High-temperature dust-collection baffle folding and unfolding apparatus

A technology of retractable device and baffle device, which is applied in the direction of dust collector, etc., can solve the problem of unloading and dust collection device not working normally, and achieve the effect of increasing effective capture capacity, reducing pollution, and reducing ineffective energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

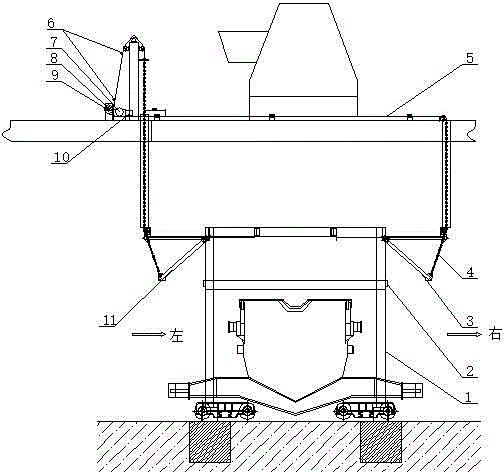

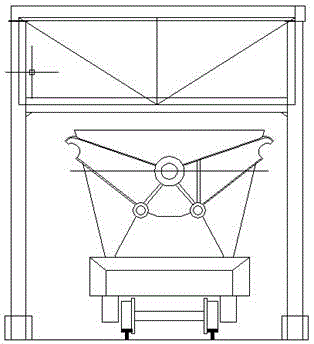

[0049] When the molten iron in the smelting blast furnace is poured into the crucible, a large amount of yellow smoke and dust overflows. In order to overcome the shortcomings of the existing ash unloading and dust collection devices that cannot work normally, the high-temperature dust collection baffle retractable device of the present invention is implemented.

[0050] A high-temperature dust collection hood device is installed at the position where the molten iron in the smelting blast furnace is poured into the crucible. The high-temperature dust collection device includes a high-temperature dust collection baffle device, a high-temperature dust collection baffle retractable device, etc.

[0051] The high-temperature dust collection baffle retractable device is installed at the position where the molten iron in the smelting blast furnace is poured into the crucible.

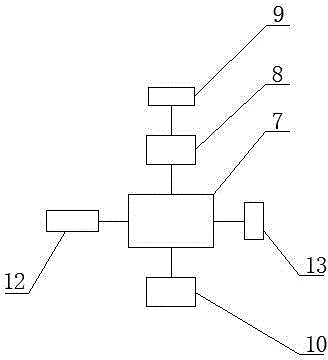

[0052]The dust device includes a high-temperature dust collection baffle device, a high-temperature dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com