Multistage distributed water pump heat supply system and design method thereof

A heating system, distributed technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve the problems of mutual coupling of hydraulic conditions, damage to the hydraulic balance of heat users, and large diameter of the pressure equalizing tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

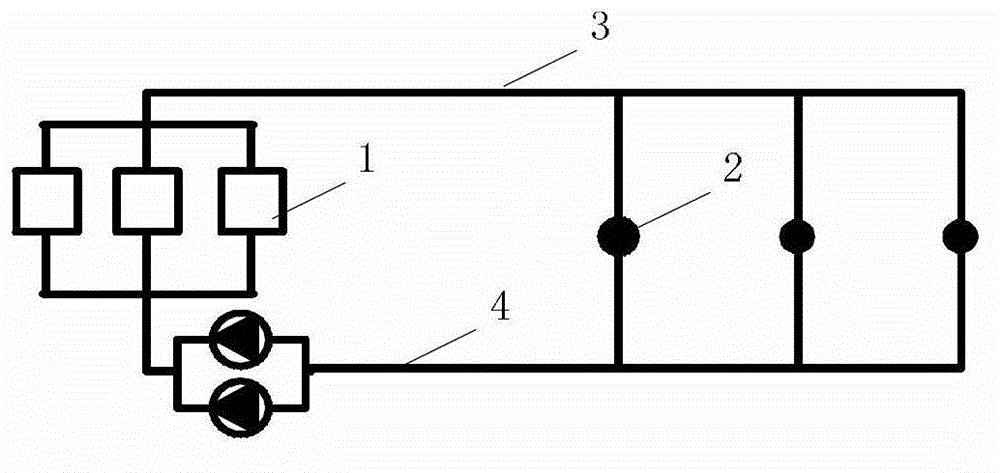

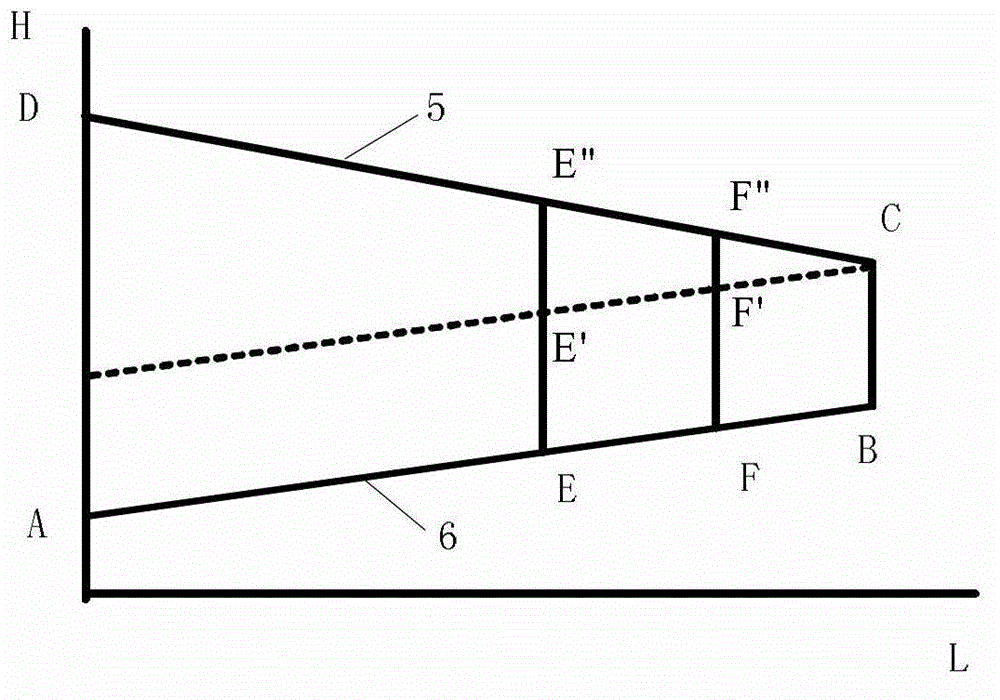

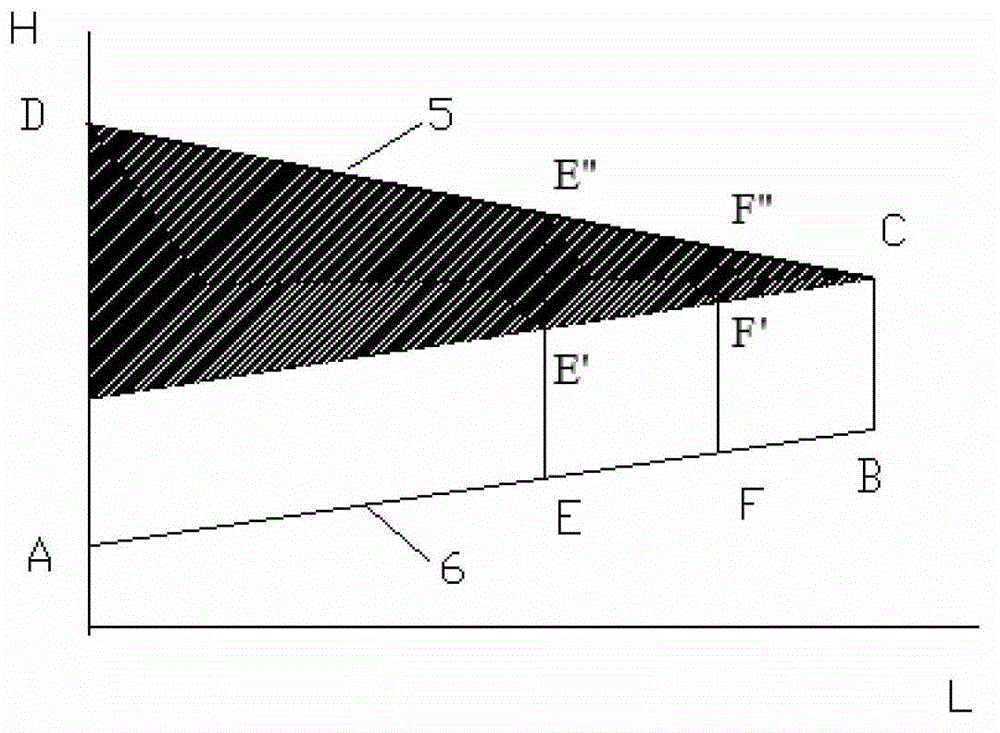

specific Embodiment approach 1

[0105] Specific implementation mode one: combine Figure 9 Describe this embodiment. The multi-stage distributed water pump heating system of this embodiment includes a heat source 1, a circulating water pump group 2 at the heat source, a water supply pipeline 7, a return water pipeline 8, and N-level distribution stations, each of which includes decoupling pipes 4. Grading booster pump 6. At least one set of secondary network loops; each set of secondary network loops is composed of heat user booster pump 3 and at least one heat user 5, heat source 1, circulating water pump group 2 at the heat source, water supply pipeline 7 and the return water pipeline 8 form the total heat supply circulation loop of the heating network, and a multi-level distribution station is arranged between the water supply pipeline 7 and the return water pipeline 8; the decoupling pipes 4 of the multi-level distribution stations are arranged in parallel, and each decoupling pipe 4 One end of each deco...

specific Embodiment approach 2

[0108] Specific implementation mode two: combination Figure 9 To describe this embodiment, the diameter of each decoupling pipe 4 in this embodiment is smaller than or equal to the diameter of the water supply pipeline 7 or the return water pipeline 8 . In this embodiment, the diameter of the decoupling pipe is less than or equal to the maximum diameter of the connecting pipe, so that the required installation space is small, the manufacturing cost is low, it is easy to manufacture and install, and can meet the needs of actual heating. Others are the same as the first embodiment.

specific Embodiment approach 3

[0109] Specific implementation mode three: combination Figure 9 To describe this embodiment, the diameter of each decoupling pipe 4 in this embodiment is larger than the diameter of the water supply pipeline 7 or the water return pipeline 8 . In this embodiment, the diameter of the decoupling pipe is larger than the maximum diameter of the connected pipes, so it is easy to meet the strength requirements of the decoupling pipe, easy to manufacture and install, and can meet the needs of actual heating. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com