Graded storage injection molding machine

An injection molding machine and material storage technology, applied in the field of graded material storage injection molding machines, can solve the problems of low hydraulic system efficiency, reduced service life, and quality fluctuations, and achieve precise control, energy saving, improved service life, and stable plasticizing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described with embodiment below in conjunction with accompanying drawing.

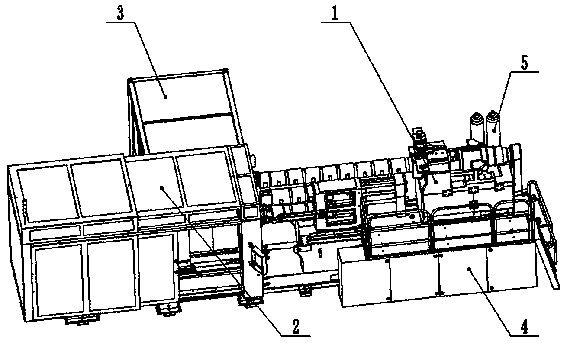

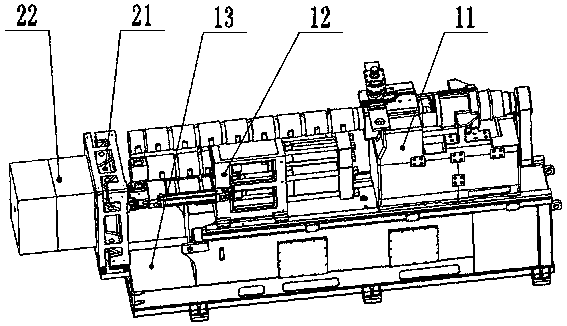

[0039] Such as figure 1 and figure 2 As shown, the present invention provides a kind of graded storage injection molding machine, which comprises a plasticizing injection part 1, a clamping part 2, a product laying part 3, an electrical system 4 and a hydraulic system 5, wherein the plasticizing injection part 1 It includes a bracket 13, a plasticizing part 11, a graded storage injection part 12, a fixed template 21 and a mold 22, the mold 22 is installed on the fixed template 21, the fixed template 21 is installed on the end face of the bracket 13, the plasticized part 11 and the graded storage The injection part 12 is mounted on the bracket 13 .

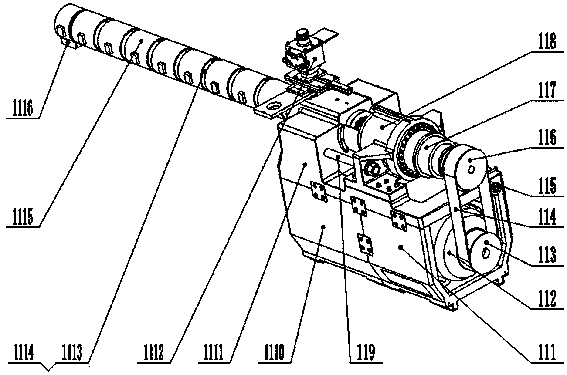

[0040] Such as image 3 and Figure 4As shown, the plasticizing part 11 includes a plasticizing platform 1111, a plasticizing moving base 1110 and a motor moving base 111, the plasticizing moving base 1110 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com