Method for co-combusting dry-distilled crude gas or hydrogen production desorption gas thereof and semicoke

A technology of raw coal gas and dry distillation, which is applied in gasification process, manufacture of combustible gas, granular/powdered fuel gasification, etc. It can solve the problem of inability to fix carbon and volatile matter, high residual carbon content in ash residue, semi-coke volatile matter, etc. Low-level problems, to achieve large-scale utilization, reduce equipment costs, and reduce operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

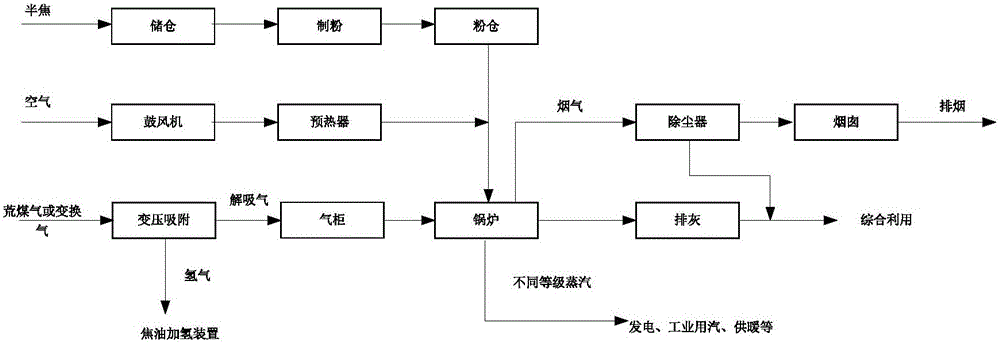

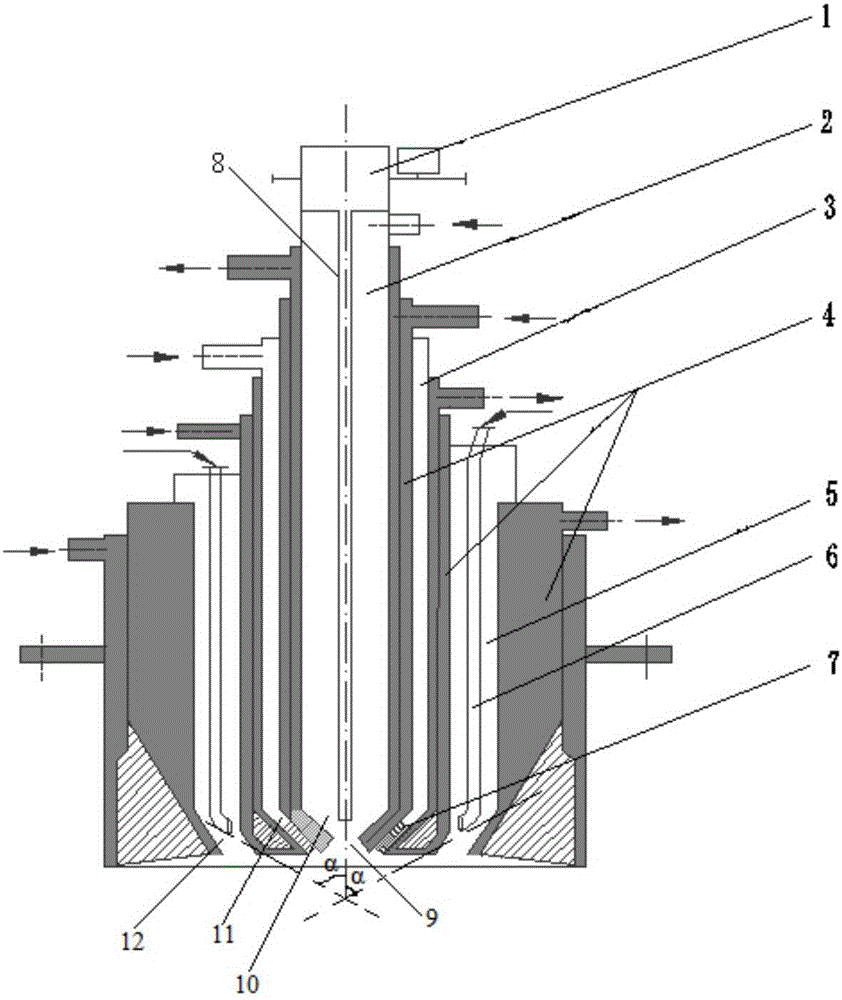

[0047] Such as figure 1 and figure 2 As shown, the dry distillation of raw coal gas or its combined combustion method for hydrogen production, desorption gas and semi-coke provided in this embodiment includes the following steps:

[0048] S1. The semi-coke produced by dry distillation is sent from the coke field by the belt conveyor, through the electromagnet and the crusher to the storage bin in the coal bunker, and then enters the coal mill through the feeder for grinding and pulverization, and passes through the air (Generally, the temperature is controlled below 70°C) and sent to the screening device to obtain powder coke with a particle size of 10 μm, which is stored in the powder bin for later use. The powder coke in the powder bin is sent from the powder feeder to the burner, and passed The coke powder channel 5 in the mouth is sprayed into the boiler;

[0049] S2. After the air is boosted by the blower, it enters the air preheater, absorbs the heat in the flue gas a...

Embodiment 2

[0060] Such as figure 1 and figure 2 As shown, the dry distillation of raw coal gas or its combined combustion method for hydrogen production, desorption gas and semi-coke provided in this embodiment includes the following steps:

[0061] S1. The semi-coke produced by dry distillation is sent from the coke field by the belt conveyor, through the electromagnet and the crusher to the storage bin in the coal bunker, and then enters the coal mill through the feeder for grinding and pulverization, and is passed through nitrogen Send it to the screening device to obtain powder coke with a particle size of 100 μm, store it in the powder bin for later use, send the powder coke in the powder bin to the burner from the powder feeder, and spray it to the boiler through the powder coke channel 5 in the burner Inside;

[0062] S2. After the air is boosted by the blower, it enters the air preheater, absorbs the heat in the flue gas, and the temperature rises. Finally, the air is boosted ...

Embodiment 3

[0073] Such as figure 1 and figure 2 As shown, the dry distillation of raw coal gas or its combined combustion method for hydrogen production, desorption gas and semi-coke provided in this embodiment includes the following steps:

[0074] S1. The semi-coke produced by dry distillation is sent from the coke field by the belt conveyor, through the electromagnet and the crusher to the storage bin in the coal bunker, and then enters the coal mill through the feeder for grinding and pulverization, and passes through the air Sent to the screening device to obtain powder coke with a particle size of 200 μm, which is stored in the powder bin for later use. The powder coke in the powder bin is sent to the burner by the powder feeder, and is sprayed to the boiler through the powder coke channel 5 in the burner Inside;

[0075] S2. After the air is boosted by the blower, it enters the air preheater, absorbs the heat in the flue gas, and the temperature rises. Finally, the air is boost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com