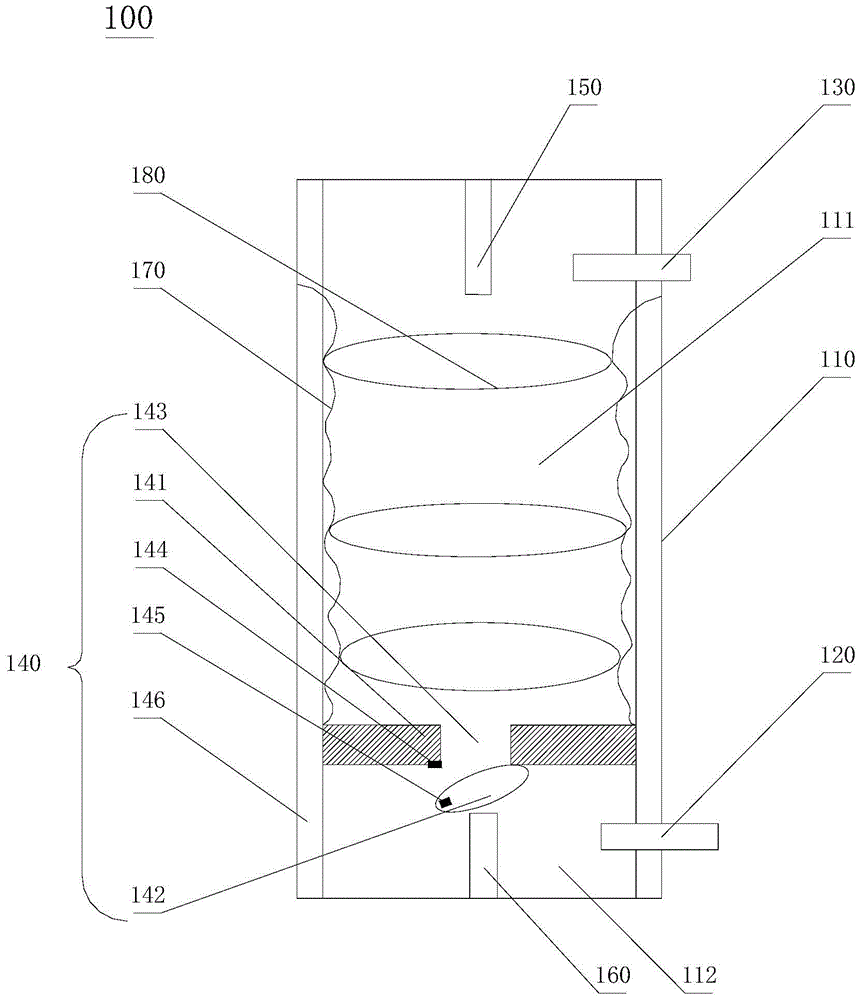

Vertical insulation water tank and air energy water heater

An insulated water tank, vertical technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of wasting hot water, low energy efficiency, inconvenience, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the vertical thermal insulation water tank and air energy water heater of the present invention clearer, the present invention will be further described in detail below in conjunction with specific drawings and specific embodiments.

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0022] The temperature of the cold water rises after the cold water filled in the ordinary water tank is mixed with the hot water, so the water heater burns water with a higher temperature every time. At present, the general users basically use the energy efficiency of boiling water between 45-55°C, rather than the energy efficiency of 15-55°C required by the national standard. The biggest disadvantage of air source water heaters is that the higher the water temperature, the lower the energy efficiency....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com