The method of retracting and retracting the high temperature dust collection baffle

A high-temperature, dust-collecting hood technology, which is applied to dust collectors and other directions, can solve the problems of unloading and dust collection devices that cannot work normally, and achieve the effects of increasing effective capture capacity, reducing ineffective energy consumption, and improving dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

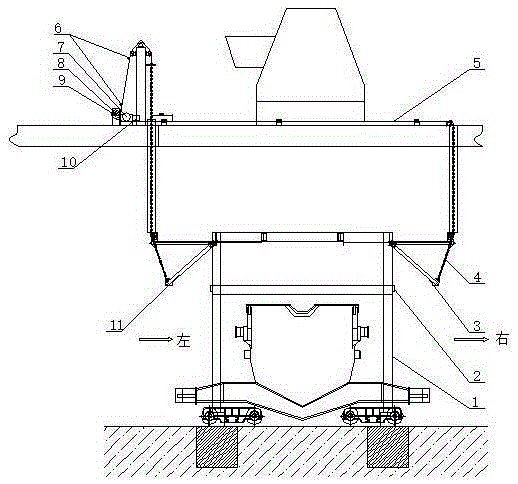

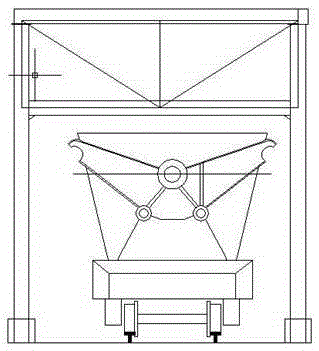

[0053] The method of retracting and retracting the high-temperature dust collection baffle is implemented at the position where the molten iron in the smelting blast furnace is poured into the molten iron tank, and a high-temperature dust collection cover device is installed. The high-temperature dust collection device includes a high-temperature dust collection baffle device, a high-temperature dust collection baffle retractable device, and the like.

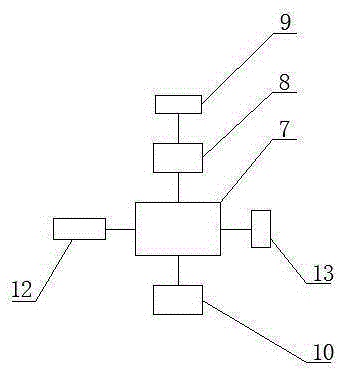

[0054] The method of retracting the high-temperature dust collection baffle is to install a high-temperature dust collection hood device at the position where the molten iron in the smelting blast furnace is poured into the molten iron tank. The high-temperature dust collection device includes a high-temperature dust collection baffle device, a high-temperature dust collection baffle retractable device, etc. The high-temperature dust collection baffle retractable device is composed of a motor 12, a reducer 7, a brake device 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com