Method for designing blade sections of helicopter rotors

A technology for helicopter rotor and blade profiles, which is applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems that the structure cannot be obtained, and the topological type of the blade structure cannot be changed, so as to achieve the effect of improving performance and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

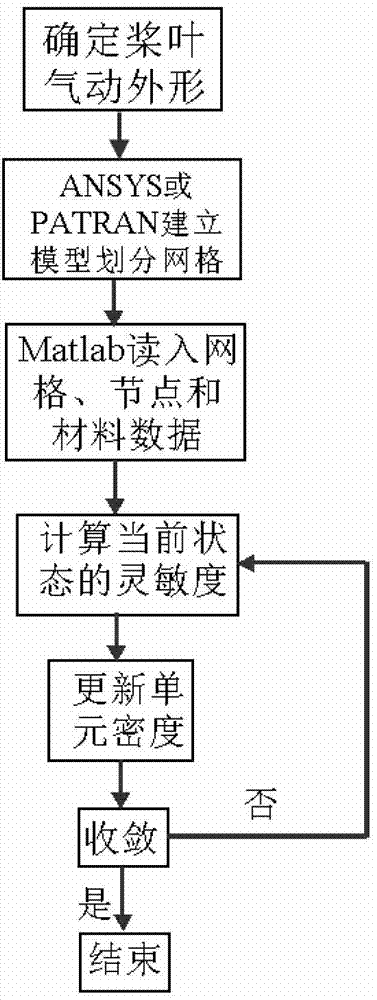

Method used

Image

Examples

Embodiment

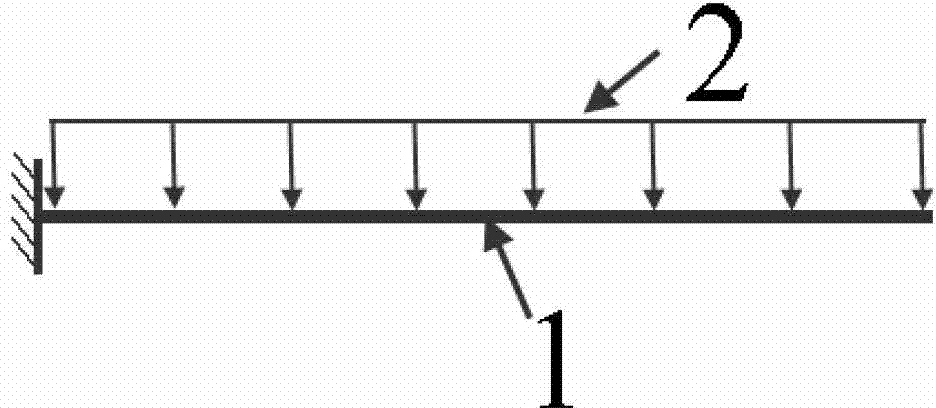

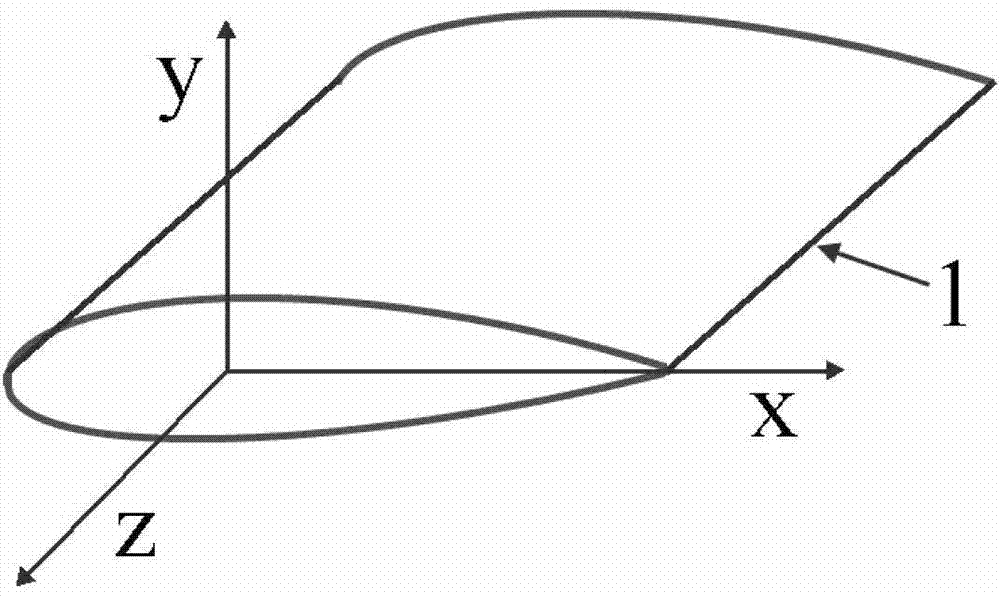

[0101] In this example, the rotor blade section design method based on topology optimization proposed by the present invention is applied to the actual helicopter blade design. like Figure 5 As shown, the blade bears the same resistance 4 and vertical lift 5 as the air flow direction 3, and the resultant force 6 of the lift and resistance is shown in the figure. To simplify the optimization process, it is assumed that the aerodynamic center coincides with the shear center of the blade, so no additional bending load is generated. The NACA0018 airfoil is adopted, and the chord length of the blade is 1m. Since the shape of the blade has aerodynamic performance, it is not considered here. The optimization method proposed by the present invention is used to obtain the cross-sectional structure of the blade as follows: Figure 6 As shown, the black cells in the figure represent the density of 1, the white cells represent the density of 0, and the gray cells are in between. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com