Ironing table capable of using waste steam of iron

A steam outlet and steam inlet technology, applied in applications, household appliances, washing devices, etc., can solve the problems of waste, hidden dangers, power consumption of electric heating wire drying sponge, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

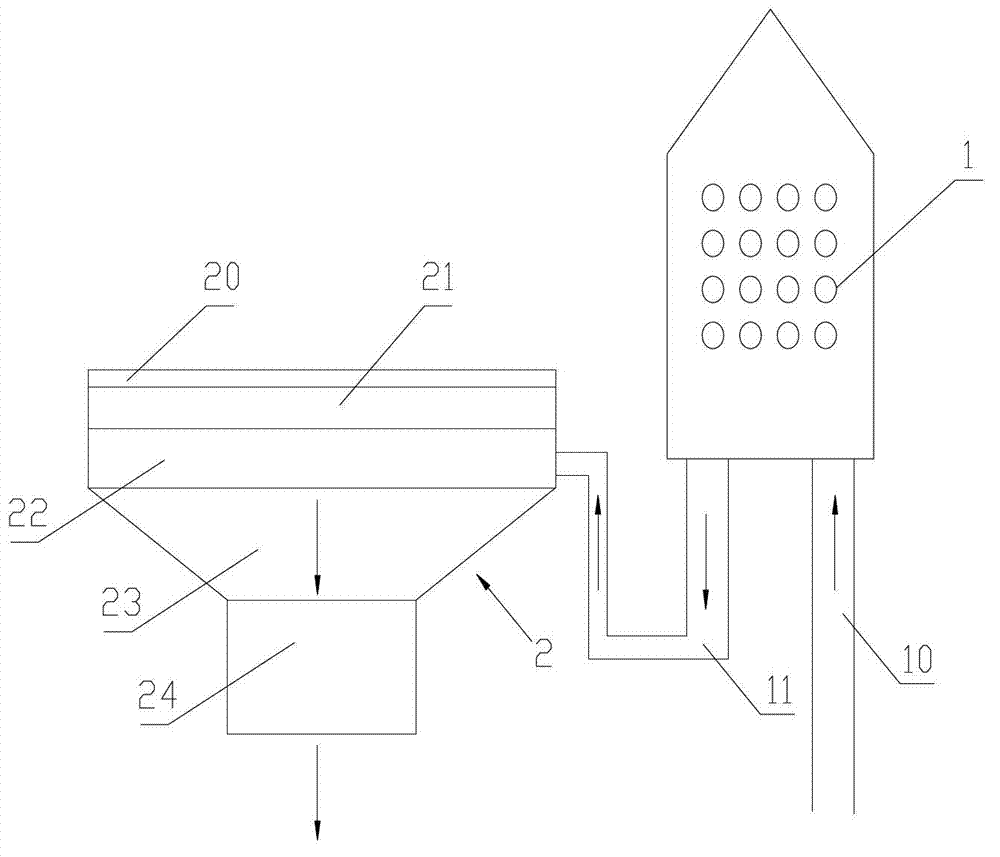

[0011] Such as figure 1 As shown, it is an embodiment of an ironing table that can utilize iron waste steam in the present invention, which includes an ironing table 2 and an iron 1. The ironing table includes a body 23, and a layer of sponge 21 is laid on the top surface of the body. Lay a layer of cushion cloth 20 on it, the body is provided with an exhaust fan 24 below the sponge, the iron is provided with a steam inlet 10 and a waste steam outlet 11, and a pipe 22 is also laid between the body and the sponge. , the inlet of the pipeline is connected to the waste steam outlet 11 of the iron 1, and the outlet of the pipeline 22 is connected to a collection bucket.

[0012] The body 23 is a hollow platen structure, and the top surface of the body is provided with a grid support sponge 21, and an s-shaped pipe is laid under the sponge, and the s-shaped pipe is wound to form various structures, such as a circle, an ellipse or an A shape, The exhaust fan 24 is located at the bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap