-connected centralized heat supply system, the problems of mutual coupling of hydraulic regimes and poor system adaptability existing in a distributed pump system, the problems of mutual coupling of hydraulic regimes and the presence of invalid energy consumption existing in the conventional water mixing system, and the problems of high invalid energy consumption and large diameter of an equalizer tank existing in an equalizer tank system. The distributed water mixing and pressurized heat supply system comprises a heat source, a heat source circulating water pump set, a water supply pipeline, a water return pipeline and three types of heat users, wherein the inlets of a first type of heat supply network users are provided with water mixing pumps and differential pressure valves; the inlets of a second type of heat supply network users are provided with water mixing pumps, booster pumps and decoupling equipment; and the inlets of a third type of heat supply network users are provided with water mixing pumps. The distributed water mixing and pressurized heat supply system is applied to heat supply systems.

Owner:HARBIN INST OF TECH +1

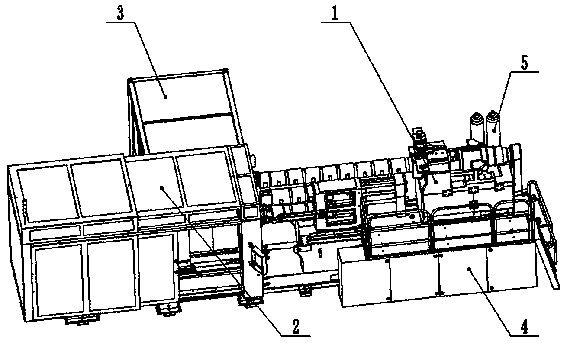

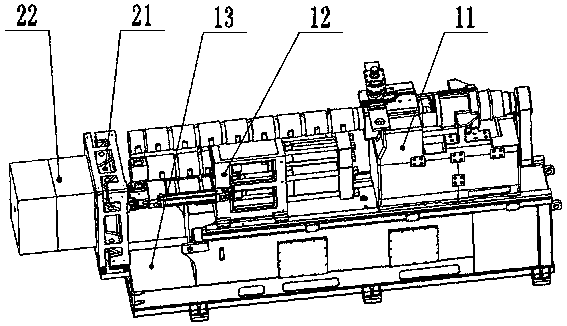

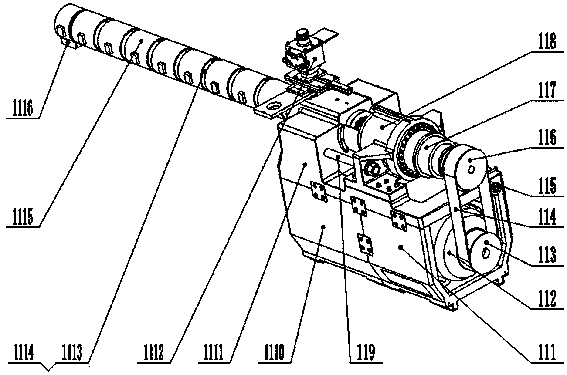

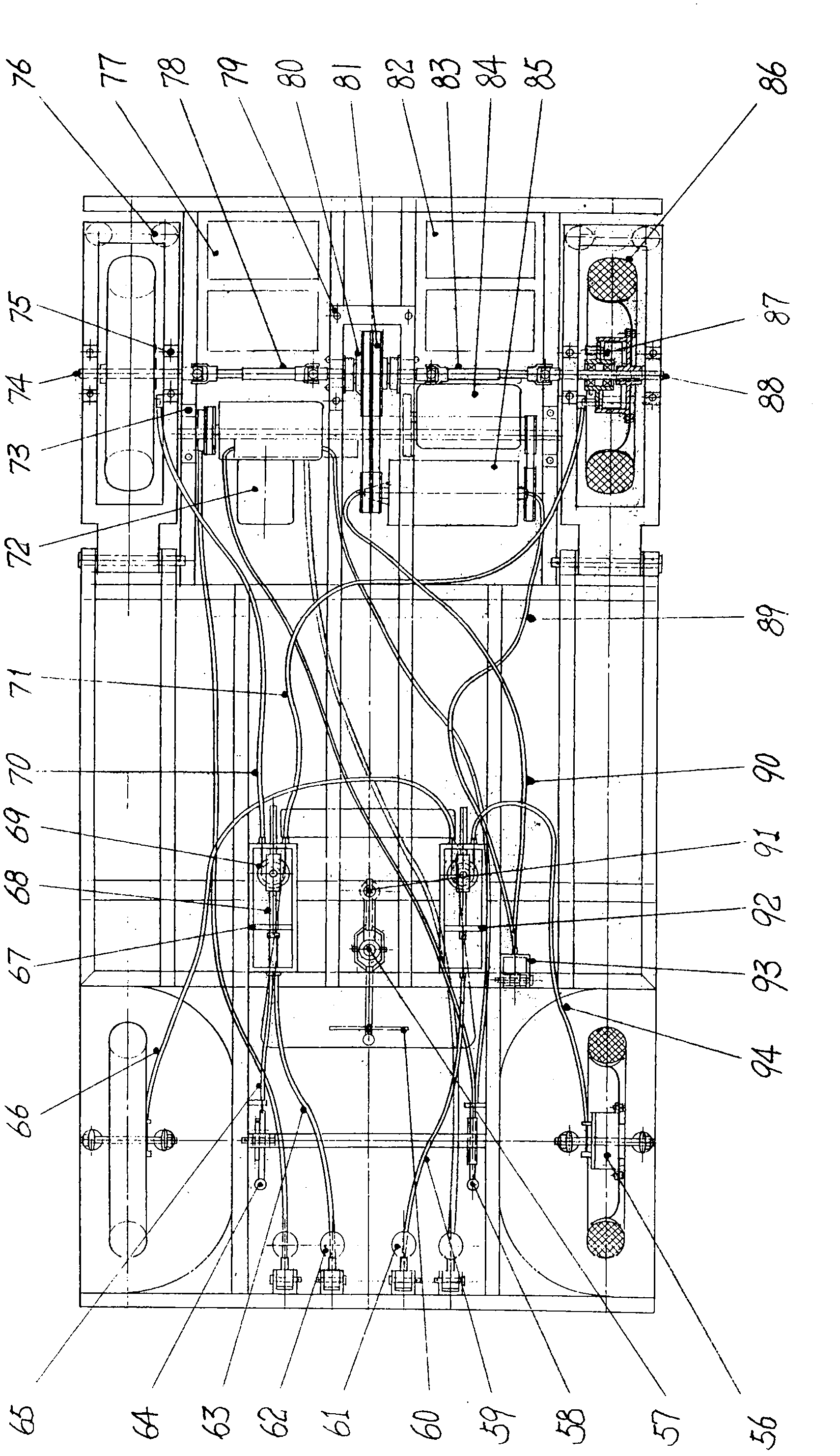

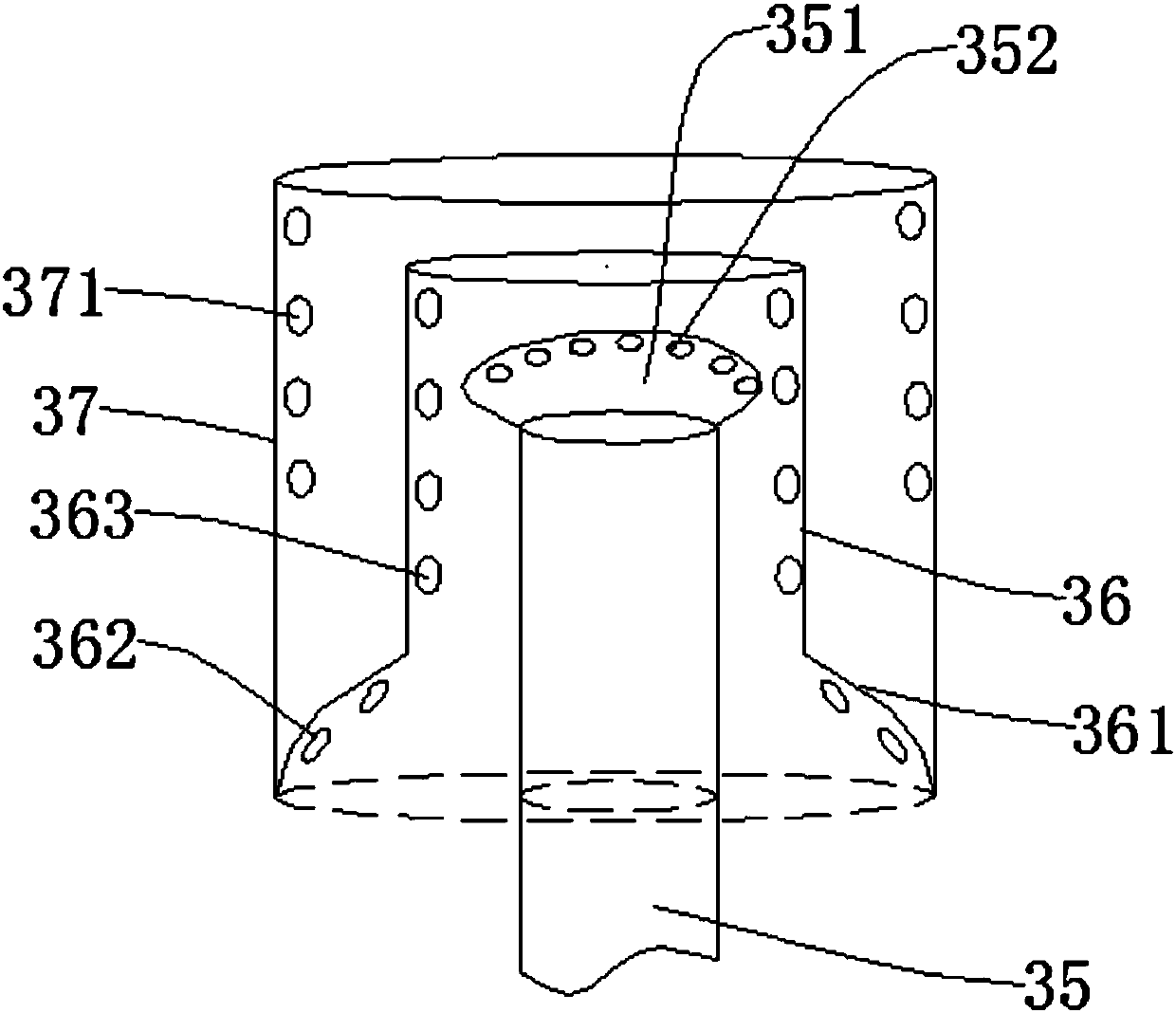

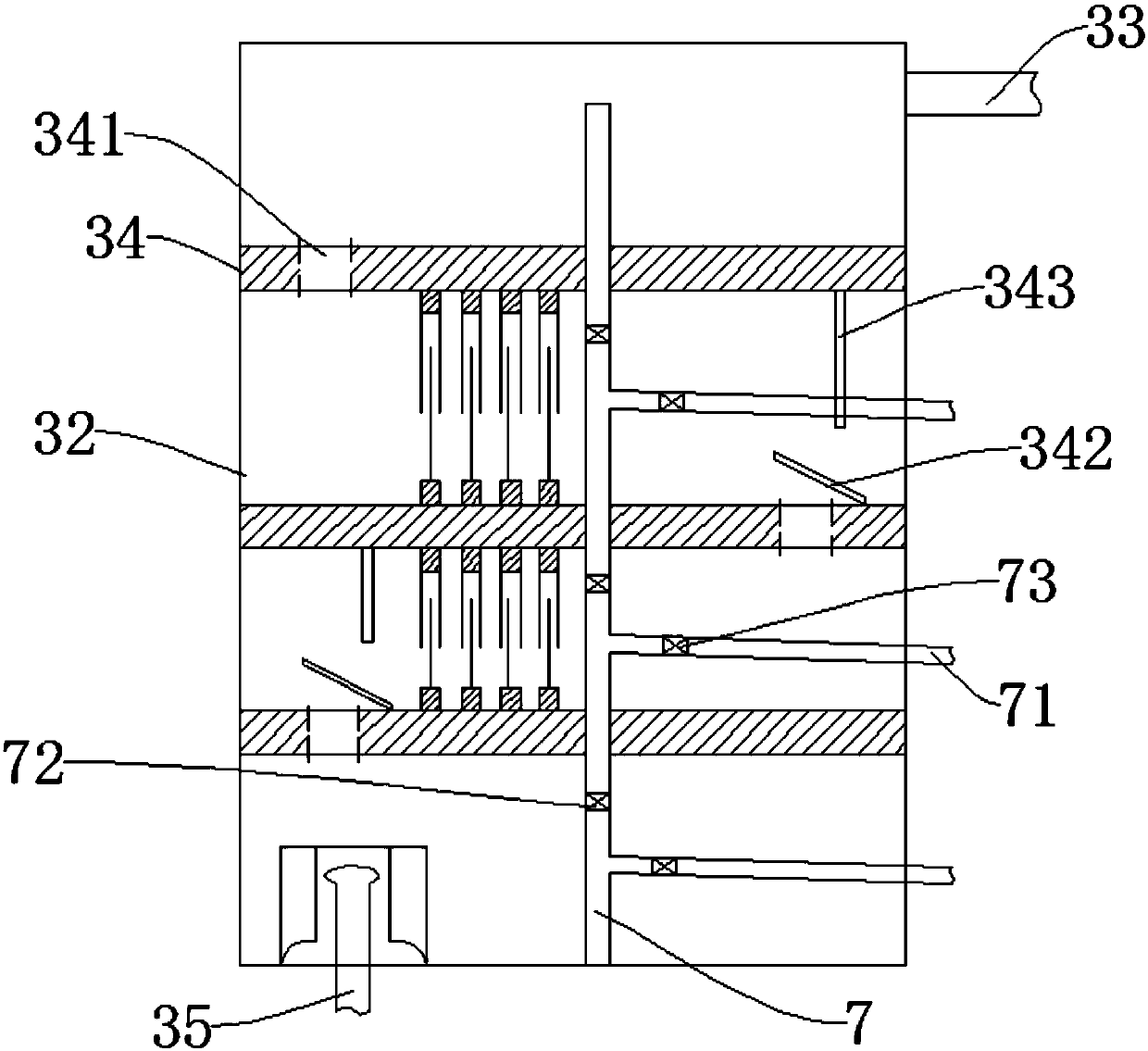

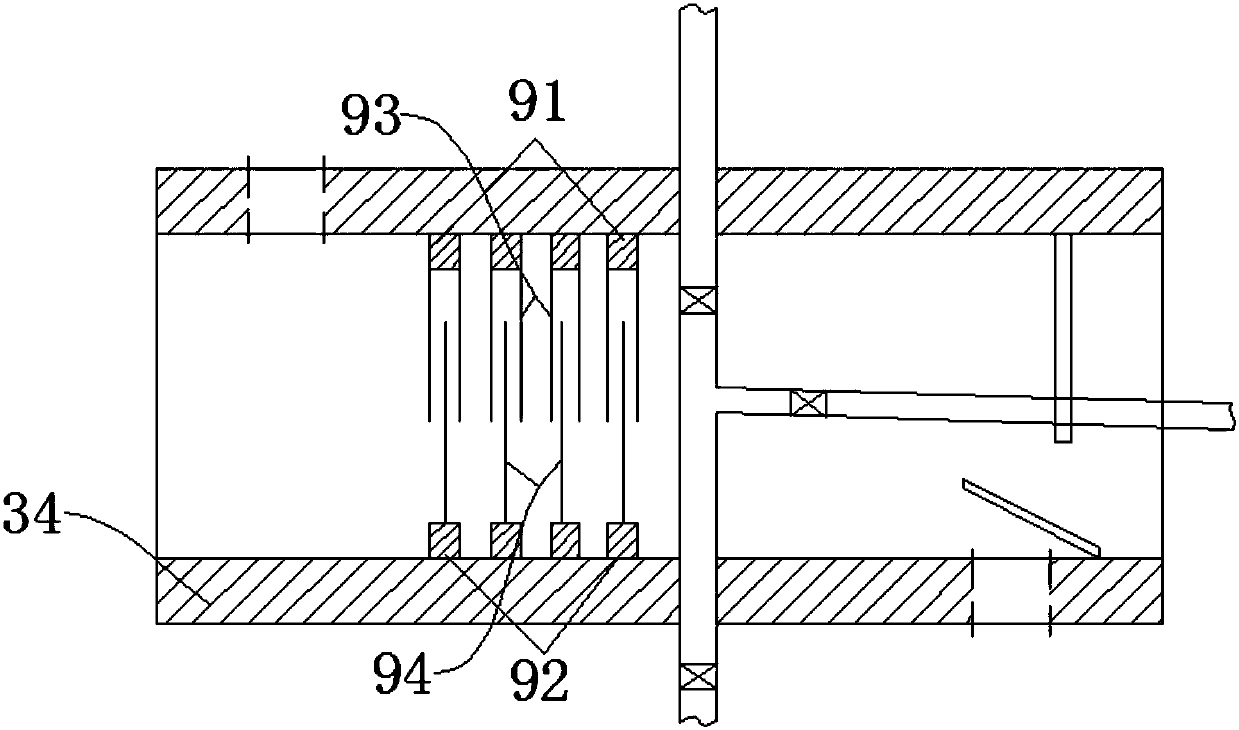

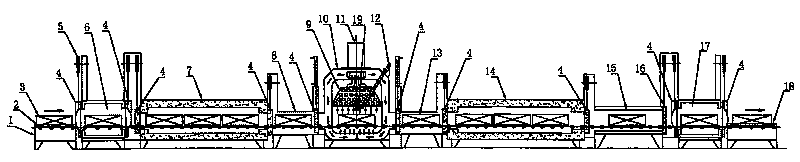

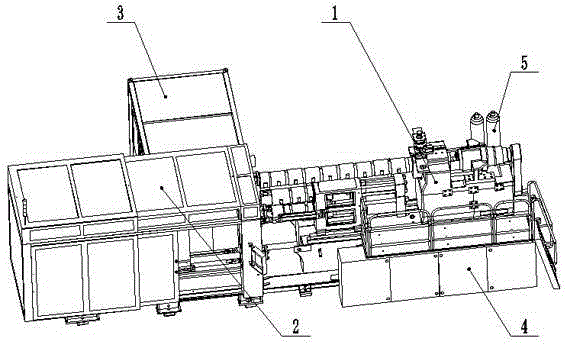

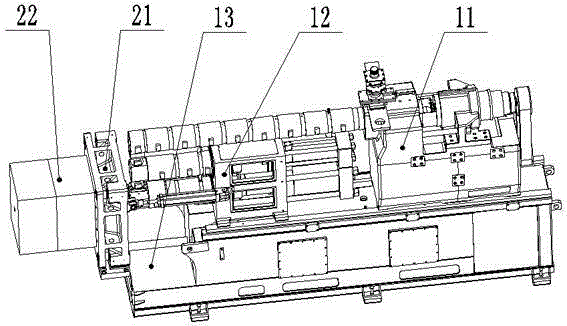

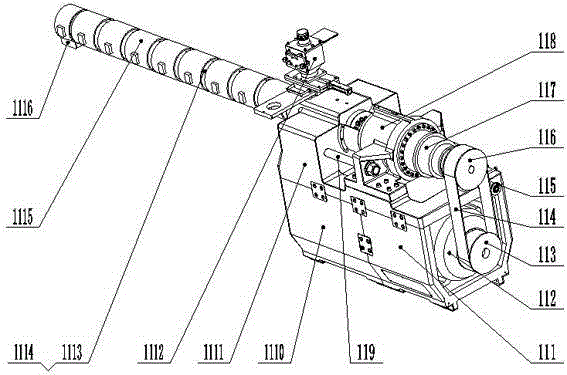

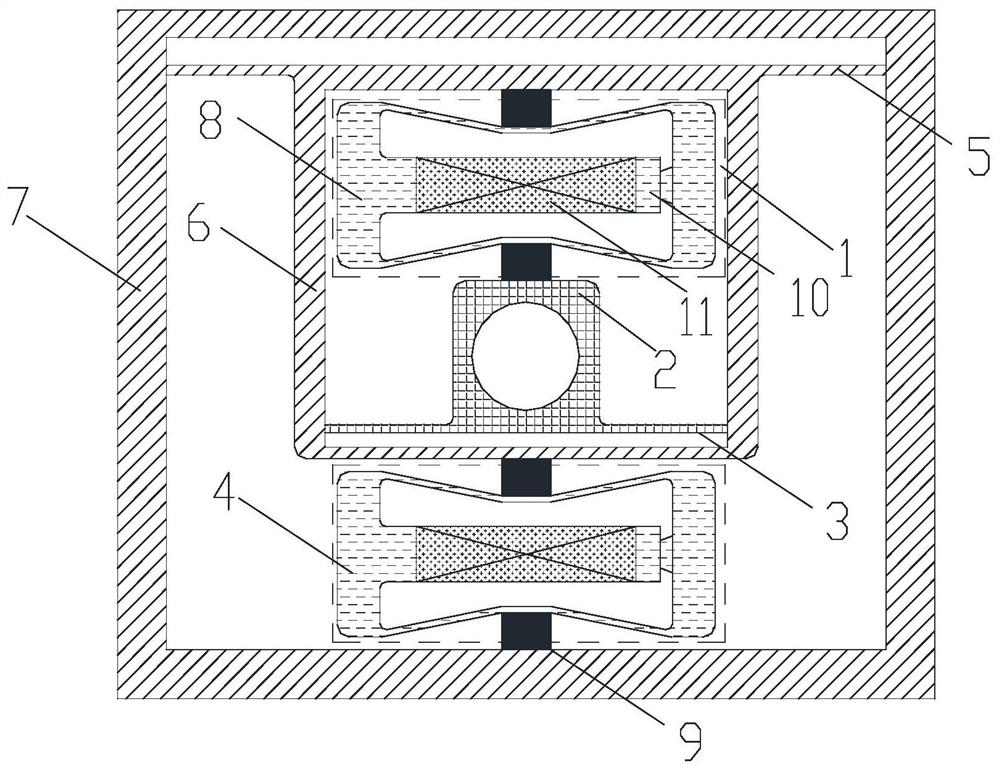

Graded storage injection molding machine

The invention provides a graded storage injection molding machine. The injection molding machine comprises a barrel capable of plasticizing the materials, a molten material tube, a storage cylinder capable of storing the material in a grading manner, and an injection cylinder, wherein plungers are flexibly sleeved in the storage cylinder and the injection cylinder respectively and connected with an oil cylinder, and the molten material tube is respectively and sequentially communicated with a discharge end of the barrel, the storage cylinder and the injection cylinder from the top to the bottom; a three-way change-over valve is arranged on the connection part of the molten material tube and the injection cylinder, and the injection cylinder is connected with a spray nozzle by the three-way change-over valve. The molten material which is plasticized by the barrel is stored in the storage cylinder and the injection cylinder in a grading manner, so that the plasticizing performance and the exhaust performance of the material are reliably ensured, and the quality of the materials is stable; simultaneously the barrel can continuously provide the molten material, and the plasticizing process of the materials and the quick filling of the storage cylinder with the molten material can be simultaneously performed in the machine injection pressure retaining period, so as to prepare for injection of the molten material in the next period. The graded storage injection molding machine is high-efficient and energy-saving and low in failure rate.

Owner:广东福能精密机械有限公司

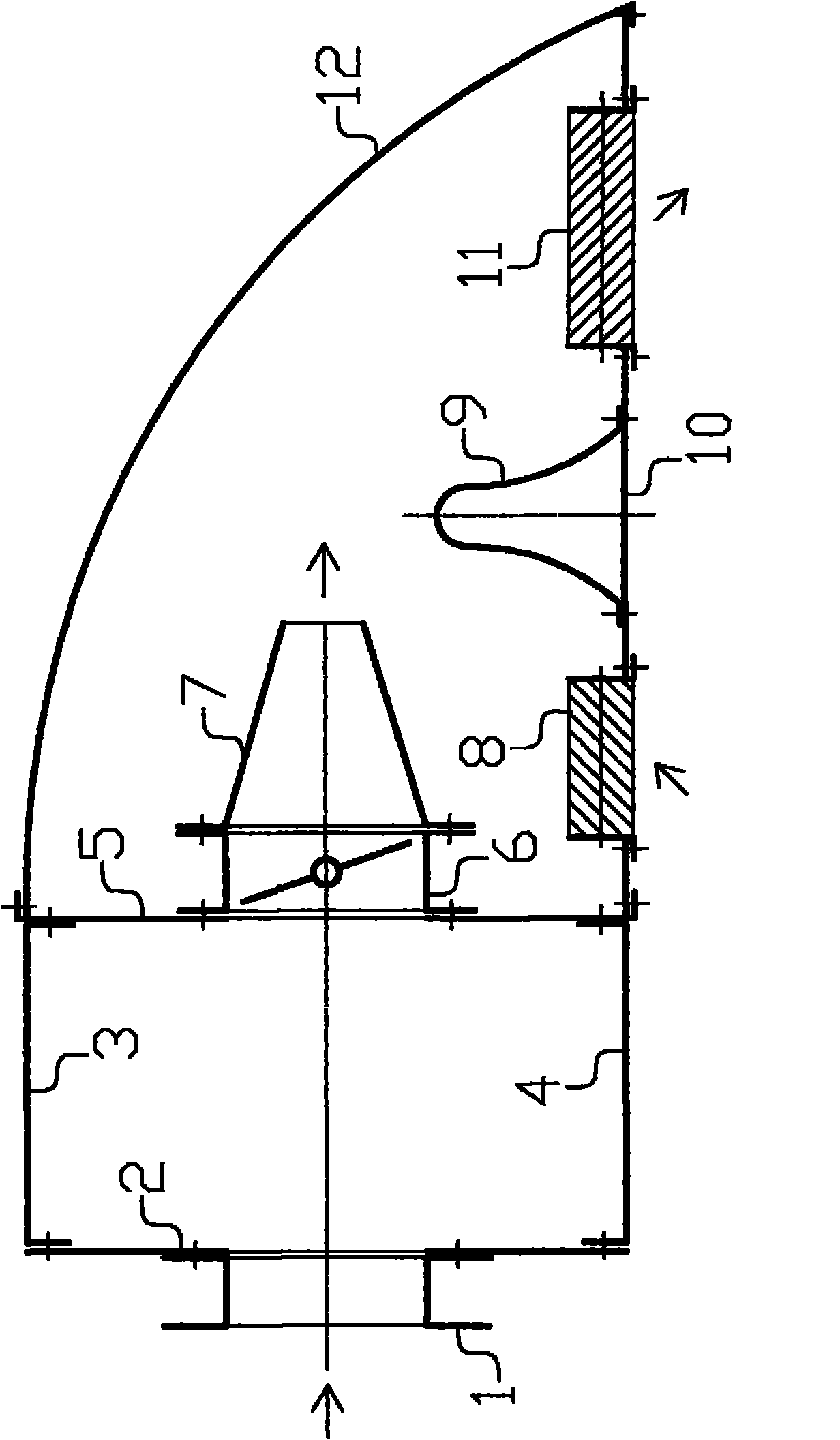

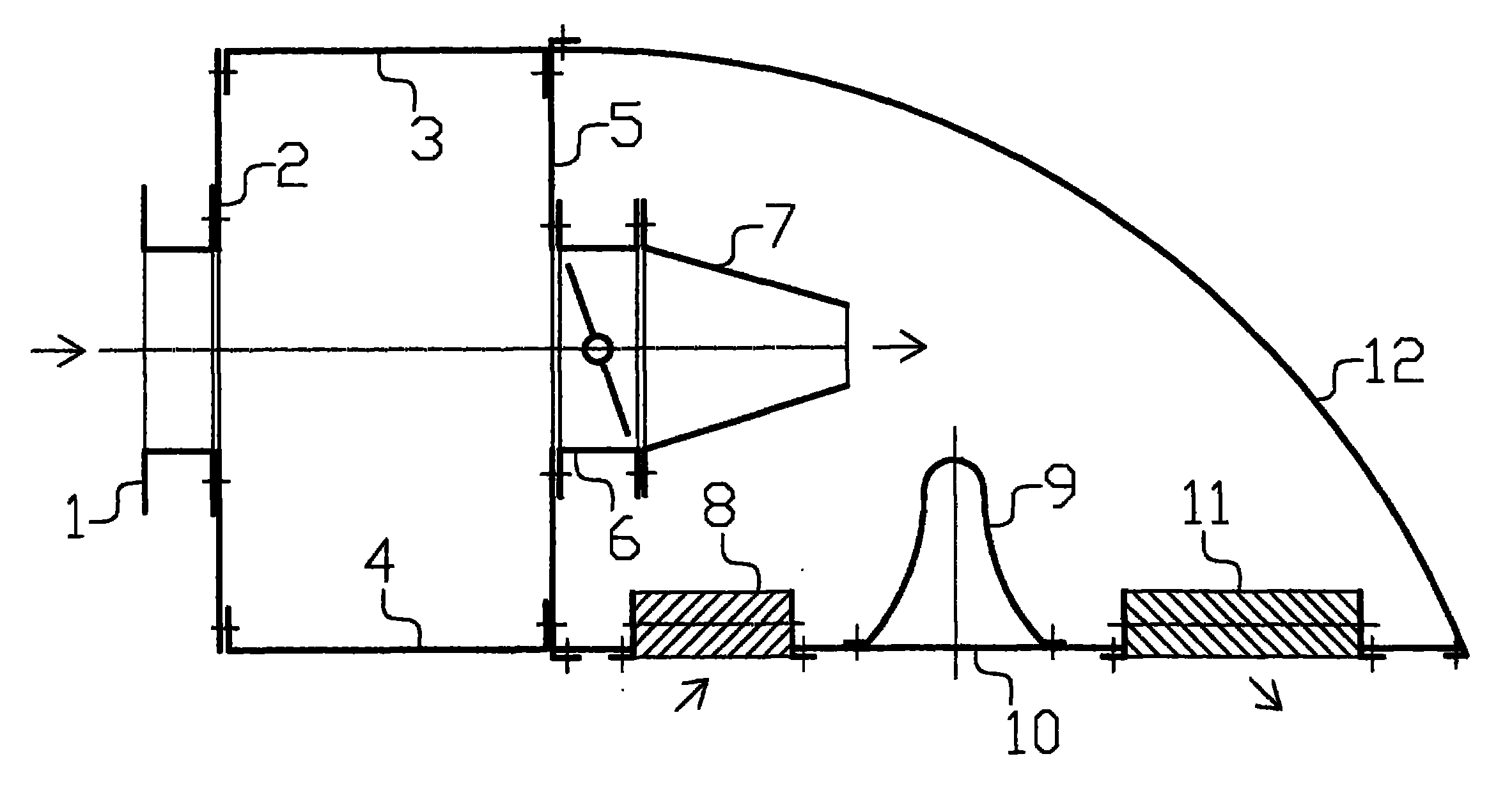

Low-temperature air supply device

InactiveCN102213479APlay the role of equalizing and stabilizing voltageReduce ineffective energy consumptionDucting arrangementsSpace heating and ventilation safety systemsJet flowAir volume

The invention relates to a low-temperature air supply device which comprises an inlet air pressure equalizing box structure part, an air supply adjusting and inducing box structure part and a built-in heat-insulation layer, wherein the inlet air pressure equalizing box plays the roles of equalizing and stabilizing the pressure of an air supply pipe network of a central air conditioner and is convenient for adjustment of the air output for each room; the air supply adjusting and inducing box consists of an electric adjusting valve, a jet tapering air port, an air return port, an Omega-shaped backpressure plate, an air supply port and a box body plate; under the action of high-speed jet airflow, an air return negative pressure region and an air supply positive pressure region in the box are formed; air in each room is induced by the negative pressure to enter the box via the air return port and is mixed with the low-temperature air jet; and the mixed airflow enters the positive pressure air supply region after temperature rise and is fed to the room through the air supply port; and therefore, according to the low-temperature air supply device disclosed by the invention, the actual problems that the air output is adjusted as required in each room, condensed water is generated in the air supply port, and the like are solved.

Owner:BEIJING SHUIMU ZEQING ENERGY TECH

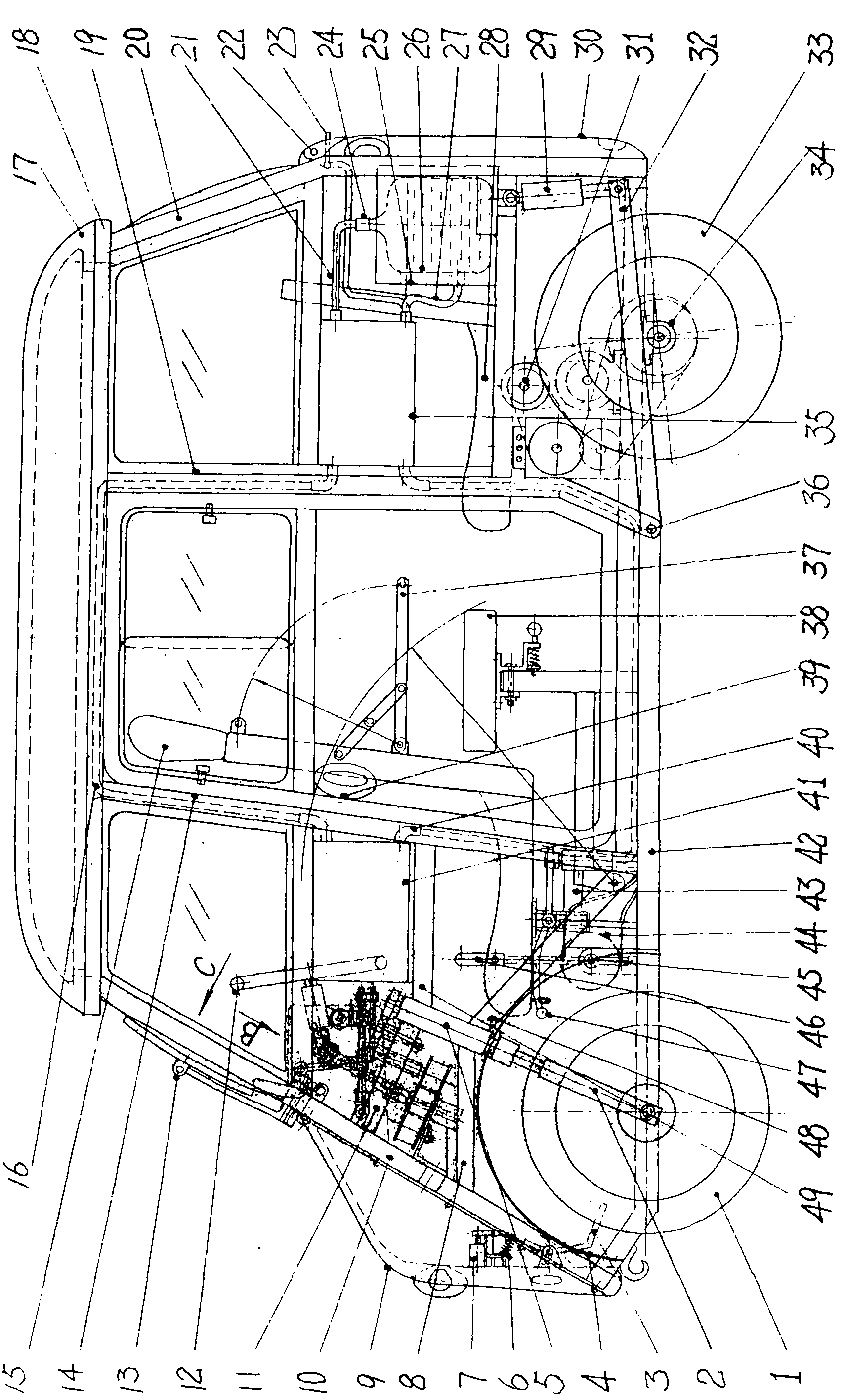

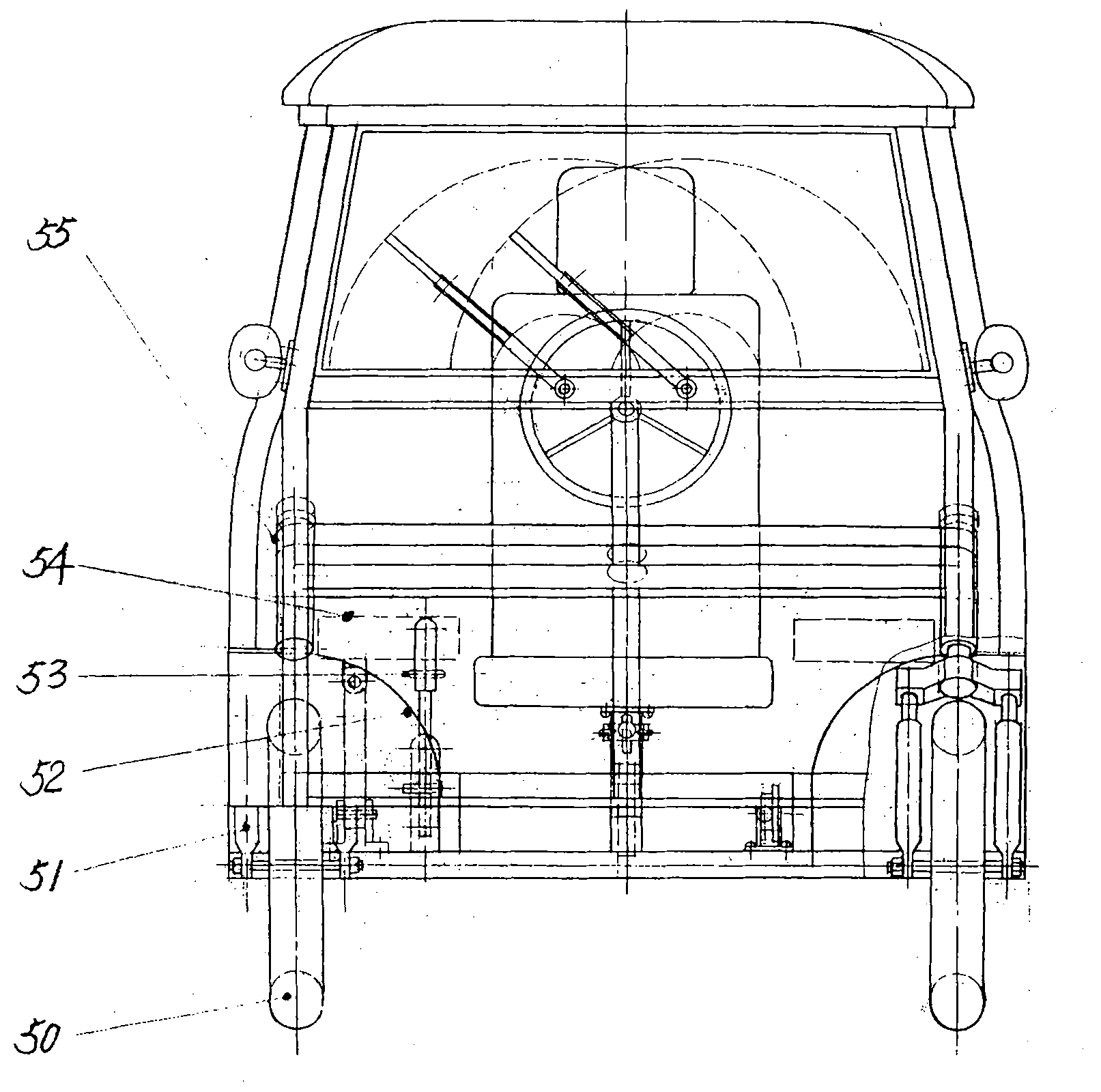

Hybrid miniature car

InactiveCN102320239AEasy to manufactureSimplify the assembly processAir-treating devicesMechanical steering gearsLine tubingSteering wheel

The invention discloses a hybrid miniature car adopting electric and fuel oil power drives which can be mutually converted. The hybrid miniature car which is provided with a lead-acid storage battery can run 60-70km on a single charge, and the route of the hybrid miniature car can be increased to 200km with the adoption of the fuel oil drive; the hybrid miniature car has a weight of about 300kg and can hold 5 persons; the hybrid miniature car is provided with three forward gears, one neutral position and one reverse gear and has a maximum velocity of 80km; a push-pull type door (8) is arranged at each of two sides of a closed cab of the hybrid miniature car; a rotary driver seat (7), a folding table (10), two bilateral folding seats (9), a twin seat (11), a heating installation, and the like are arranged in the cab; a shock fork (5) for installing front wheels (6) is assembled with a frame sleeve (4) and linked with a steering wheel (1) via a universal shaft (2) and a link mechanism (3); a wheel stand (13) for installing back wheels (17) is assembled with a frame via a pin shaft (12) and a shock absorber (19); a direct-current motor (16) and a gasoline engine differentially drive two back wheels respectively via a belt, a power conversion device (15), a transmission (14), a differential mechanism and left and right universal shafts thereof; and left and right service brakes are respectively braked via a brake pipeline, a balanced brake and front and back wheel expansion brakes.

Owner:陈茹

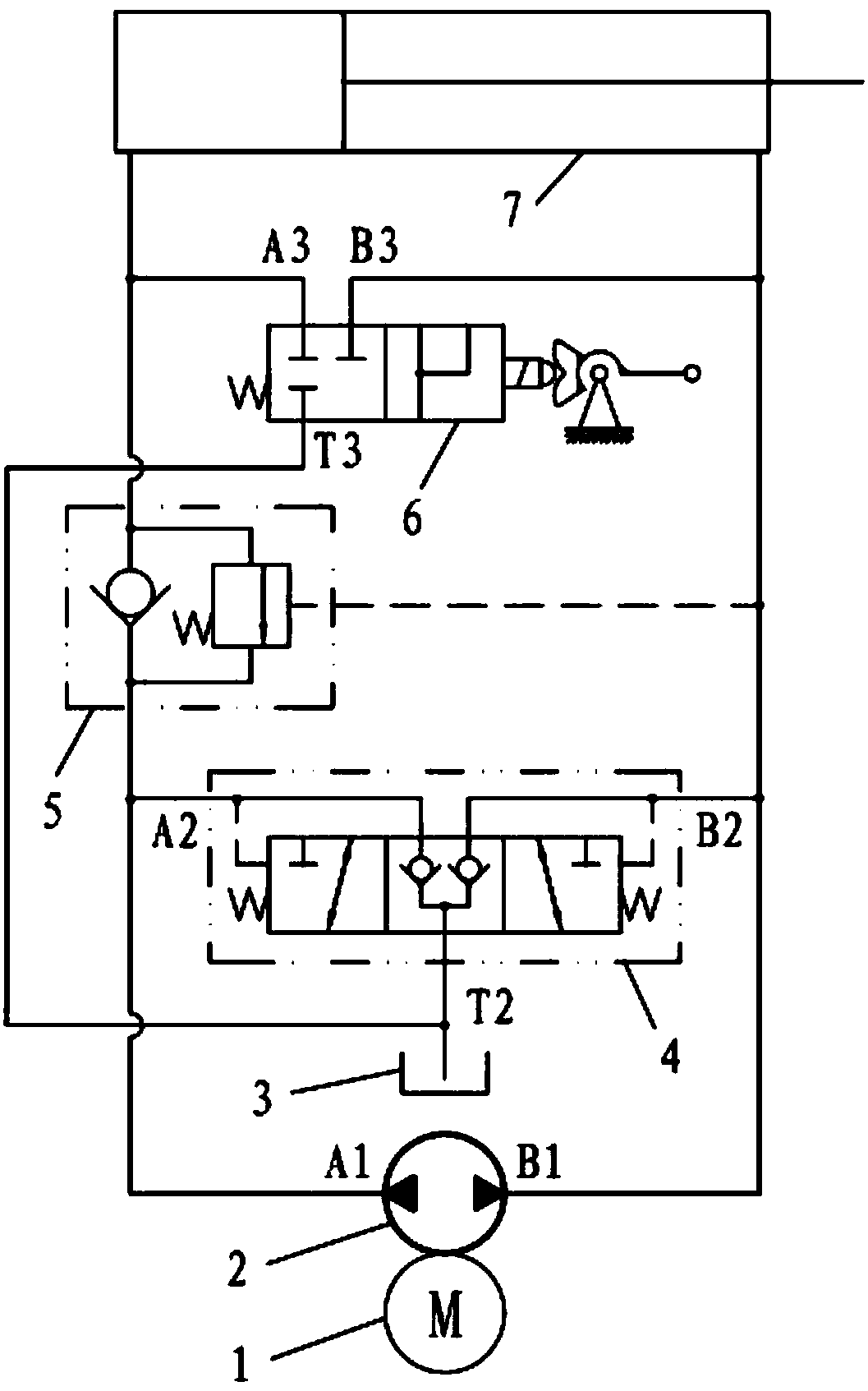

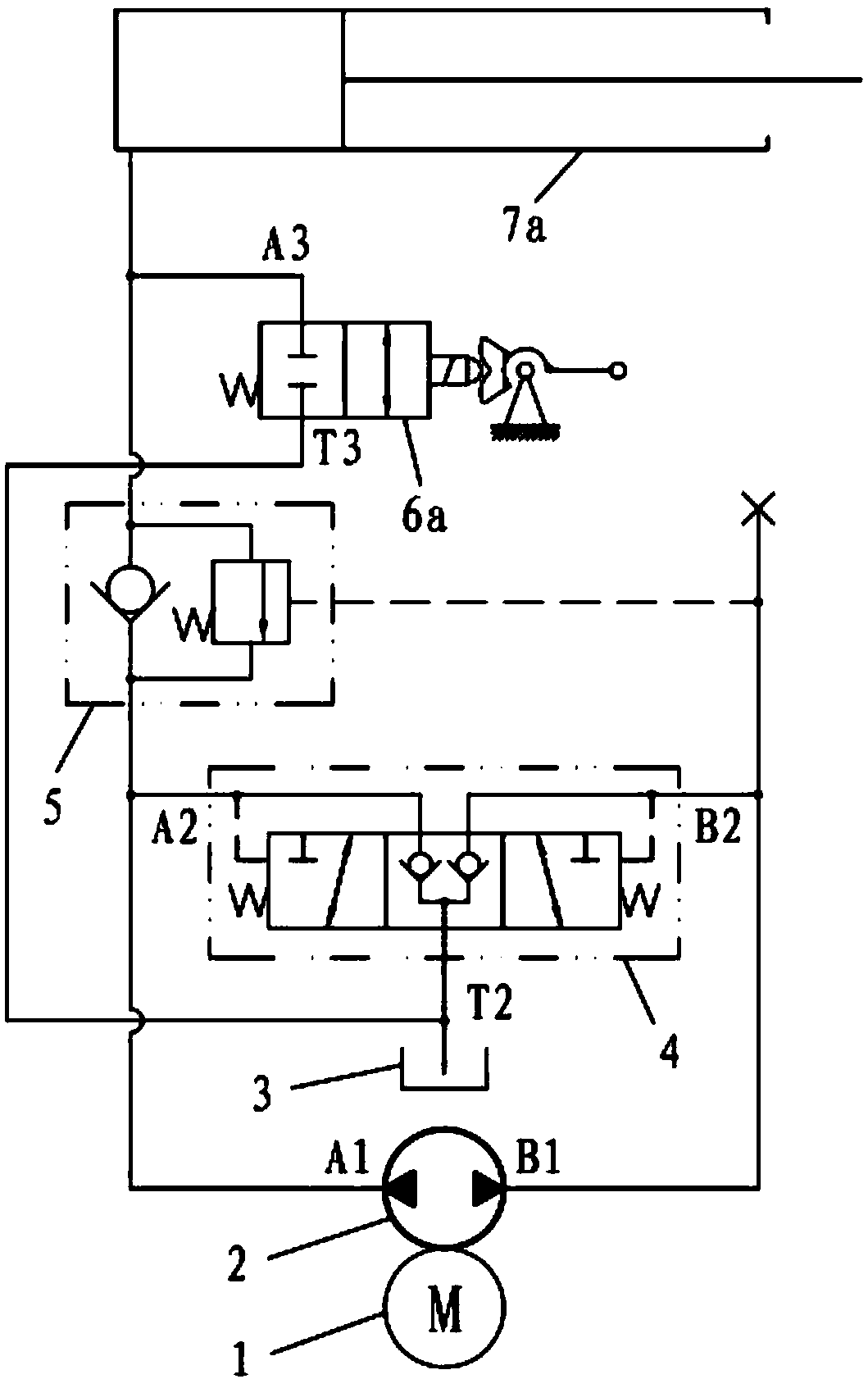

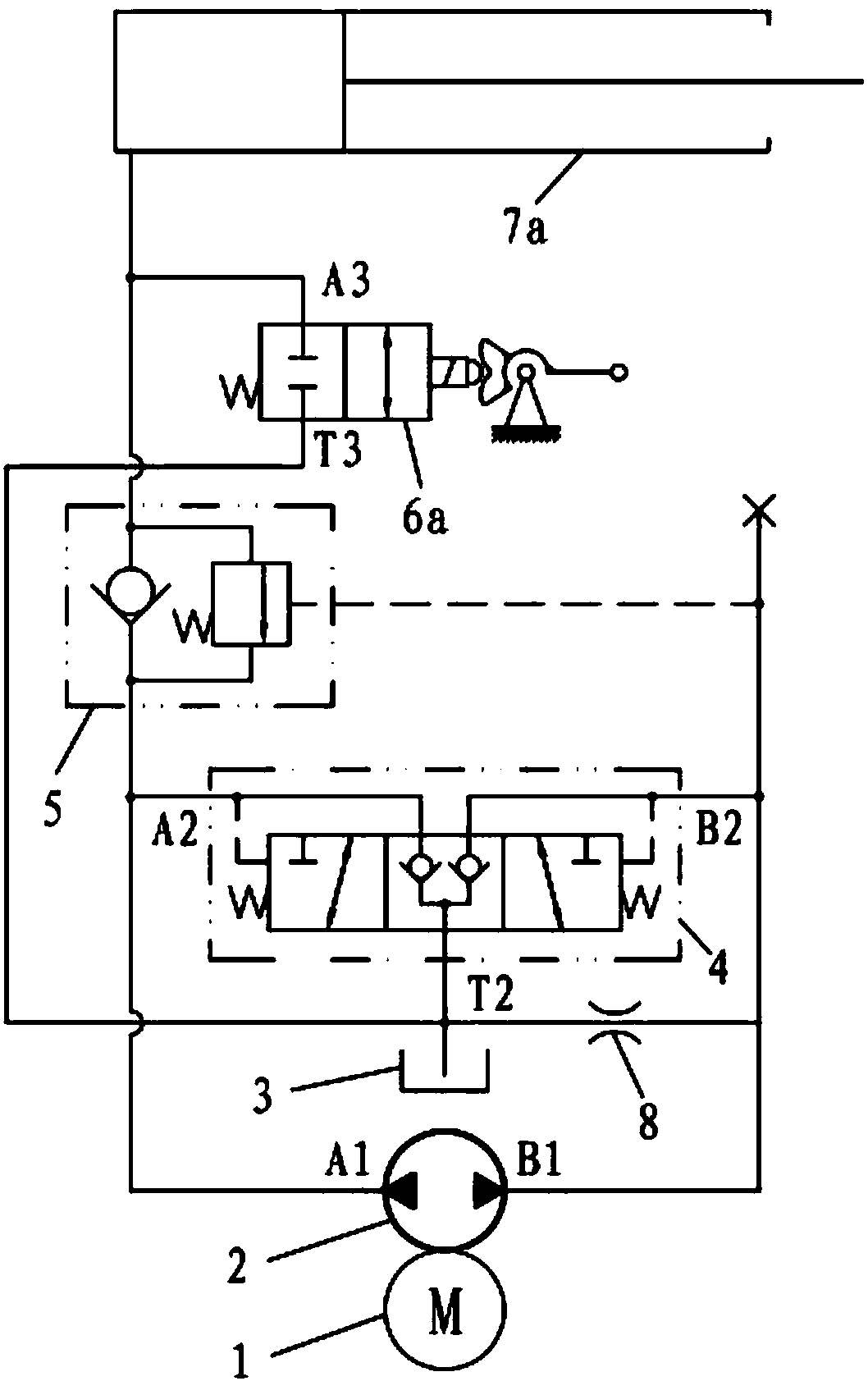

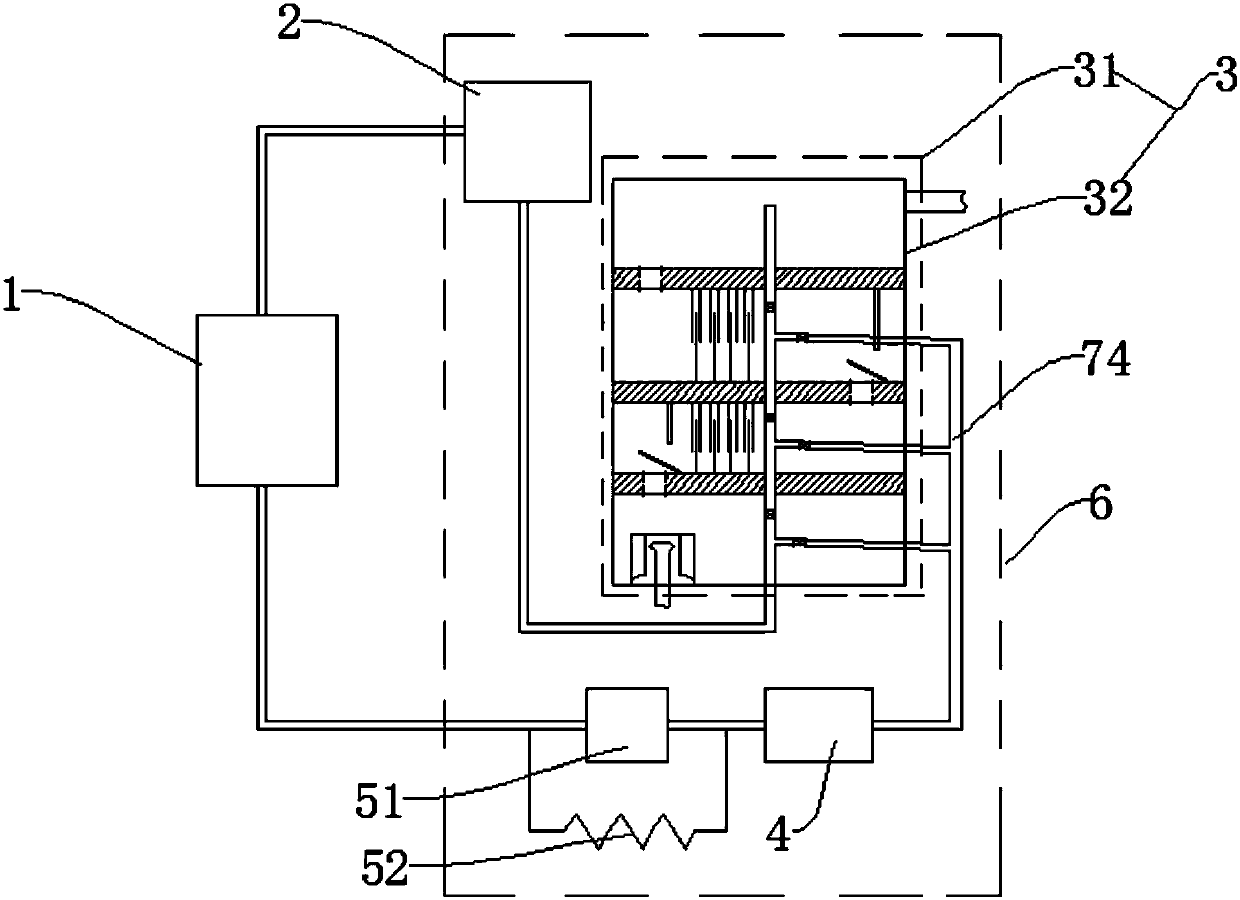

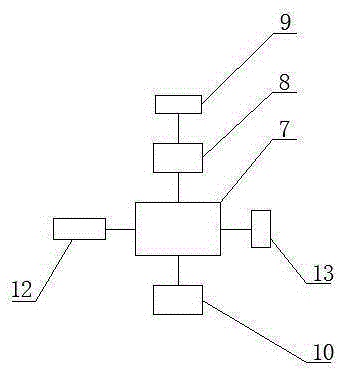

Pump-controlled hydraulic transmission system applied to exoskeleton robot

PendingCN108488114AReduce ineffective energy consumptionImprove transmission efficiencyServomotor componentsServomotorsExoskeleton robotHydraulic pump

The invention discloses a pump-controlled hydraulic transmission system applied to an exoskeleton robot. The pump-controlled hydraulic transmission system comprises a servo motor, a bidirectional hydraulic pump, a flow match valve, a power-assisted function switch valve, an oil cylinder and an oil container. The servo motor is adopted to drive the bidirectional-rotation hydraulic pump, reversing and speed adjusting of an executing mechanism are achieved through adjustment of the motor rotation direction and rotation speed, the demand pressure of the executing mechanism is matched with the workpressure of the hydraulic pump in real time, unavailable energy consumption is small, and the transmission efficiency can be improved substantially.

Owner:GUIYANG HAIZHILI HYDRAULIC CO LTD

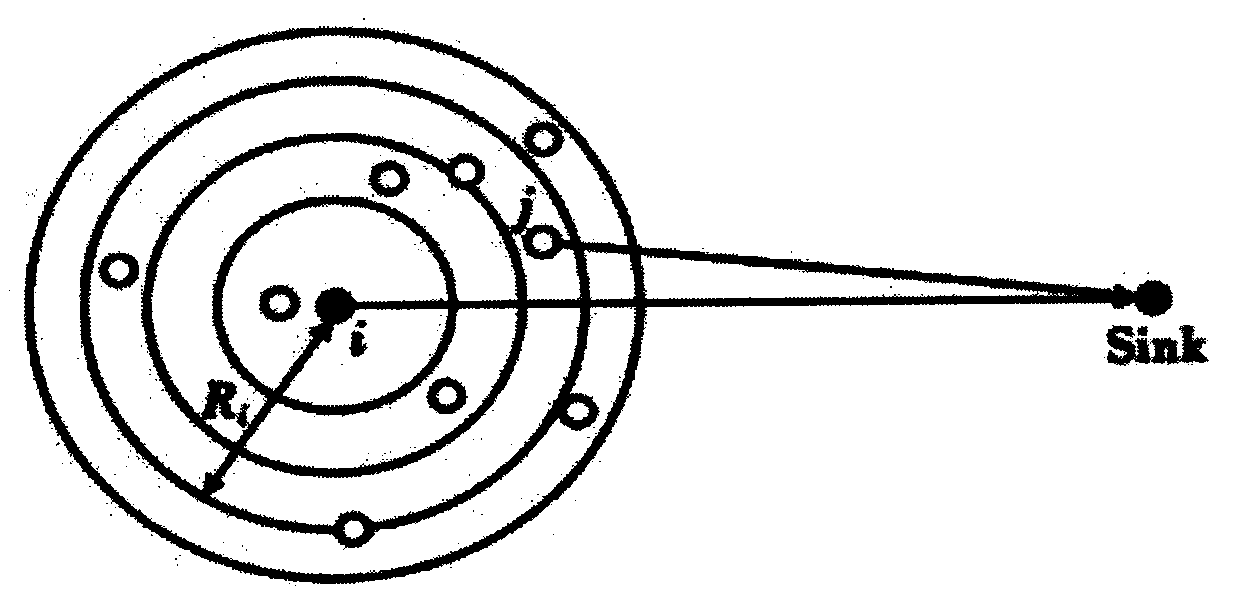

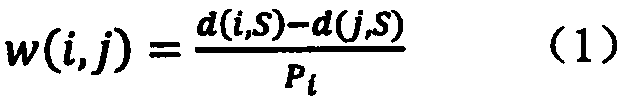

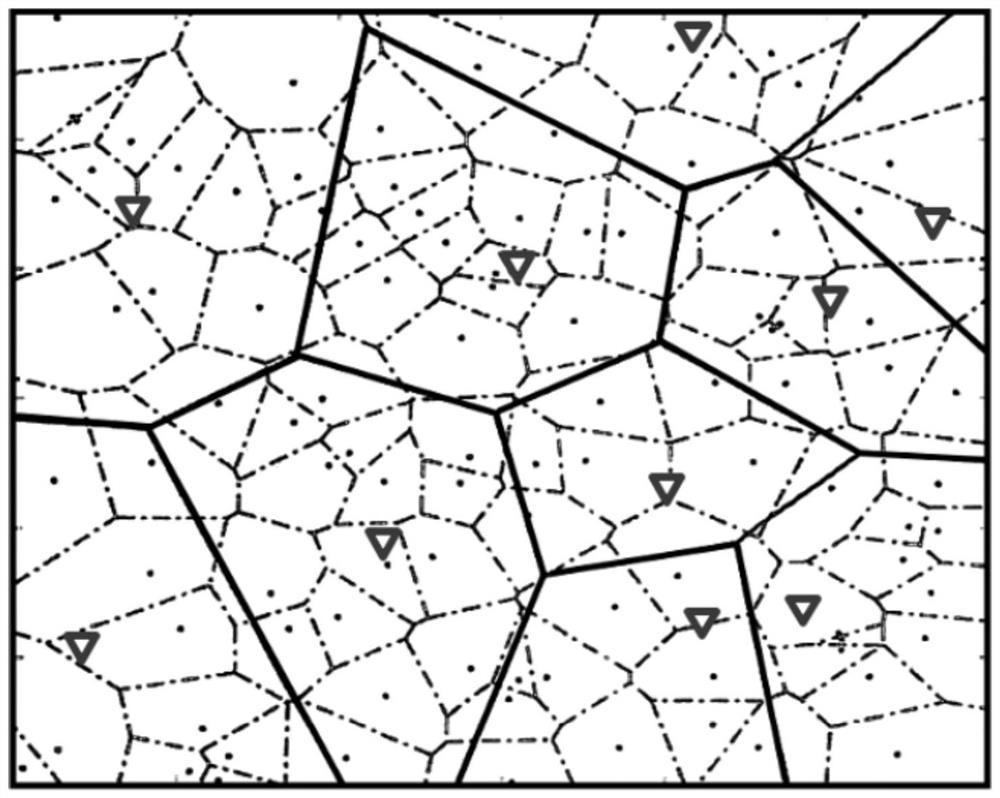

Directed spanning tree cross-layer communication method based on power control

InactiveCN108696880ASolve the problem of ineffective energy consumptionControl transmission powerPower managementNetwork topologiesBalancing networkGeolocation

The invention provides a directed spanning tree cross-layer communication method based on power control, which is characterized in that the method comprises the following steps: first, establishing adirected spanning tree model based on geographical position information; and second, establishing a cross-layer node transmission power control model and solving an optimal node transmission power solution set. The invention adopts a directed spanning tree algorithm to solve the problem of invalid energy consumption in the data transmission process and controls the transmission power of nodes to reduce the network communication competition intensity. Compared with other schemes in the same field, the invention can effectively balance the energy consumption and the reliability of the network communication and meets the requirement of long-time high robustness of a wireless sensor network.

Owner:SHANGHAI DIANJI UNIV

Efficient energy-saving air energy water heater

The invention discloses an efficient energy-saving air energy water heater. The efficient energy-saving air energy water heater comprises an evaporator, a compressor, a condenser, a filter and an expansion valve which are connected in a circulating mode through a refrigerant pipeline, and further comprises a water tank, a plurality of partitions, and a condensing tube, wherein a hot water outlet tube is arranged at the upper end of the water tank; a cold water inlet tube and a refrigerant inlet are arranged at the lower end of the water tank; the upper end of the cold water inlet tube communicates with a spherical part; a first sleeve sleeves the cold water inlet tube; a second sleeve sleeves the first sleeve; the partitions are used for dividing the inner part of the water tank into a plurality of spaces, and an arc-shaped hole is formed in each partition; the condensing tube passes through the partitions from bottom to top, the part, positioned in each space, of the condensing tube communicates with a first branch tube; and the first branch tubes extend out of the water tank and communicate with a second branch tube outside the water tank. According to the water heater disclosedby the invention, the spherical part, the first sleeve and the second sleeve are equipped with a plurality of guide holes for reducing flow speed of cold water entering the water tank, so that mixingspeed of original hot water in the water tank and cold water is reduced, and a hot water utilization rate is increased.

Owner:广西昊薪来新能源有限公司

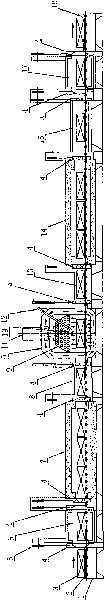

Brilliant isothermal normalizing production system

ActiveCN101363071AReduce ineffective energy consumptionSolve the problem of serious burning loss and oxidationNuclear engineeringCooling chamber

The invention relates to a bright isothermal normalizing production system which comprises a feeding table, a normalizing heating furnace, a sealed fast cooling chamber, an isothermal furnace, a water cooling chamber and a discharge table, wherein, the feeding table, the normalizing heating furnace, the sealed fast cooling chamber, the isothermal furnace, the water cooling chamber and the discharge table are sequentially connected to form a run-through inner cavity inside; a front vacuum chamber is arranged between the feeding table and the normalizing heating furnace, a transition chamber is arranged between the normalizing heating furnace and the sealed fast cooling chamber, a rear transition chamber is arranged between the sealed fast cooling chamber and the isothermal furnace, and a rear vacuum chamber is arranged between the water cooling chamber and the discharge table; sealing doors are respectively arranged at openings at two ends of the normalizing heating furnace, the sealed fast cooling chamber, the isothermal furnace, the front vacuum chamber and the rear vacuum chamber; and a water cooling chamber door is arranged at the end face of the opening of the water cooling chamber close to the rear vacuum chamber. The production system has the beneficial effect of no oxidization of the heat treated products, small hardness scattering difference, saving energy and materials, solving the problems of unstable product quality and severe burning loss and oxidization of steel products. The bright isothermal normalizing realizes the ideal effect of high quality, energy and materials saving, and environmental protection.

Owner:HANGZHOU JINZHOU TECH CO INC

Throttling air energy water heater

PendingCN107606788AIncrease profitSlow down the mixing speedFluid heatersMechanical apparatusEngineeringThermal water

The invention discloses a throttling air energy water heater. The throttling air energy water heater includes an evaporator, a compressor, a condenser, a filter and an expansion valve which are connected with one another through a refrigerant pipeline in a circulation mode. The throttling air energy water heater also includes a water tank, multiple dummy plates, magnetizing components and a condensation pipe, wherein the upper end of the water tank is provided with a hot water outlet pipe and the lower end of the water tank is provided with a cold water inlet pipe and a refrigerant inlet; a spherical part is installed at the upper end of the cold water inlet pipe; a first sleeve is externally installed on the cold water inlet pipe in a sleeving mode; a second sleeve is externally installedon the first sleeve in a sleeving mode; the interior of the water tank is divided into multiple spaces by the dummy plates and each dummy plate is provided with an arc-shaped hole; the magnetizing components are installed between the dummy plates; the condensation pipe penetrates through the multiple dummy plates from bottom to top; each part, located in each space, of the condensation pipe communicates with a first branch pipe and the multiple first branch pipes communicate with second branch pipes located outside the water tank. According to the throttling air energy water heater, the flowspeed of cold water entering the water tank is reduced through guiding holes formed in the exteriors of the spherical part, the first sleeve and the second sleeve so that the mixing speed of originalhot water and the cold water in the water tank is reduced, and the use ratio of the hot water is increased.

Owner:广西昊薪来新能源有限公司

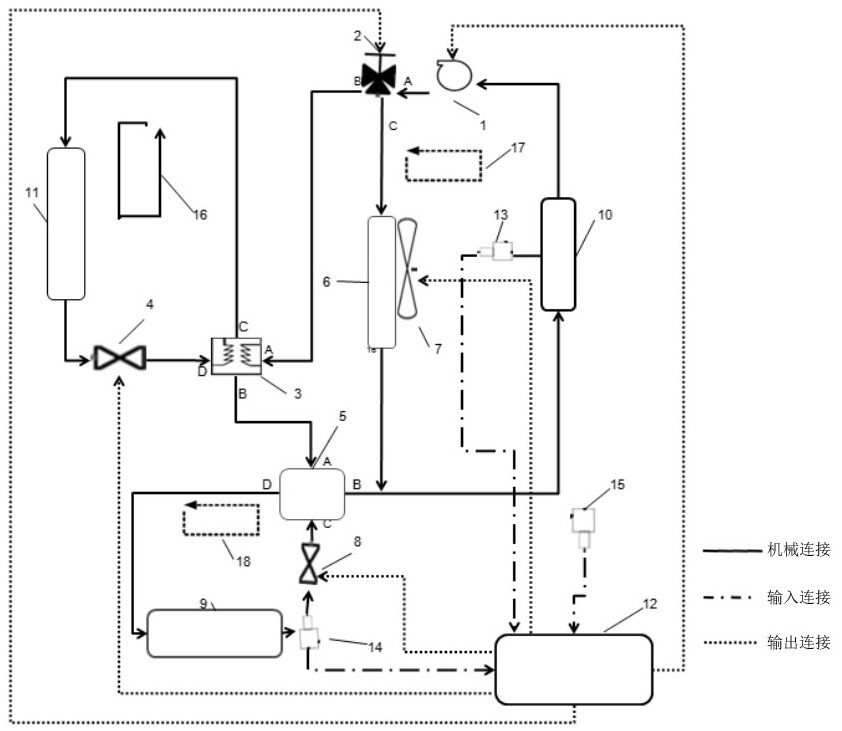

Thermal management control system and control method for battery pack of hybrid electric vehicle

PendingCN113581013AHigh development maturityLow costVehicular energy storageBattery/fuel cell control arrangementHeat managementPlate heat exchanger

The invention discloses a thermal management control system and method for a battery pack of a hybrid electric vehicle. The control system comprises an engine cooling control module, an air conditioner refrigerant control module and a battery pack thermal management control module. The engine cooling control module comprises an engine waterway assembly, an engine water temperature sensor, a one-way valve and a heat exchanger which are sequentially connected in series; the air conditioner refrigerant control module comprises an air conditioner system assembly, an electronic expansion valve and a refrigerant plate heat exchanger which are sequentially connected in series; and the battery pack thermal management control module comprises a battery pack internal waterway assembly, an electronic water pump, a two-position three-way electromagnetic valve, a refrigerant plate heat exchanger and a heat exchanger which are sequentially connected in series. According to the control system, four thermal management control modes of pre-cooling at medium and low temperature, high-efficiency heat exchange cooling at high temperature, heating at extremely low temperature and energy balance of the battery cell are designed, so that the battery pack can be freely switched between an energy-saving mode and a high-efficiency mode along with changes of an external environment, a whole vehicle load and the temperature of the battery cell, and invalid energy consumption of the battery pack is reduced.

Owner:JIANGLING MOTORS

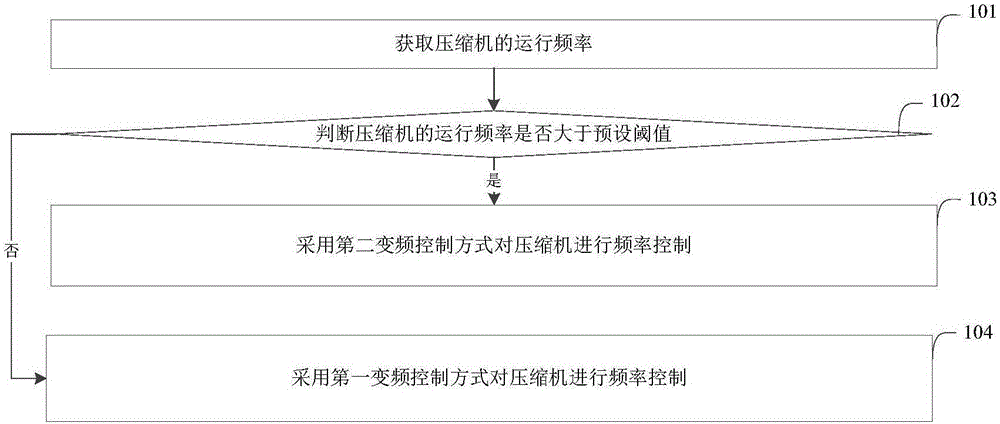

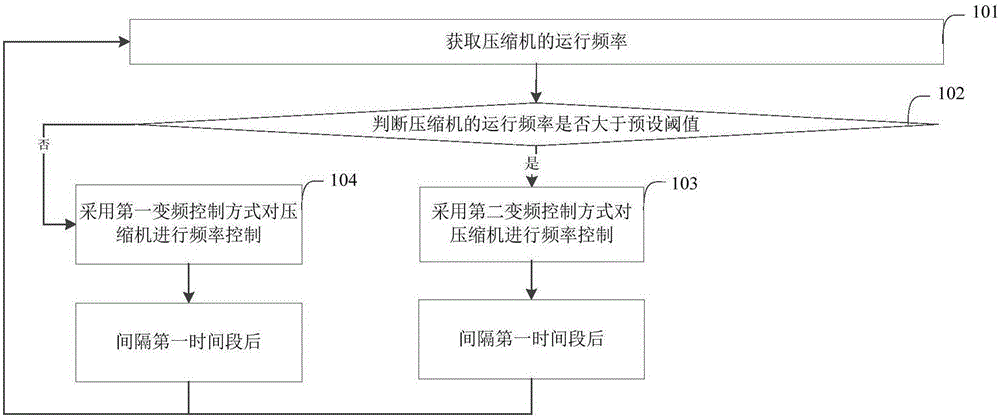

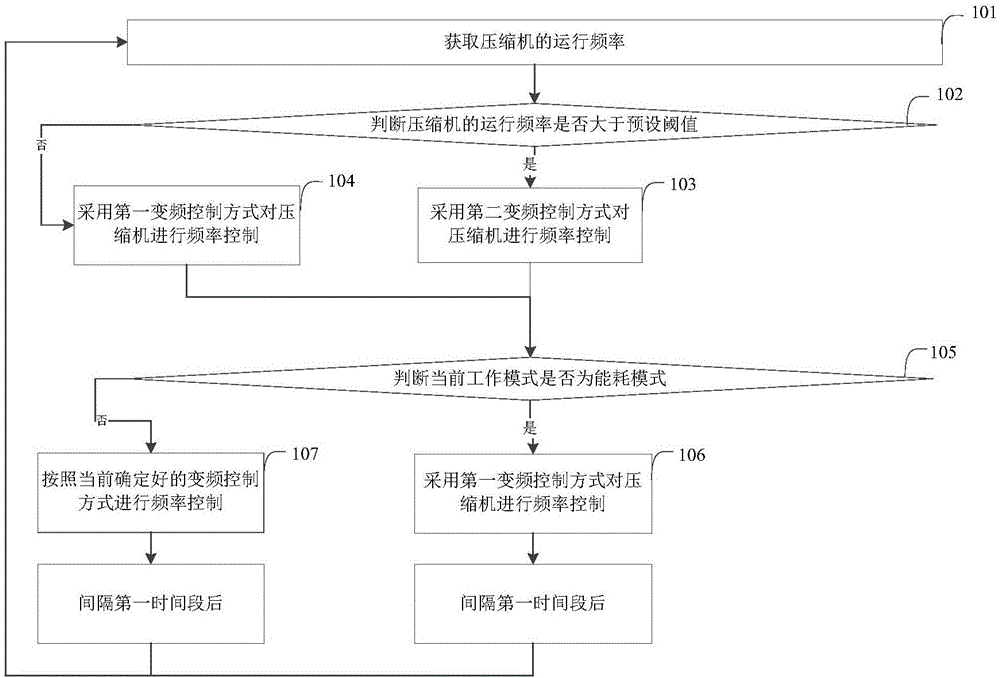

Frequency converting control method, controller and refrigerator

InactiveCN106286249AReduce energy consumptionReduce noiseMotor parameterPump controlControl mannerVariable frequency control

The invention provides a frequency converting control method, a controller and a refrigerator. The frequency converting control method comprises the steps that the operation frequency of a compressor is acquired; whether the operation frequency of the compressor is larger than the preset threshold value or not is judged; and if yes, the operation frequency of the compressor is controlled in a second frequency converting control mode, and if not, the operation frequency of the compressor is controlled in a first frequency converting control mode. The first frequency converting control mode is a control mode for reducing energy consumption, and the second frequency converting control mode is a control mode for reducing noise. According to the frequency converting control method, the different frequency converting control modes are adopted according to the different operation frequencies of the compressor, accordingly, energy consumption or noise within the refrigerator operation period is reduced according to the need as far as possible, the loss of the refrigerator during low-frequency stable operating is small, and the overall energy efficiency of the refrigerator is good; and meanwhile, the noise is lowered when the refrigerator operates at the high frequency under the condition that the demand for the refrigerating capacity is large, and the noise situation of the refrigerator is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

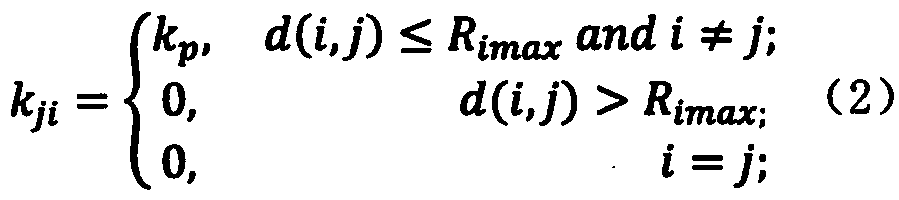

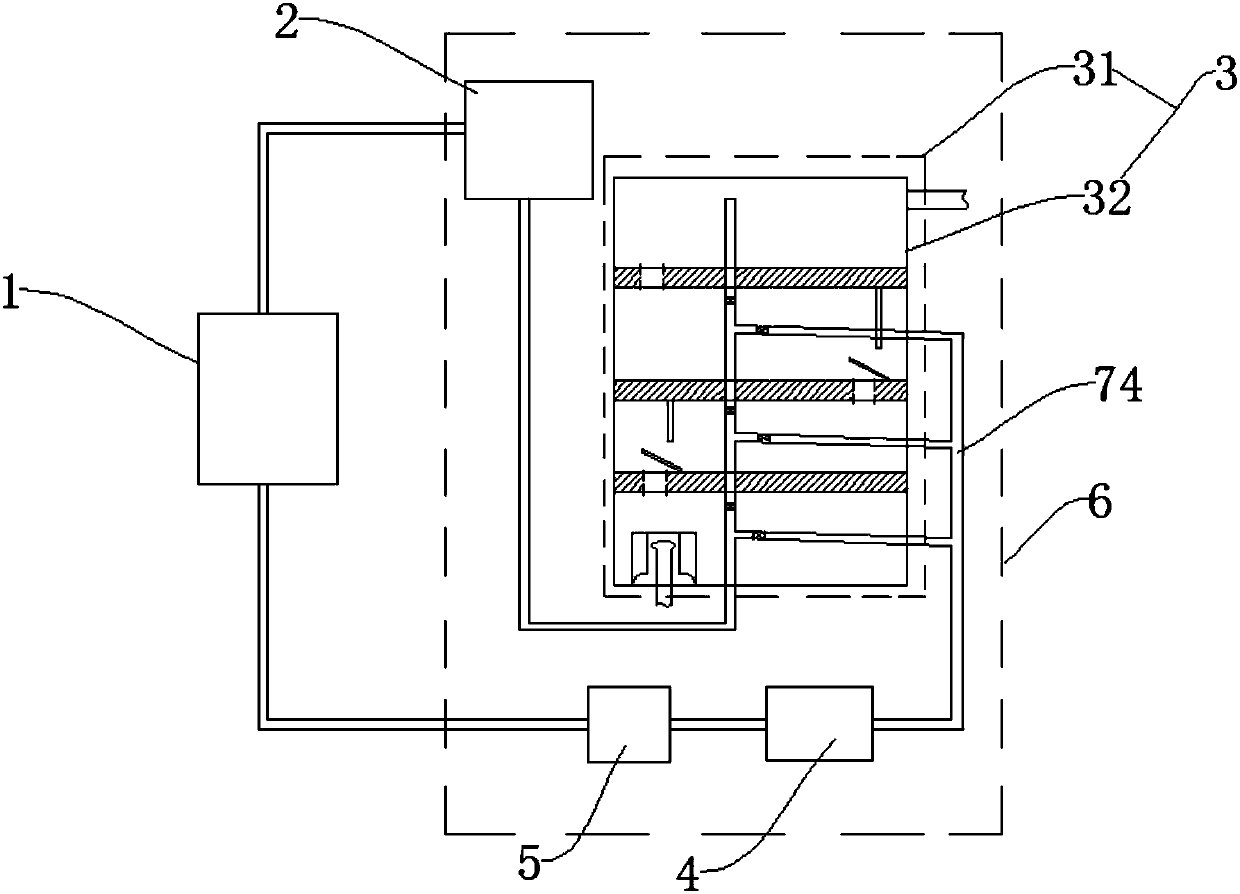

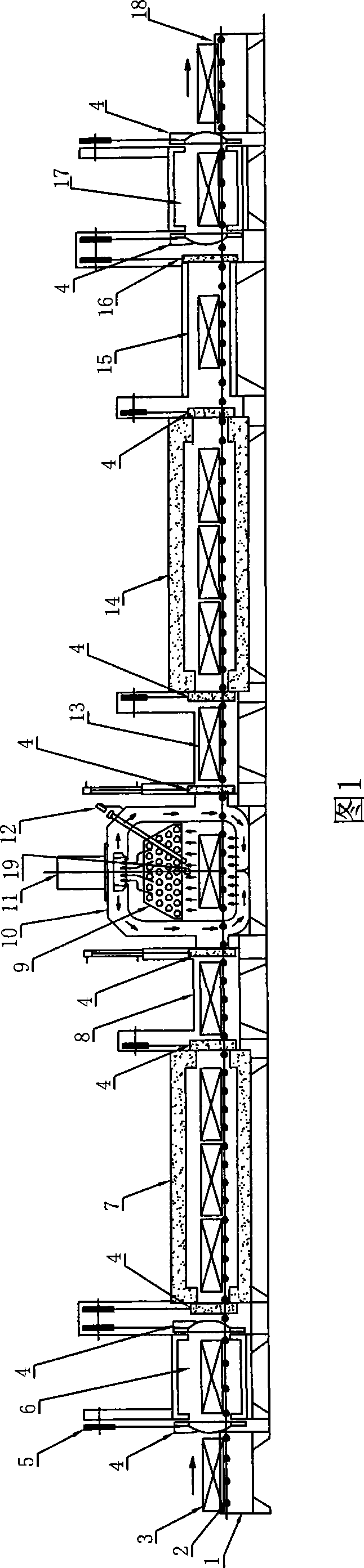

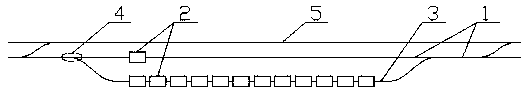

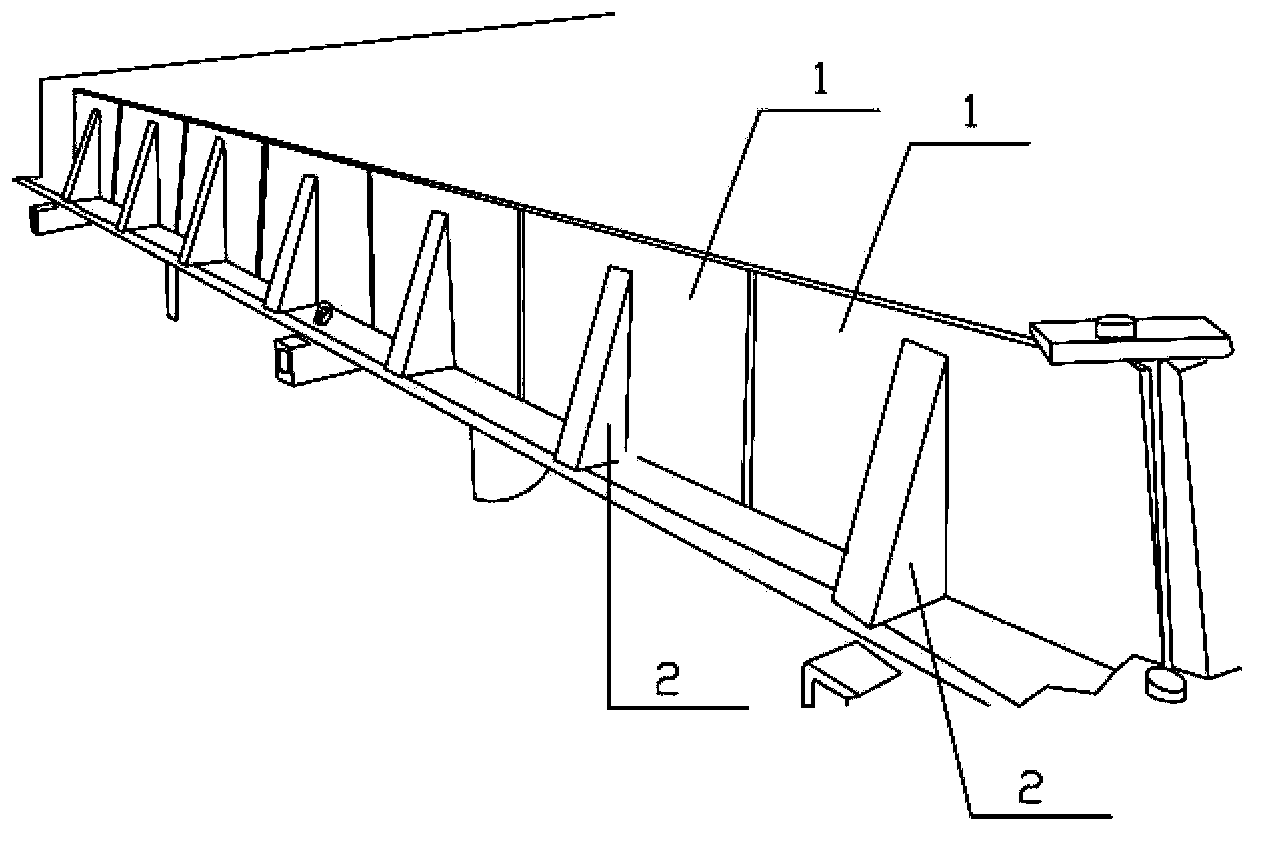

Point-to-point unmanned transportation system and use method thereof

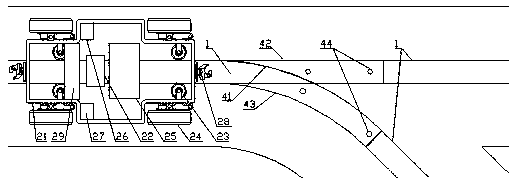

PendingCN109774731AImprove fluencyImprove operational efficiencyAutomatic systemsElectric locomotivesTransit systemAutomotive engineering

The invention discloses a point-to-point unmanned transportation system and a use method thereof. The system comprises more than one platform, wherein the platforms are connected through a traveling track (1), and electric cars (2) capable of reaching each platform along the traveling track (1) are connected to the traveling track (1); each platform comprises a parking track (3) capable of sequentially parking more than one electric car (2), and the parking tracks (3) are connected with the traveling track (1) through reversing mechanisms (4); the parts, on branch roads, of the traveling rail(1) are also connected through the reversing mechanisms (4). The system has the advantages of being high in operation efficiency, low in cost, high in flexibility, economical, capable of saving energyand convenient to use.

Owner:贵州凯因泰科技有限公司

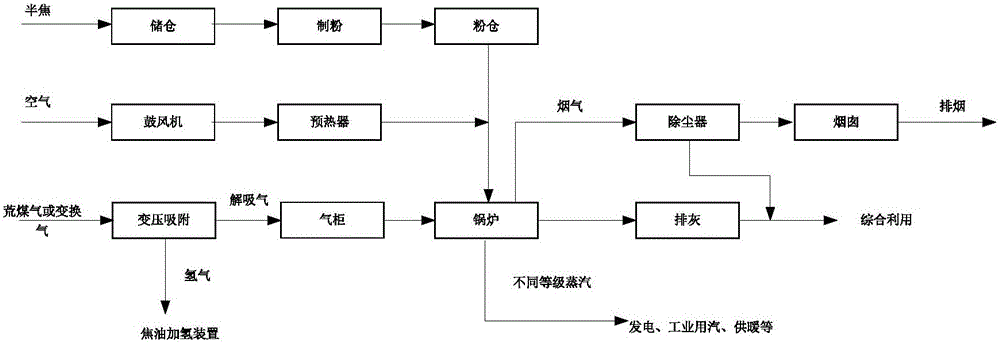

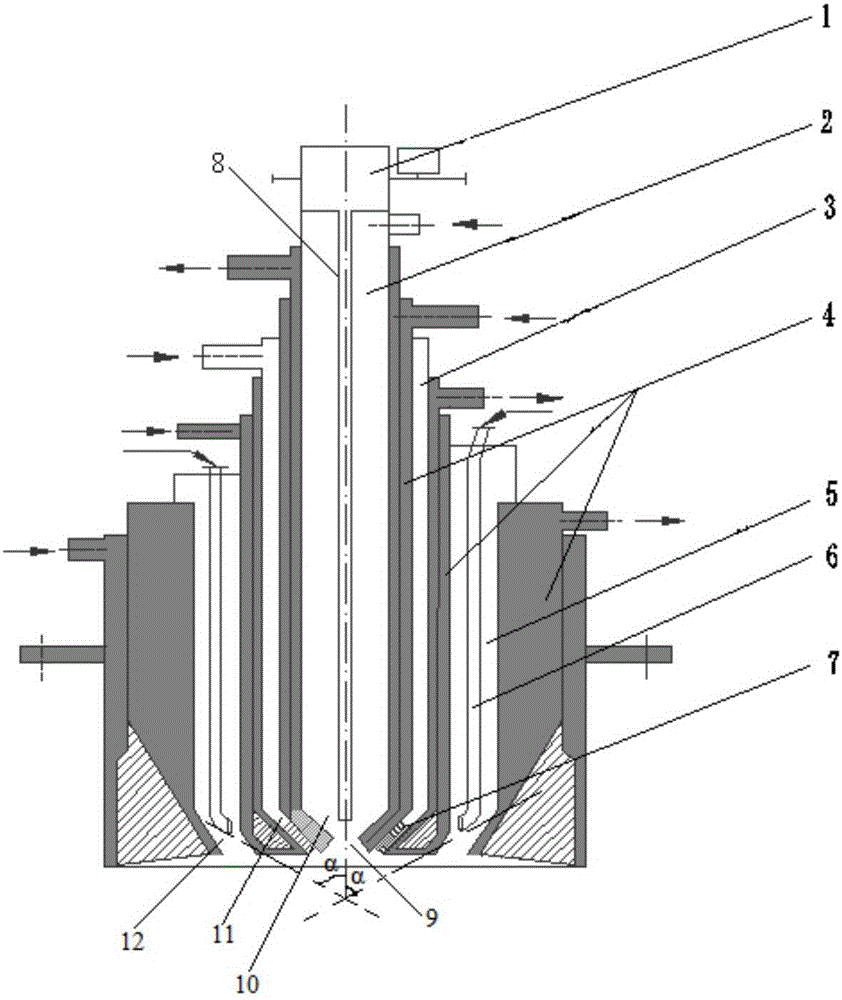

Method for co-combusting dry-distilled crude gas or hydrogen production desorption gas thereof and semicoke

InactiveCN105820843AIncrease the blending ratioAchieving mass utilizationEnergy inputGasification processes detailsFlue gasDesorption

The invention discloses a method for co-combusting dry-distilled crude gas or hydrogen production desorption gas thereof and semicoke. The method comprises the following steps: S1, grinding semicoke into powder, and jetting the coke powder to a combustion device through a coke powder channel in a burner by taking air, fuel gas or nitrogen as a conveying medium; S2, pressurizing and heating air, and then jetting the air to the combustion device through a gasifier channel in the burner; S3, jetting the dry-distilled crude gas or the hydrogen production desorption gas thereof into the combustion device through a combustible gas channel in the burner to fully mix the gas with the coke powder obtained in the step S1 and the air from the step S2 for combustion, and preheating the air in the step S2 with flue gas produced in a combustion process to increase the temperature to make the coke powder combusted fully. A test shows that the ringelman emittance in the flue gas is of the first level, which shows that the combustion is full.

Owner:HUADIAN HEAVY IND CO LTD

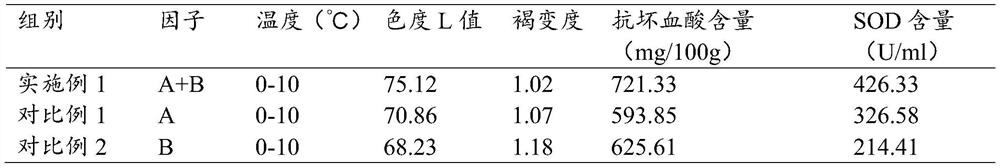

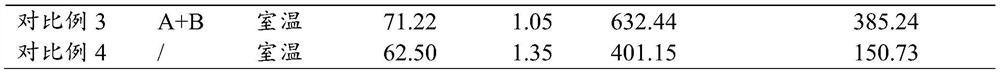

Hippophae rhamnoides whole fruit powder preparation method capable of reducing caking rate and loss rate of bioactive substances

PendingCN113966816AHigh retention rateGood value for moneyFood freezingFood preservationFreeze-dryingHippophae rhamnoides fruit

The invention relates to the technical field of hippophae rhamnoides fruit powder preparation, in particular to a hippophae rhamnoides whole fruit powder preparation method capable of reducing the caking rate and the loss rate of bioactive substances. The preparation method comprises the following steps: pre-freezing hippophae rhamnoides fruits, taking liquid carbon dioxide as a refrigerant, synchronously dropwise adding a compound protective agent of glucose oxidase and ascorbic acid, performing low-temperature deoxygenation pulping and centrifugal separation to obtain hippophae rhamnoides fruit pulp and hippophae rhamnoides fruit residues, performing microwave vacuum freeze drying on the hippophae rhamnoides fruit pulp to prepare hippophae rhamnoides fruit pulp powder, preparing hippophae rhamnoides fruit residue powder from hippophae rhamnoides fruit residues through pre-freezing, ultra-micro cryogenic grinding and microwave vacuum freeze-drying in sequence, then adding the hippophae rhamnoides fruit residue powder and silicon dioxide into hippophae rhamnoides fruit pulp powder, and mixing to obtain the hippophae rhamnoides whole fruit powder. The hippophae rhamnoides fruit powder prepared by adopting the method has the characteristics of high product yield, low caking rate, high bioactive substance retention rate, high drying efficiency and the like.

Owner:XINJIANG AGRI UNIV

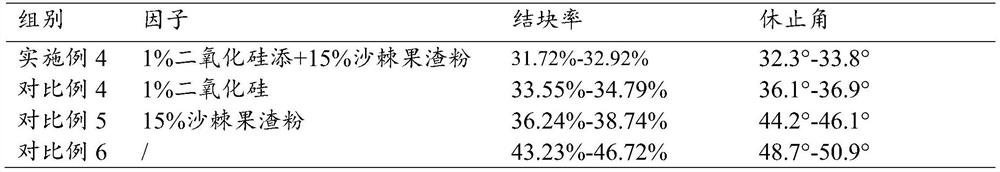

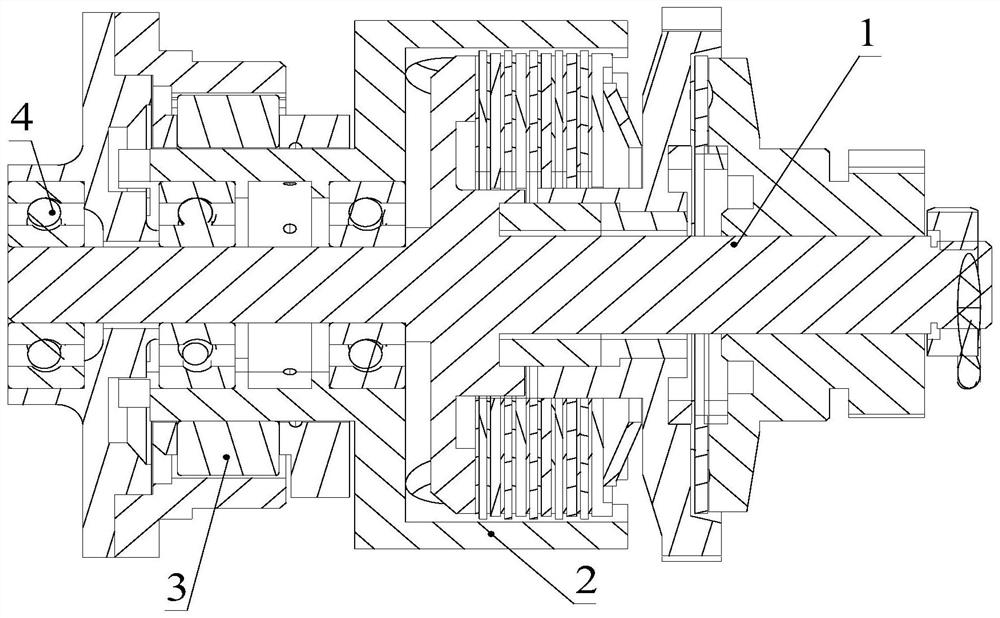

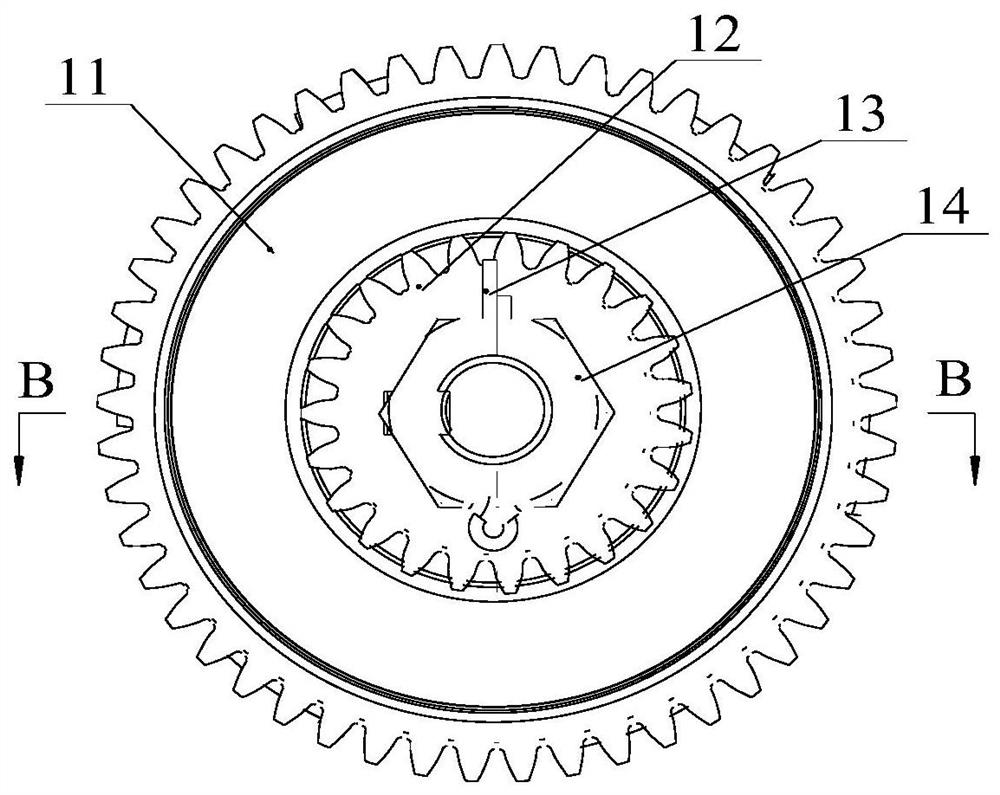

Load-sensitive controllable driving structure

PendingCN113931998AImprove efficiencyReduce ineffective energy consumptionGear lubrication/coolingFriction clutchesEnergy consumptionOne stage

The invention provides a load-sensitive controllable driving structure. The load-sensitive controllable driving structure comprises a friction component, wherein the friction component is coaxially connected with a non-return component in series, the friction component and the non-return component are in transmission through an outer rotating shaft, and the rear end of a spindle in the friction component is rotationally fixed to the rear end of the non-return component through a tail bearing; and two stages of gears are arranged in the non-return component, a friction plate is arranged between transmission structures of the two stages of gears, one stage of gear drives the spindle to rotate, and the other stage of gear is rotationally installed on the spindle. According to the load-sensitive controllable driving structure, load can be converted into self-locking torque, the efficiency of the transmission structures is effectively improved, invalid energy consumption of a system is reduced, and higher loading capacity and lower system power consumption can be obtained under the condition of the same size and weight; and the problems that an existing transmission mechanism with a self-locking structure is low in efficiency, large in power consumption, large in heat emission and short in system service life are solved.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Brilliant isothermal normalizing production system

ActiveCN101363071BReduce ineffective energy consumptionSolve the problem of serious burning loss and oxidationNuclear engineeringCooling chamber

The invention relates to a bright isothermal normalizing production system which comprises a feeding table, a normalizing heating furnace, a sealed fast cooling chamber, an isothermal furnace, a watercooling chamber and a discharge table, wherein, the feeding table, the normalizing heating furnace, the sealed fast cooling chamber, the isothermal furnace, the water cooling chamber and the discharge table are sequentially connected to form a run-through inner cavity inside; a front vacuum chamber is arranged between the feeding table and the normalizing heating furnace, a transition chamber isarranged between the normalizing heating furnace and the sealed fast cooling chamber, a rear transition chamber is arranged between the sealed fast cooling chamber and the isothermal furnace, and a rear vacuum chamber is arranged between the water cooling chamber and the discharge table; sealing doors are respectively arranged at openings at two ends of the normalizing heating furnace, the sealedfast cooling chamber, the isothermal furnace, the front vacuum chamber and the rear vacuum chamber; and a water cooling chamber door is arranged at the end face of the opening of the water cooling chamber close to the rear vacuum chamber. The production system has the beneficial effect of no oxidization of the heat treated products, small hardness scattering difference, saving energy and materials, solving the problems of unstable product quality and severe burning loss and oxidization of steel products. The bright isothermal normalizing realizes the ideal effect of high quality, energy and materials saving, and environmental protection.

Owner:HANGZHOU JINZHOU TECH CO INC

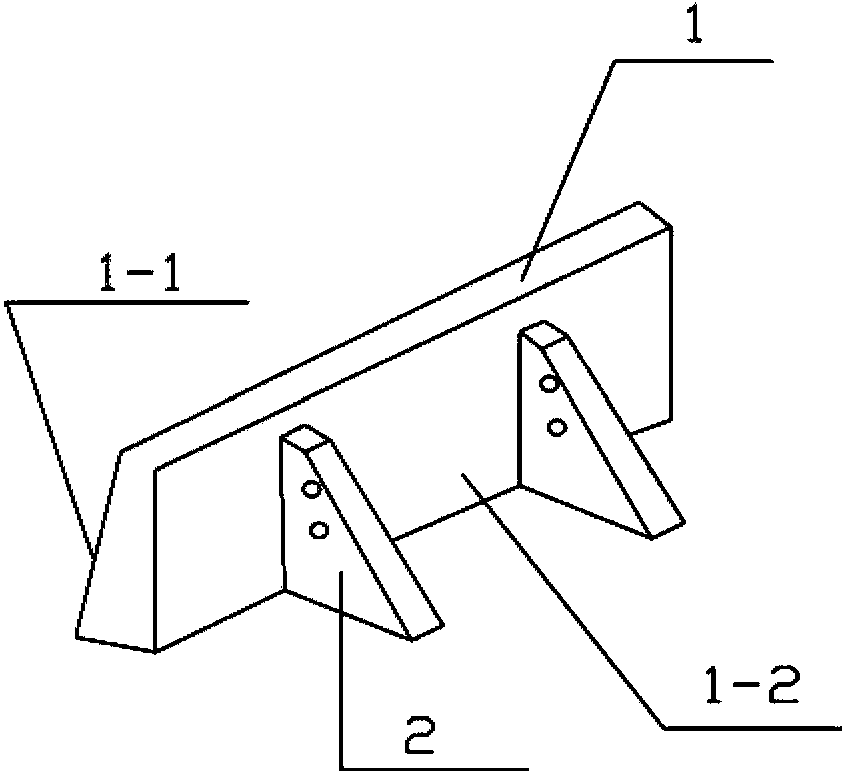

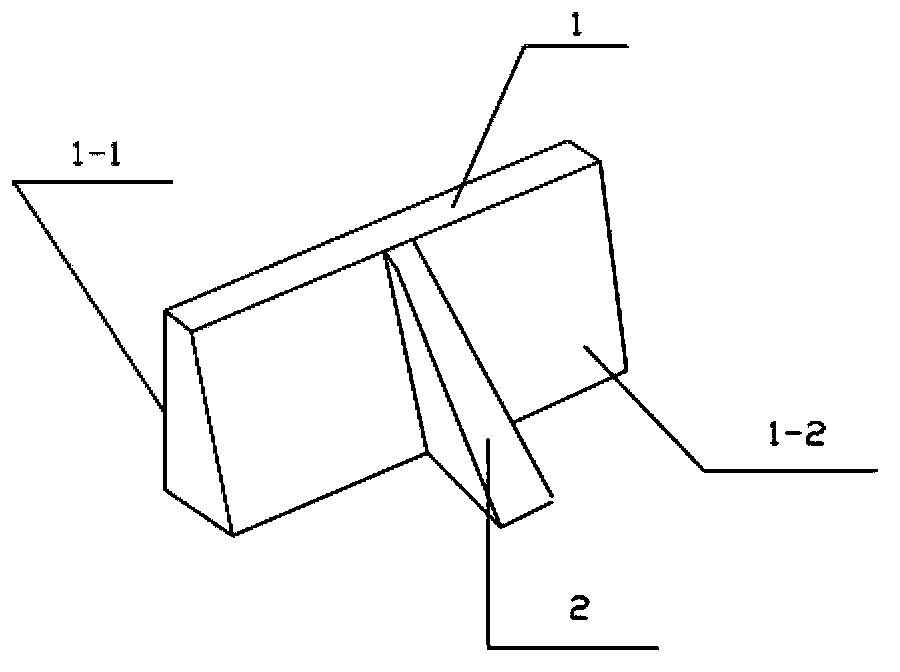

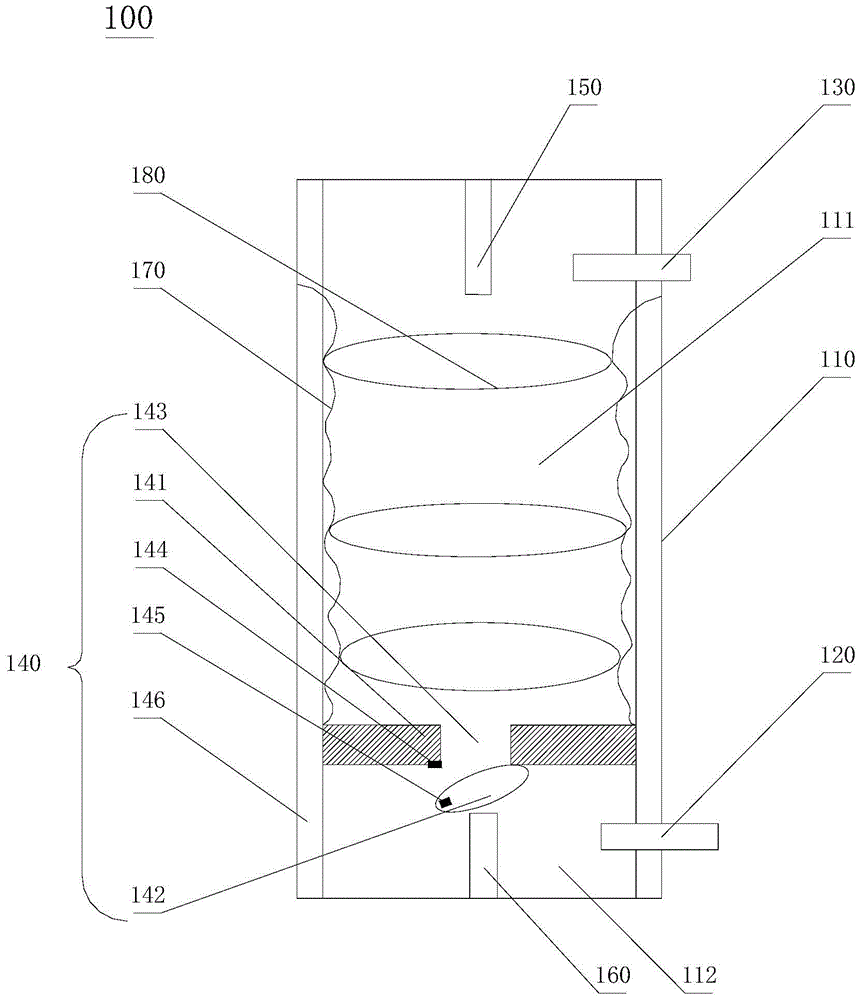

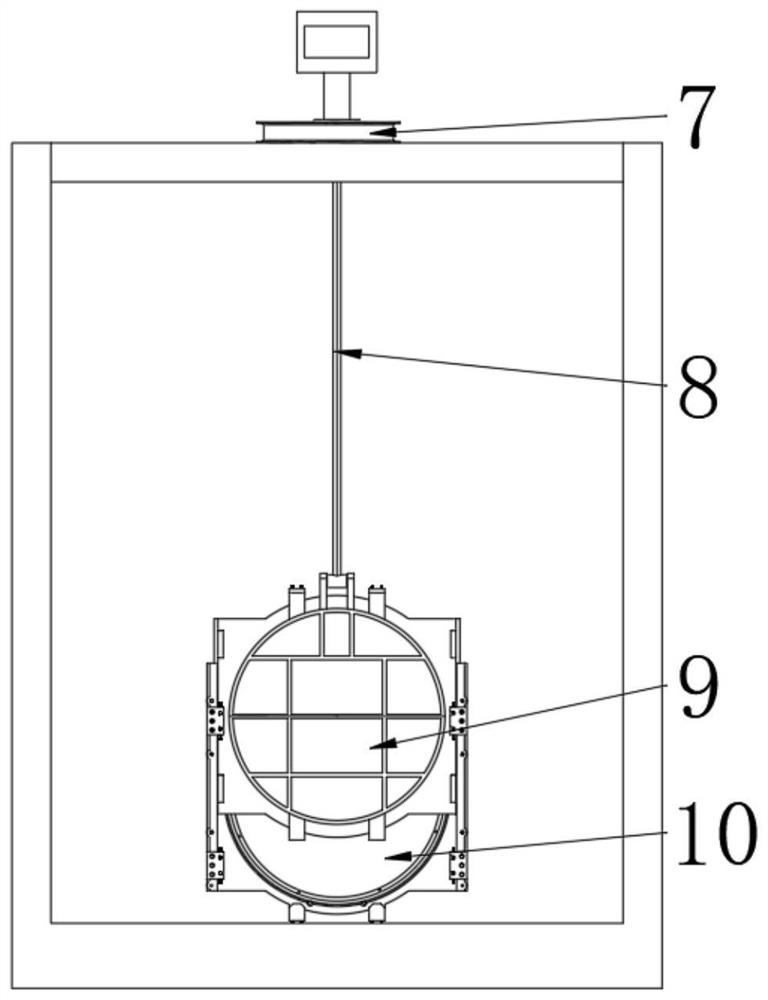

Vertical insulation water tank and air energy water heater

ActiveCN104061682BAvoid hot and cold situationsReduce output rateFluid heatersThermal insulationHolding tank

The invention provides an upright thermal insulation water tank and an air energy water heater. The upright thermal insulation water tank comprises a box body, a cold water inlet, a hot water outlet and a partition plate assembly arranged in the inner cavity of the box body; the partition plate assembly can move in the inner cavity of the water tank up and down; the outer edge of the partition plate is abutted against the side wall of the box body; the partition plate assembly divides the inner cavity of the box body into an upper cavity and a lower cavity; the cold water inlet is formed in the inner wall of the lower cavity; the hot water outlet is formed in the inner wall of the upper cavity. The partition plate assembly is arranged in the water tank of the upright thermal insulation water tank, hot water and cold water are isolated by the partition plate assembly, and replenished cold water is not fully mixed with the hot water, so hot water output rate is prevented from being reduced after the hot water and the cold water are mixed; ineffective energy consumption is reduced by the arrangement, the energy saving effect is improved, and the energy is saved by about 15% compared with that of the existing water tank.

Owner:GREE ELECTRIC APPLIANCES INC

Domestic fungus strip processing method

InactiveCN109549179AEnergy-saving and efficient blanchingEnergy efficient blanching methodFood scienceFlammulinaHorticulture

The invention discloses a domestic fungus strip processing method. The domestic fungus strip processing method comprises following steps: 1, pleurotus eryngii stipe, flammulina velutipes root, and lentinus edodes stipe are washed for further processing; 2, the processed pleurotus eryngii stipe, flammulina velutipes root, and lentinus edodes stipe are subjected to boiling in clear water at 100 to 120 DEG C for 40 to 60min; and 3, the boiled pleurotus eryngii stipe, flammulina velutipes root, and lentinus edodes stipe are chopped and smashed so as to obtain pleurotus eryngii paste, flammulina velutipes paste, and lentinus edodes paste for further processing; and 4, 80 to 100g of pleurotus eryngii paste, 80 to 100g of flammulina velutipes paste,80 to 100g of lentinus edodes paste, 50 to 60g of table salt, and 80 to 100g of spices are mixed so as to obtain a mixture. The domestic fungus strip processing method is capable of realizing value adding processing utilization of by products suchas domestic fungus stipe.

Owner:四川万良食品科技有限公司

A graded storage injection molding machine

The invention provides a graded storage injection molding machine. The injection molding machine comprises a barrel capable of plasticizing the materials, a molten material tube, a storage cylinder capable of storing the material in a grading manner, and an injection cylinder, wherein plungers are flexibly sleeved in the storage cylinder and the injection cylinder respectively and connected with an oil cylinder, and the molten material tube is respectively and sequentially communicated with a discharge end of the barrel, the storage cylinder and the injection cylinder from the top to the bottom; a three-way change-over valve is arranged on the connection part of the molten material tube and the injection cylinder, and the injection cylinder is connected with a spray nozzle by the three-way change-over valve. The molten material which is plasticized by the barrel is stored in the storage cylinder and the injection cylinder in a grading manner, so that the plasticizing performance and the exhaust performance of the material are reliably ensured, and the quality of the materials is stable; simultaneously the barrel can continuously provide the molten material, and the plasticizing process of the materials and the quick filling of the storage cylinder with the molten material can be simultaneously performed in the machine injection pressure retaining period, so as to prepare for injection of the molten material in the next period. The graded storage injection molding machine is high-efficient and energy-saving and low in failure rate.

Owner:广东福能精密机械有限公司

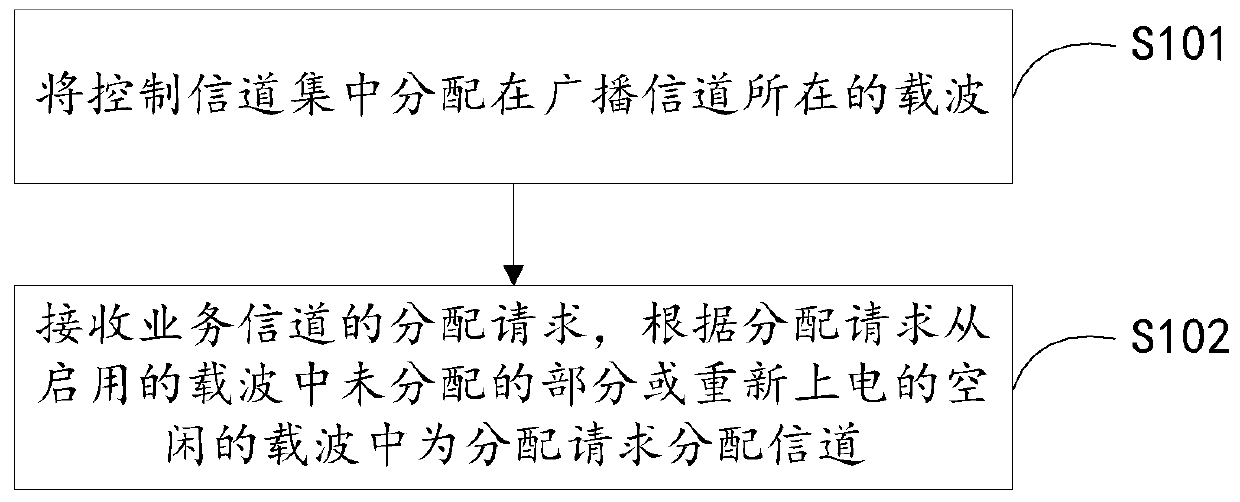

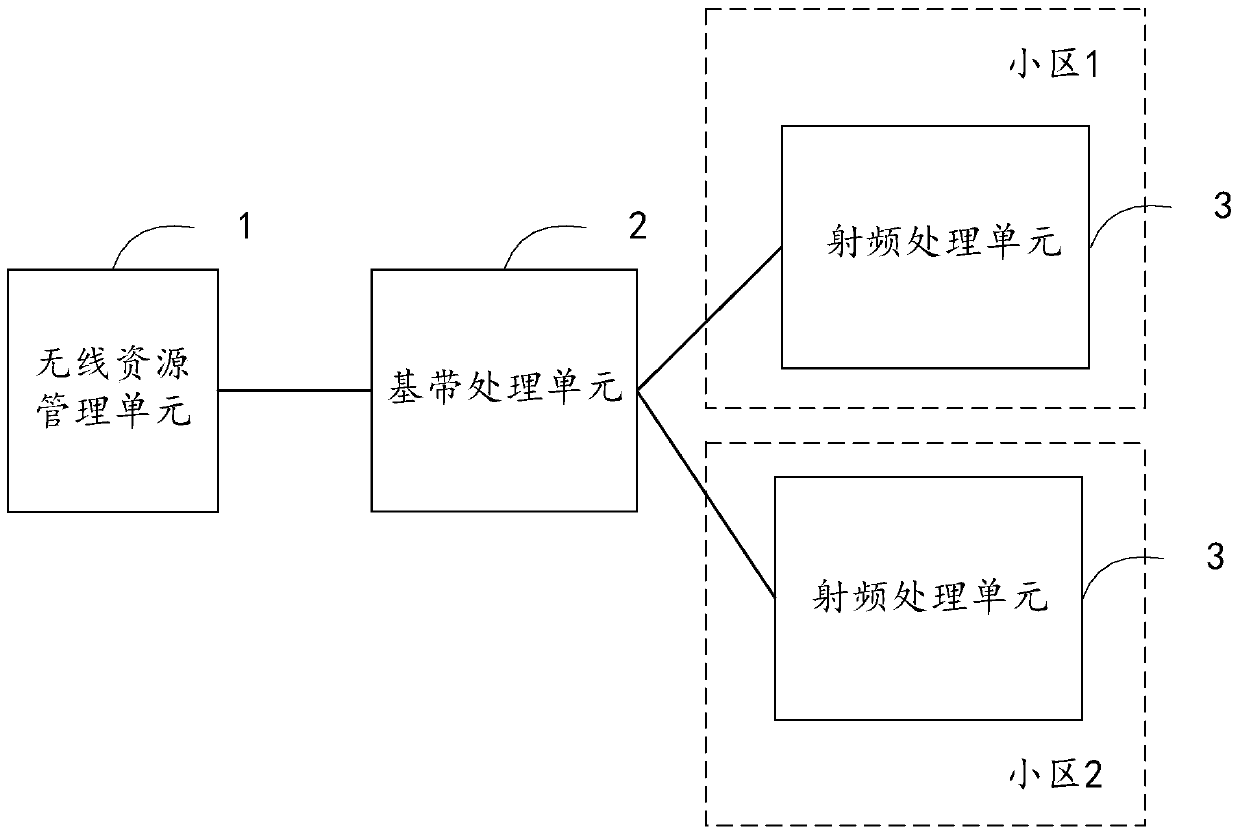

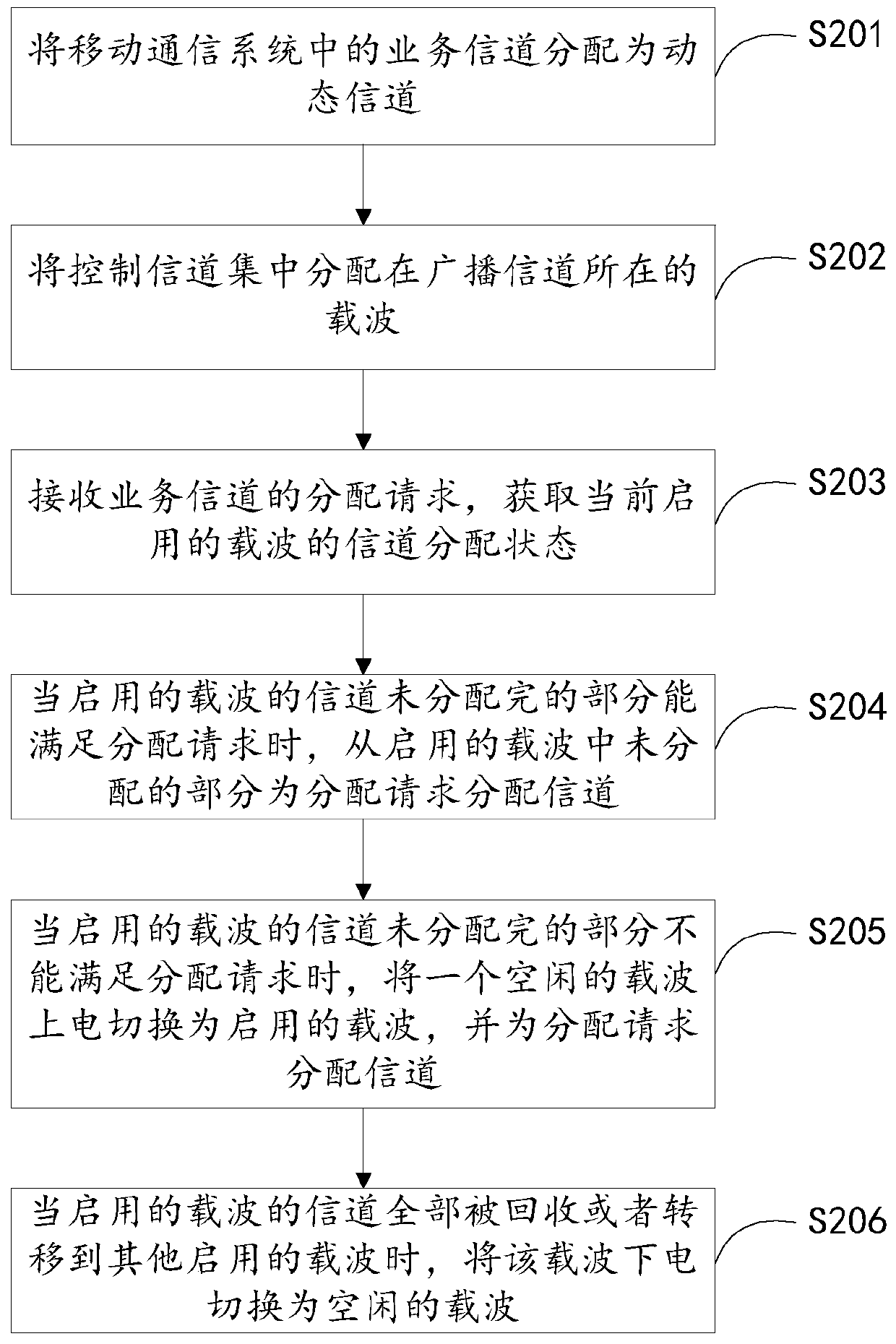

A channel allocation method and system

ActiveCN107277863BImprove utilization efficiencySignificant power saving effectPower managementNetwork traffic/resource managementElectricityCarrier signal

Owner:ZTE CORP

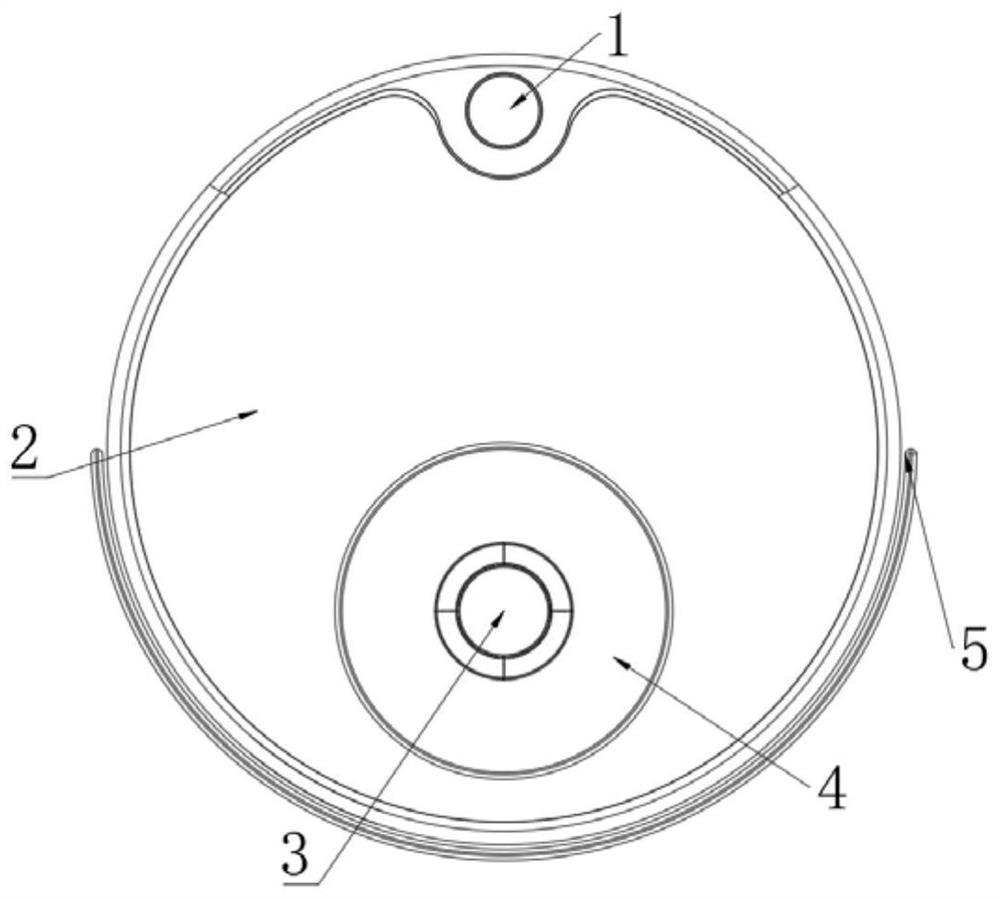

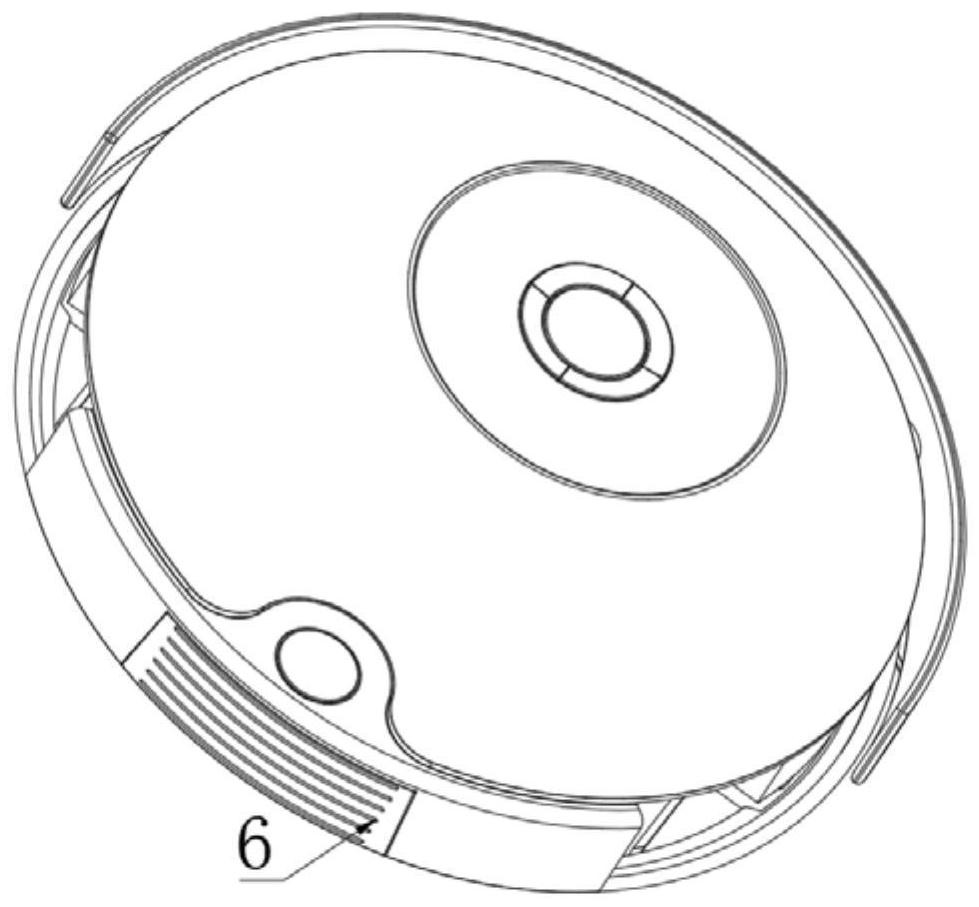

Control system for blue-green algae fishing robot and control method thereof

ActiveCN114855737AImprove cleaning efficiencyEasy inflowWater cleaningEnergy based wastewater treatmentControl systemEngineering

The invention discloses a control system for a blue-green algae salvage robot and a control method thereof, and belongs to the technical field of blue-green algae salvage. When the robot works in the cleaning area, a blue-green algae mixture enters the robot through the feeding port to complete the collecting action, in order to improve the cleaning efficiency of the robot, when the blue-green algae mixture is collected, the air exhaust mechanism is started to assist in collecting the blue-green algae mixture, and the blue-green algae mixture flowing into the robot flows inwards through the flow inlet channel; a plurality of permeation holes are formed in the tail part of the inflow channel, water in the blue-green algae mixture flows into the drainage area through the permeation holes, and the blue-green algae solid enters the packaging box, so that simple dry-wet separation is realized; the opening and closing mechanism is installed in the shell, the rhizomes of the blue-green algae can be cut off, and the situation that clamping stagnation affects the follow-up blue-green algae collection action is prevented.

Owner:NANJING XIAOZHUANG UNIV

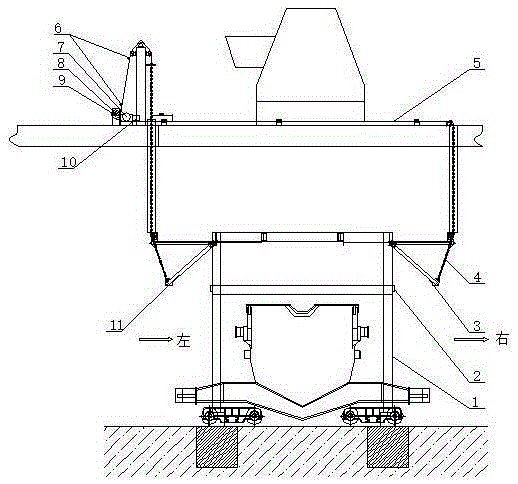

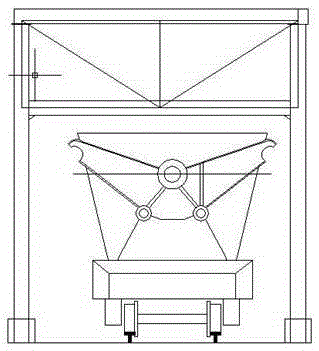

The method of retracting and retracting the high temperature dust collection baffle

ActiveCN104152619BOvercome the disadvantage of not working properlyImprove dust collection efficiencyDust arrestersCold airFlue gas

The invention relates to a method for folding and unfolding a high-temperature dust-collecting baffle plate. A high-temperature dust-collecting hood device is installed in a position of a smelting blast furnace where molten iron is poured to a hot-metal bottle; the high-temperature dust-collecting hood device comprises a high-temperature dust-collecting baffle plate device, a high-temperature dust-collecting baffle plate folding and unfolding device and the like; the high-temperature dust-collecting baffle plate folding and unfolding device consist of a motor, a speed reducer, a band-type brake device, a resisting device, a coiling device, a pulley, a steel rope, a high-temperature chain, a high-temperature dust-collecting baffle plate, a manual winding device, a dust-collecting hood, a dust-collecting fan and the like. According to the method provided by the invention, the dust-collecting efficiency of the dust-collecting hood is improved, suction of cold air or clean air is reduced, and the ineffective energy consumption is reduced. At the same time, the effective capture amount of dust-containing flue gas is increased and pollutions to operating post and ambient environment are reduced. The method can be widely applied to the technical field of environmental protection.

Owner:YUNNAN HUAYUN TIANLANG ENVIRONMENTAL PROTECTION

Multistage distributed water pump heat supply system and design method thereof

InactiveCN102944034BExcellent hydraulic stabilityReduce transportation energy consumptionLighting and heating apparatusHot-water central heatingConnection typeFrequency conversion

A multistage distributed water pump heat supply system and a design method thereof relate to a heat supply system and the design method thereof. The system and the method aim at resolving the problem that a traditional direct connection type central heating system is large in ineffective energy consumption, hydraulic power work conditions are mutually coupled, hydraulic power work conditions of a distributed frequency conversion water pump system are coupled and cannot meet the requirement for system extension or load change, balance of hydraulic power of heat users before zero-pressure different point is damaged, and the existing heat supply system adopting a voltage sharing tank is large in ineffective energy consumption and large in voltage sharing tank diameter. The multistage distributed water pump heat supply system comprises a heat source, a heat source position circulation water pump unit, a water supply pipe, a water return pipe and a multistage distribution station. Each-stage distribution station comprises a decoupling tube, a classification pressurization pump and at least one secondary net loop. Each secondary net loop is composed of a heat user pressurization pump and at least one heat user. Decoupling pipes of the multi-stage distribution station are arranged in parallel. The multistage distributed water pump heat supply system is used for centralized heat supply.

Owner:HARBIN INST OF TECH +1

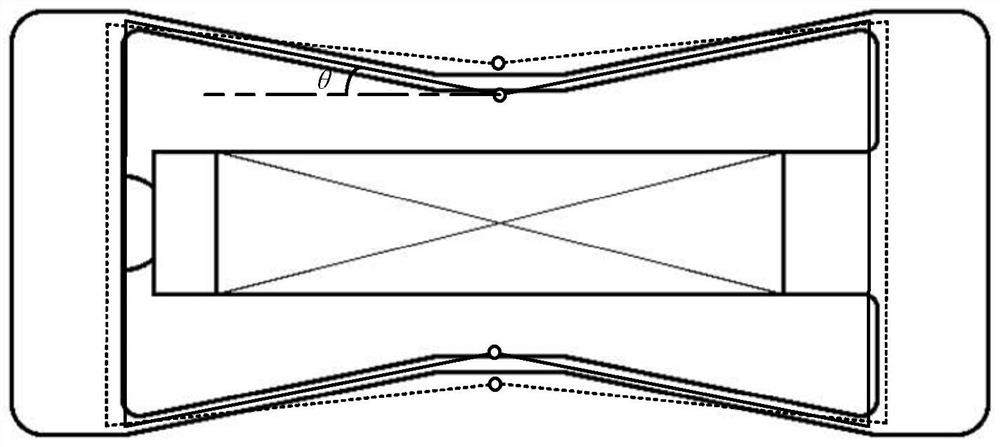

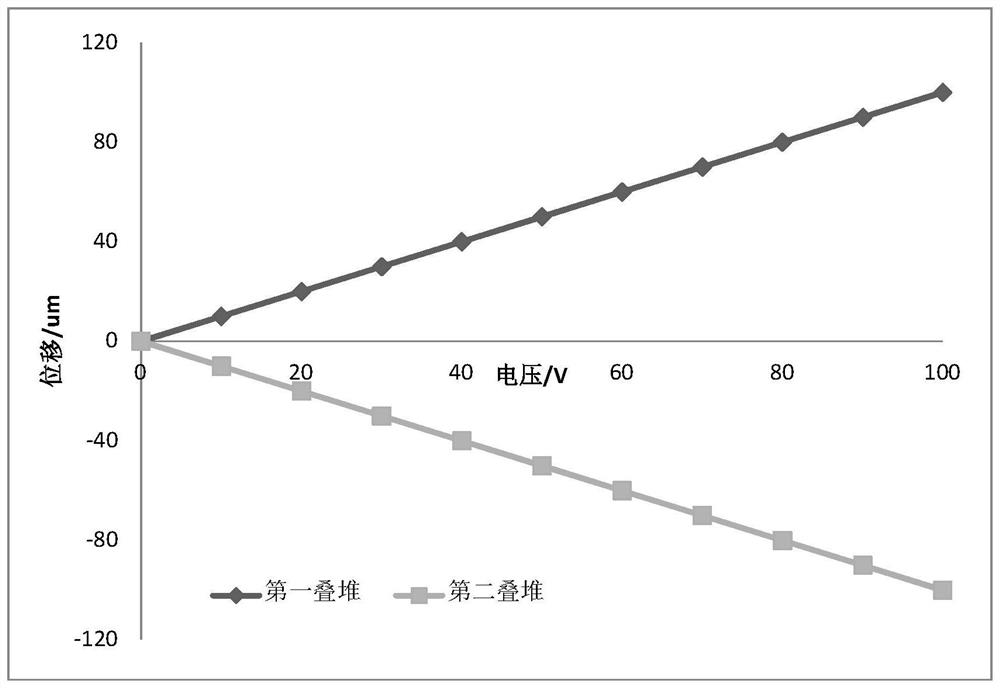

An optical image stabilization device and its control system based on piezoelectric stack

ActiveCN112817161BSolve mutual couplingReduce ineffective energy consumptionProgramme controlPrintersLoop controlControl system

The invention discloses an optical image stabilization device based on piezoelectric stacking, comprising a lens mounting bracket, the lens mounting bracket is located in the displacement amplifying direction of a first displacement amplifying module, and is connected to the first displacement amplifying module through a connecting block. In the first rectangular frame; the first rectangular frame is located in the displacement amplifying direction of the second displacement amplifying module, and the second displacement amplifying module is connected by a connecting block, and the whole is arranged in the second rectangular frame; the first and second displacement amplifying modules The modules are arranged in parallel, and the two extend under the action of the applied voltage, respectively producing positive and negative displacement outputs acting on the lens mount. The displacement amplifying module of the present invention decouples the displacement in the forward and reverse directions, so that the piezoelectric stack does not need a pre-voltage to maintain a certain pre-displacement in the initial stage. A closed-loop control system is also designed in the present invention, the displacement index is tested by the built-in displacement sensor of the image stabilization device, and the central processing unit module calculates and performs high-precision displacement control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

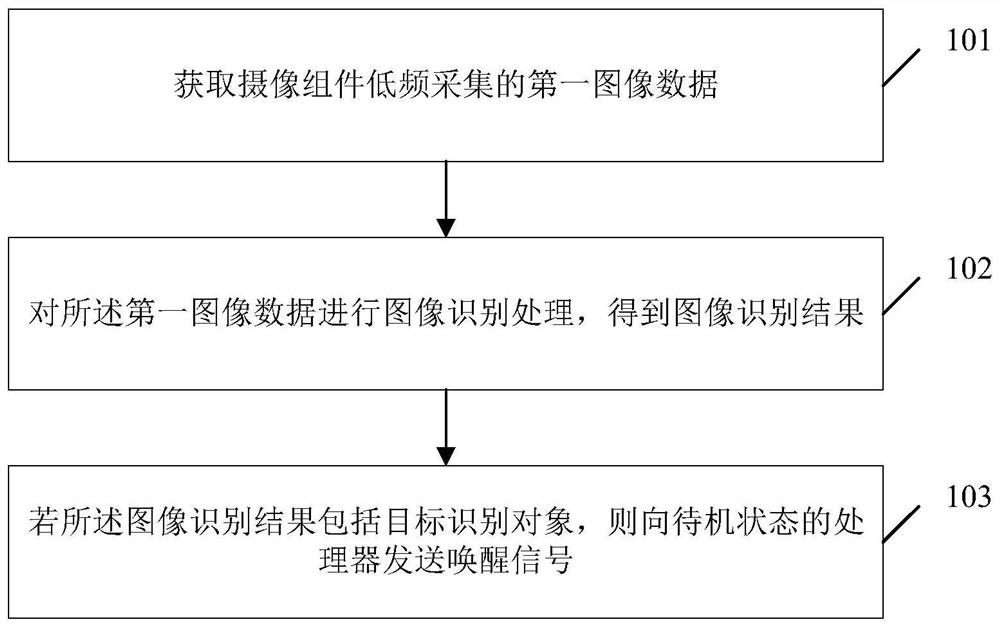

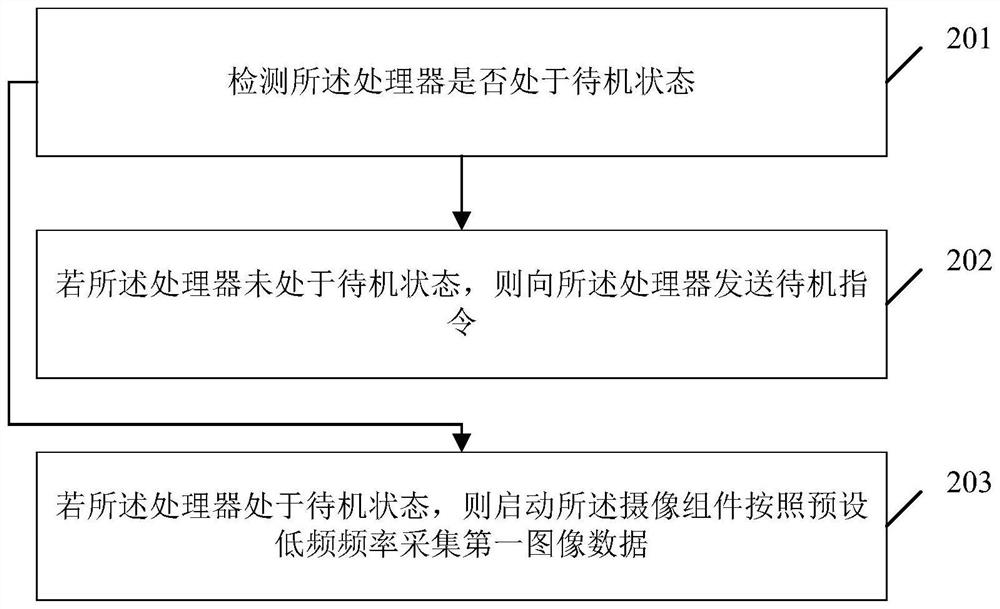

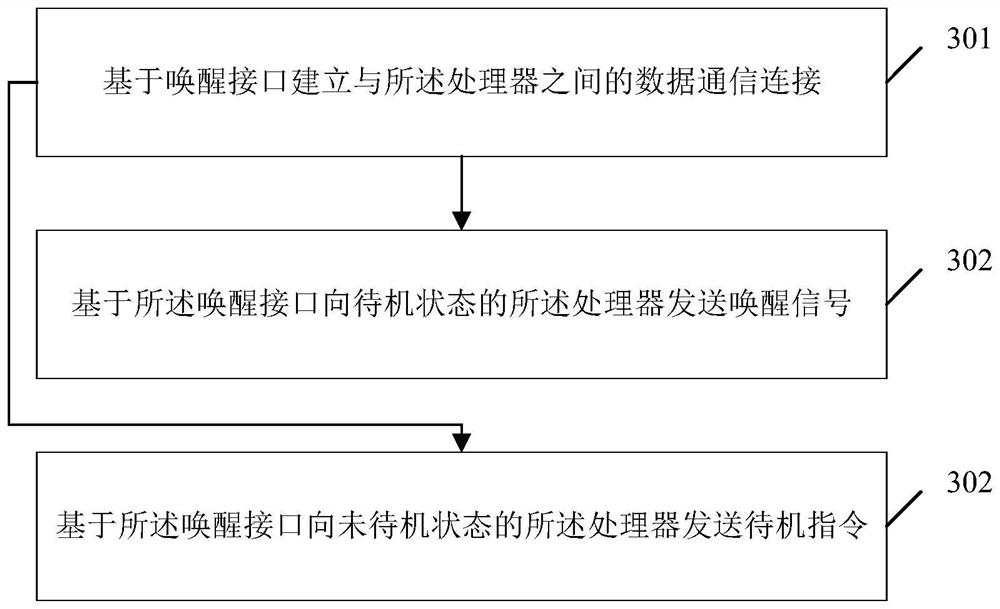

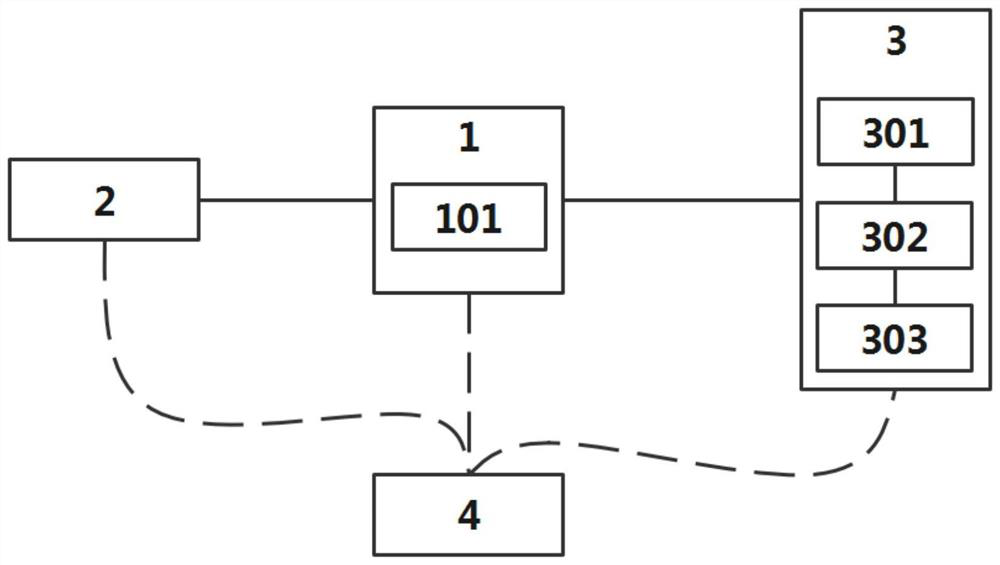

Processor awakening method, device and system, storage medium and AR glasses

PendingCN114785954AReduce ineffective energy consumptionReduce energy consumptionTelevision system detailsColor television detailsComputer hardwareEyeTap

The embodiment of the invention discloses a processor awakening method, device and system, a storage medium and AR glasses, relates to the technical field of AR, and is used for solving the problem of high power consumption caused by continuous data processing of a processor in the prior art. The method mainly comprises the following steps: acquiring first image data acquired by a camera component at low frequency; performing image recognition processing on the first image data to obtain an image recognition result; and if the image recognition result comprises a target recognition object, sending a wake-up signal to a processor in a standby state so as to drive the processor to perform image processing based on second image data acquired by the camera component at high frequency.

Owner:シェンジェンインムーテクノロジーシーオーエルティーディー

Energy-saving cell rapid screening method

PendingCN113891415AReduce ineffective energy consumptionPower managementHigh level techniquesUser equipmentEnergy consumption

The invention relates to an energy-saving cell rapid screening system, and the system comprises at least one cell and user equipment; the system can perform modeling prediction on historical service load data of each cell based on intelligent calculation, and under the limitation of dormancy wake-up frequency and / or cell value grading, judge the predicted daily service load capacity through a low-load time window, and determine at least one energy-saving cell and a daily energy-saving strategy thereof, so that the energy-saving cell can trigger user equipment in the cell to carry out load migration to an adjacent cell in an energy-saving time period, and the energy-saving cell can be converted to a low-energy-consumption dormant state after load migration. Through the system, the energy-saving time period can be dynamically and flexibly selected, the range of the energy-saving base station is expanded, and the purpose of low-cost network energy saving can be achieved without depending on additional arrangement of hardware equipment. According to the system, the switching state of the base station does not need to be frequently switched, and the effect of reducing the energy consumption of the system can be achieved while the complexity is lower.

Owner:西藏先锋绿能环保科技股份有限公司

Distributed water mixing and pressurized heat supply system having decoupling function and design method of system

InactiveCN102966991BExcellent hydraulic stabilityReduce transportation energy consumptionLighting and heating apparatusSpace heating and ventilation detailsCouplingDifferential pressure

Owner:HARBIN INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com