Mechanical locking limited slip differential

一种防滑差速器、机械锁止的技术,应用在机械设备、差速传动装置、皮带/链条/齿轮等方向,能够解决差速器结构复杂、不能完全锁止等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

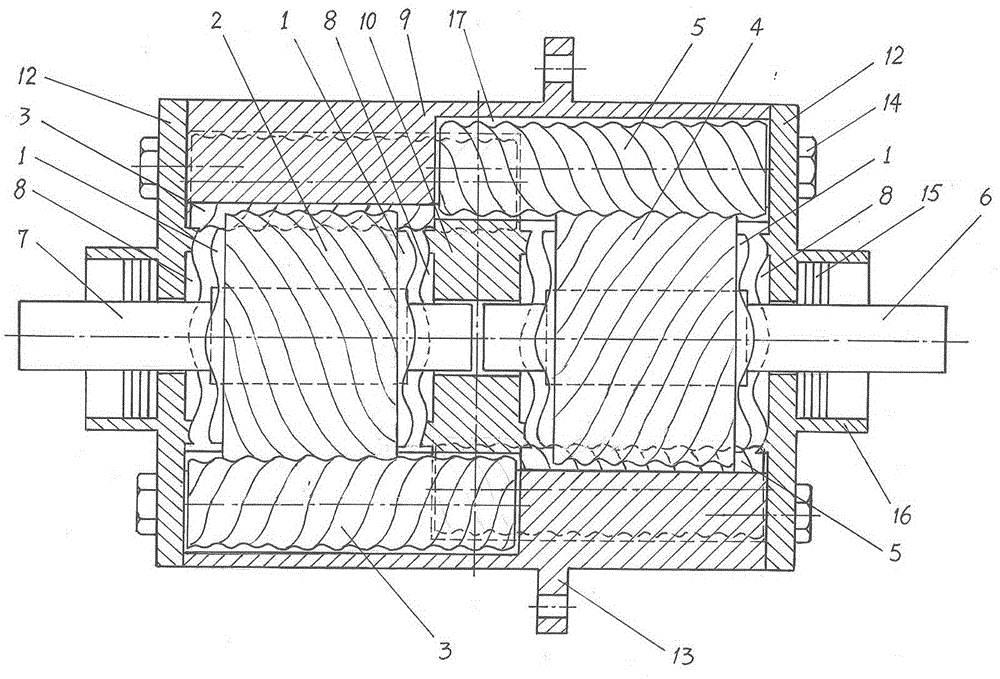

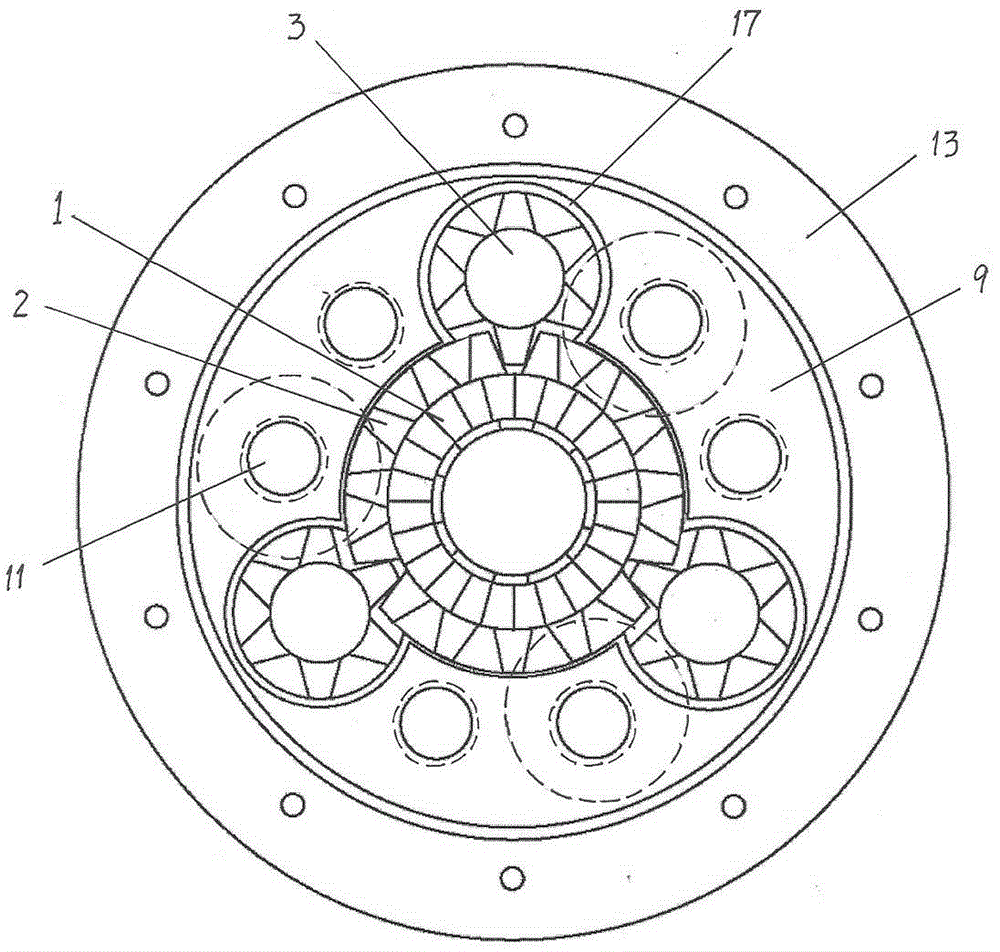

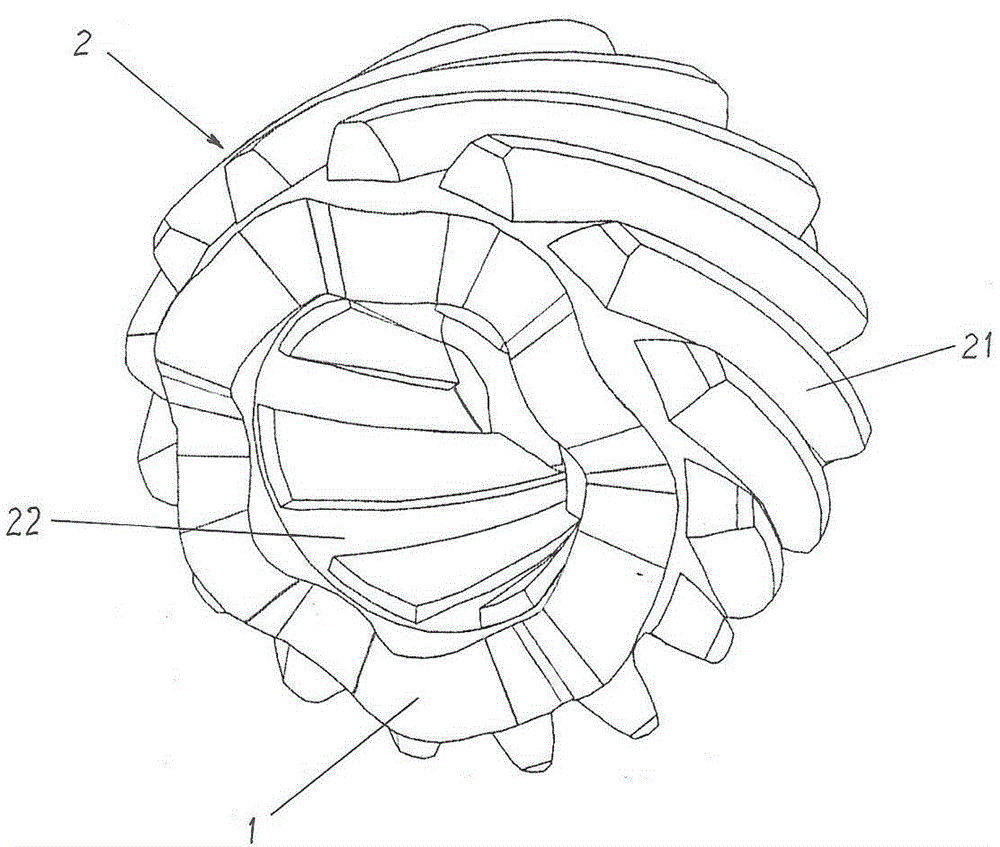

[0027] like figure 1 As shown, the housing 9 is cylindrical, and a cylindrical axial through hole is opened inside to form a cylindrical inner cavity. A flange 13 for fixed connection with the drive axle of the automobile is arranged on the outer surface of the housing 9 . A central stopper 10 is blocked and fixed in the middle of the inner cavity of the housing 9 to divide the inner cavity of the housing into a left chamber and a right chamber. An axial core hole is opened on the center block 10 to support the left and right half shafts. The center stop 10 may be a unitary structure. In order to simplify the production, it can also be divided into a symmetrical two-body structure with opposite backs, which are respectively embedded and fixed in the middle of the inner cavity from the inner cavity ports on both sides of the housing. On both sides of the central stopper 10, circular fixed meshing teeth 8 are arranged respectively. Each tooth tip and tooth root on the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com