Hippophae rhamnoides whole fruit powder preparation method capable of reducing caking rate and loss rate of bioactive substances

A bioactive substance and loss rate technology, applied in food science, grain processing, food preservation, etc., can solve problems such as the decline in nutritional value and sensory quality of fruit powder, poor fluidity of powder products, easy moisture absorption and caking quality, etc. , to achieve the effect of high cost performance, reduce caking rate and improve storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

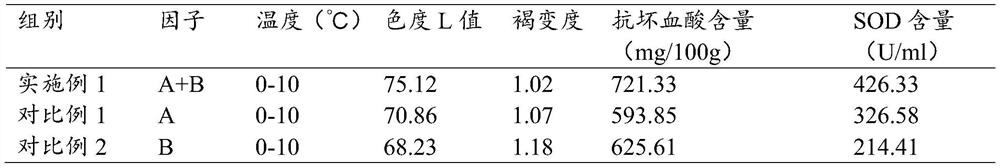

[0034] Put the seabuckthorn fruit into the beater, and simultaneously dropwise add 1.5% of the mass of the seabuckthorn fruit with an aqueous solution containing 0.4g / L glucose oxidase or 3.0g / L ascorbic acid, or simultaneously dropwise add 1.5% of the mass of the seabuckthorn The aqueous solution containing 0.4g / L glucose oxidase and 3.0g / L ascorbic acid is compared with the traditional beating at room temperature, adjust the input of liquid carbon dioxide and reduce the ambient temperature to 0-10°C, beat for 1min, take the pulp, and pass through 3000r / min Centrifuge for 1 min to remove the pomace (skin, pomace, seeds) to obtain the puree, and test the relevant indicators.

[0035] Comparative Examples 1-4 are basically the same as Example 1, except that individual factors are different, wherein the aqueous solution of 0.4g / L glucose oxidase is denoted as A, and the aqueous solution of 3.0g / L ascorbic acid is denoted as B, containing 0.4g / L glucose oxidase and 3.0g / L ascorbi...

Embodiment 2

[0041] The eutectic point of the pulp prepared in Example 1 was measured by the electrical resistance method to be -25° C., the pre-freezing temperature was 0-5° C. below the eutectic point, and the typical pre-freezing time was 1.5-2.0 h. Vacuum freezing is adopted, and the thickness of the material is 4mm. At this time, the drying rate is the best, and the moisture content is 60%. After process optimization, the microwave power is finally adjusted to 6kW, the pressure of the drying chamber is 100Pa, and the drying temperature is maintained at 60-65°C. When the central temperature is lower than the lower limit temperature, the microwave switch is turned on, and when the central temperature is higher than the upper limit temperature, the microwave switch is turned off. Seabuckthorn fruit The final water content of the starch powder is 6%. After analysis, under the optimized conditions, the content of vitamin C in seabuckthorn pulp powder is 376.29mg / 100g, the content of flavon...

Embodiment 3

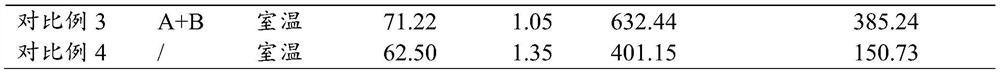

[0043]Spread the pomace obtained in Example 1 to a thickness of 6mm in the material tray, pre-freeze to -18°C, and the typical pre-freezing time is 0.8h; -90°C, the feeding frequency is 15Hz; the crushed pomace is sent to a microwave vacuum freeze dryer, the working parameters are microwave power 6kW, drying temperature 60°C, drying time 6h, drying chamber pressure 100Pa, and the medium Seabuckthorn pomace powder with a particle size of about 40 μm. After analysis, the vitamin C content of seabuckthorn pomace powder is about 3.46mg / 100g, the flavonoid content is 5.231mg / g, and the color, swelling and water solubility are all significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com