Automatic sealing machine

A technology of automatic sealing machine and frame, which is applied in the direction of bottling machines, bottle filling, flanged bottle caps, etc., which can solve the problems of heavy replacement and maintenance workload, reduced labor intensity, low efficiency, etc., to reduce maintenance costs and The effect of reducing the workload, improving the safety of use, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

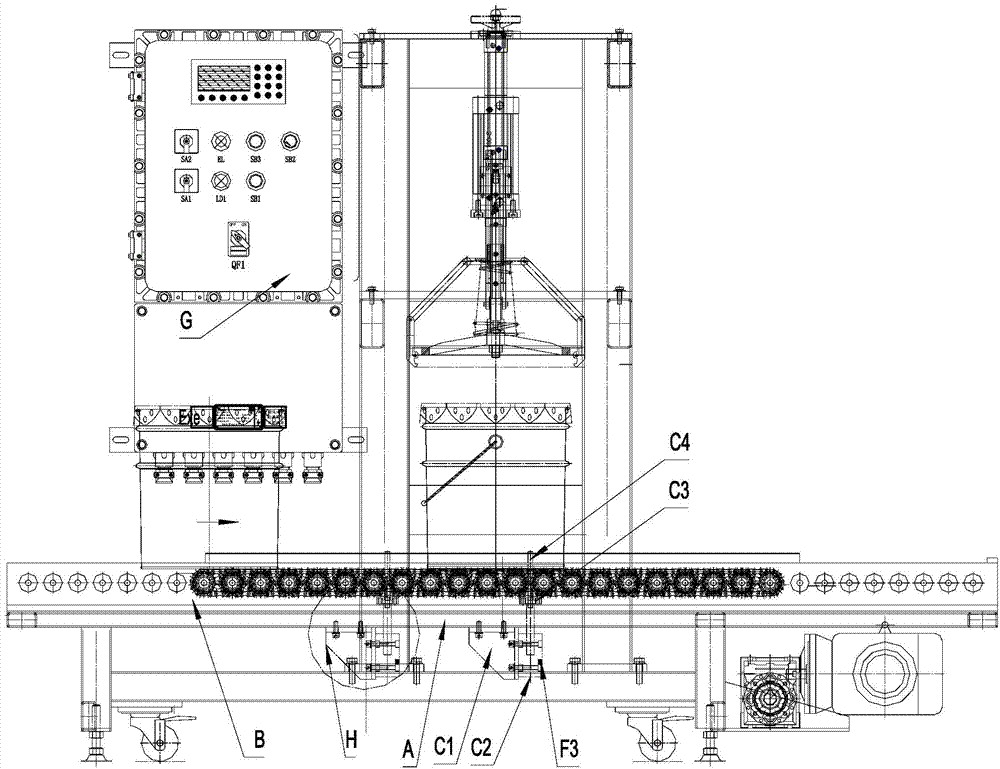

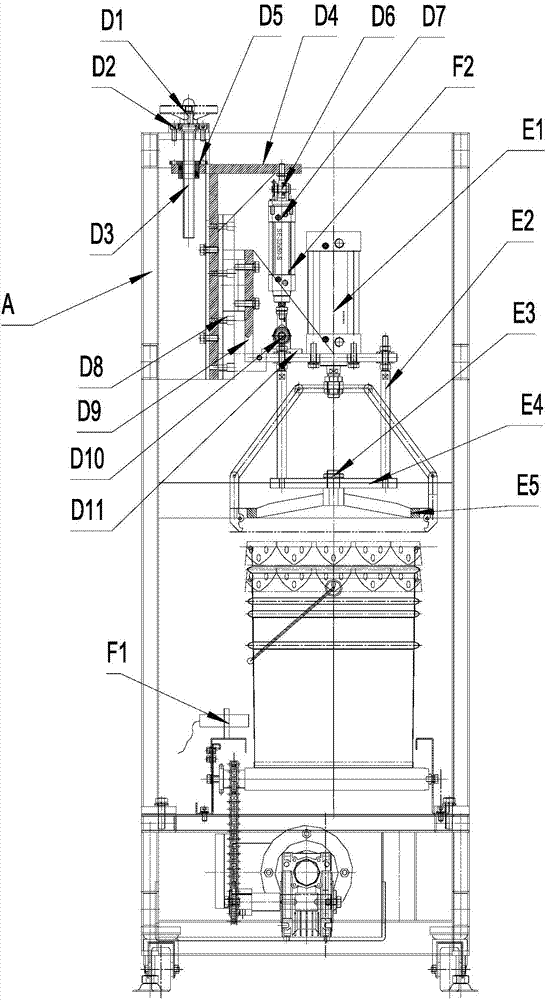

[0015] like figure 1 and 2 The automatic sealing machine shown is composed of a frame, a transmission line, a positioning mechanism, a new type of elevator sealing mechanism, a detection device, an electrical controller and other actuators. Among them, the transmission line can be realized by different transmission forms such as belt conveyor, power roller conveyor, chain conveyor, and chain plate conveyor.

[0016] Positioning mechanism: The positioning cylinder base C1 is fixed on the frame A, the cylinder C2 is fixed on the cylinder base C1; the positioning rod mounting plate C3 is fixedly connected with the piston rod of the cylinder C2, and the positioning rod C4 is mounted on the positioning rod mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com