Frequency converting control method, controller and refrigerator

A frequency conversion control and controller technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve the problems of noisy users, high energy consumption, etc., to improve user experience, save power resources, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

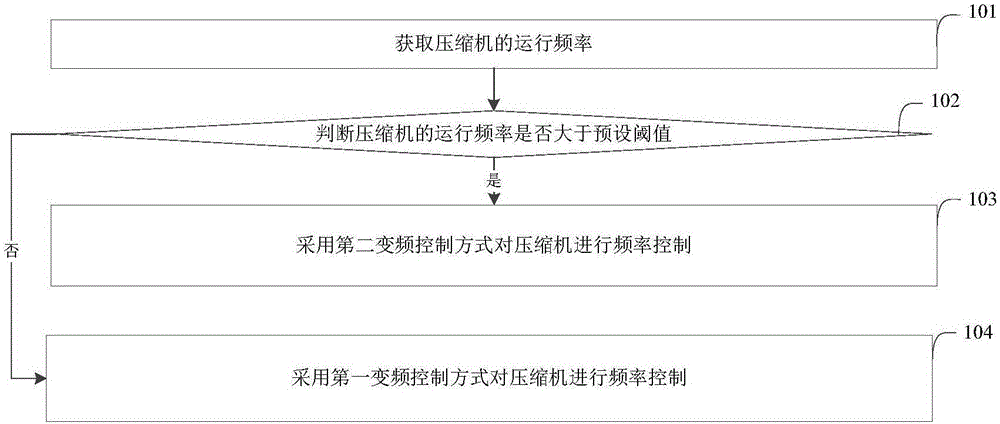

[0037] An embodiment of the present invention provides a flow chart of a frequency conversion control method, see figure 1 , the method includes the following steps:

[0038] Step 101: Obtain the operating frequency of the compressor.

[0039] In this step, the current running frequency of the compressor is obtained. Among them, the current operating frequency of the compressor is generally determined according to the ambient temperature of the refrigerator, the temperature in the freezer and the operating time and other parameters. Generally, the operating frequency of the compressor is relatively high under high load conditions, and the In some cases, the operating frequency of the compressor is relatively low.

[0040] Step 102: Judging whether the running frequency of the compressor is greater than a preset threshold, if yes, go to step 103; otherwise, go to step 104.

[0041] When the compressor runs at a high frequency, it is easy to generate high noise, which affects...

Embodiment 2

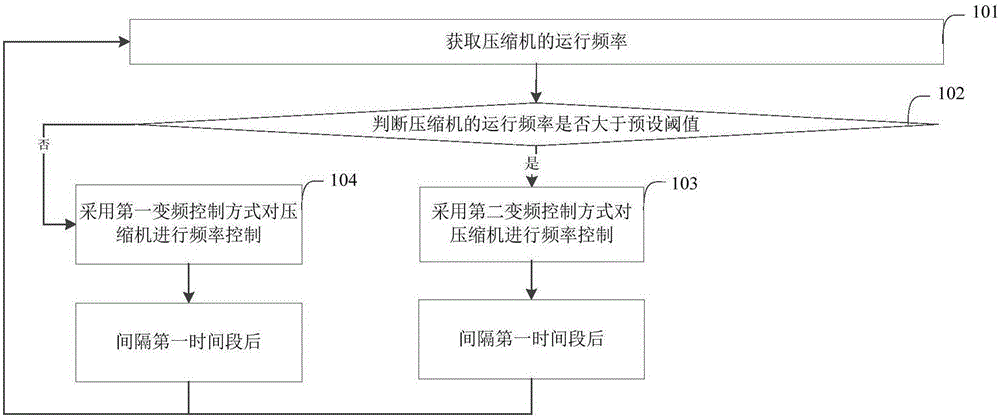

[0056] The embodiment of the present invention provides a further supplement to the method provided in the previous embodiment.

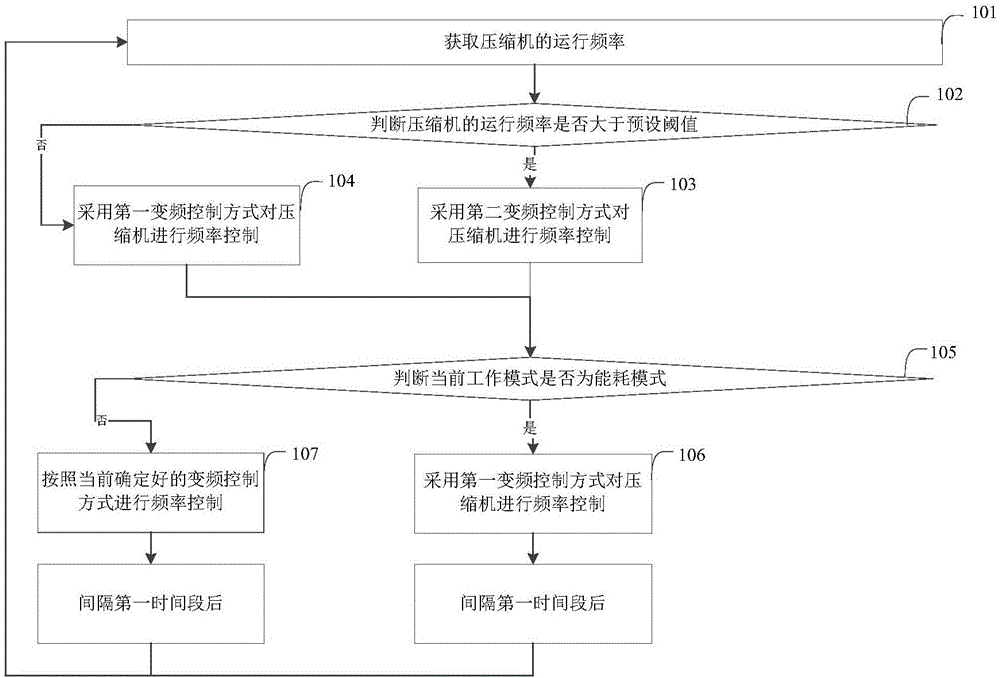

[0057] In this example, see image 3 , the above-mentioned frequency conversion control method further includes:

[0058] Step 105: Determine whether the current working mode is the energy consumption mode, if so, go to step 106, otherwise go to step 107, that is, perform frequency control according to the currently determined frequency conversion control method.

[0059] Step 106: Perform frequency control on the compressor by using the first frequency conversion control method.

[0060] Step 107: Perform frequency control according to the currently determined frequency conversion control mode. Here, the currently determined frequency conversion control mode refers to: the frequency conversion control mode determined according to the current operating frequency of the compressor.

[0061] Here, the energy consumption mode refers to a mode operat...

Embodiment 3

[0064] The embodiment of the present invention provides a controller, see Figure 4 , the controller includes: an acquisition unit 41, a first judging unit 42 and a control unit 43, wherein:

[0065] An acquisition unit 41, configured to acquire the operating frequency of the compressor;

[0066] The first judging unit 42 is configured to judge whether the operating frequency of the compressor acquired by the acquiring unit 41 is greater than a preset threshold;

[0067] The control unit 43 is configured to use the second frequency conversion control method to control the frequency of the compressor when the first judging unit 42 determines that the operating frequency of the compressor is greater than a preset threshold; and when the first judging unit determines that the compressor is When the operating frequency is less than or equal to the preset threshold, the frequency control of the compressor is carried out in the first frequency conversion control mode.

[0068] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com