Method for determining amount of ball placement for camera module

A camera module and ball planting technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc., can solve the problems of increasing packaging costs and skewing of chips 12, so as to avoid skewing, alleviate height unevenness, The effect of improving the packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

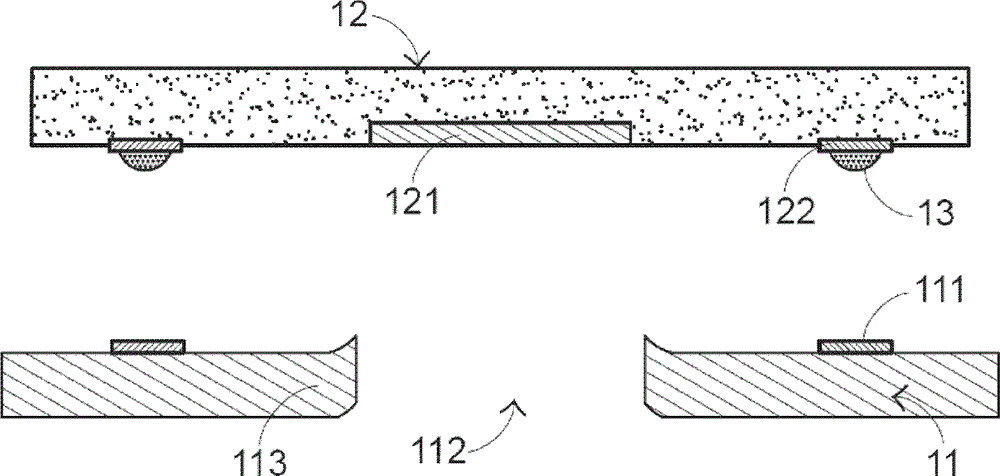

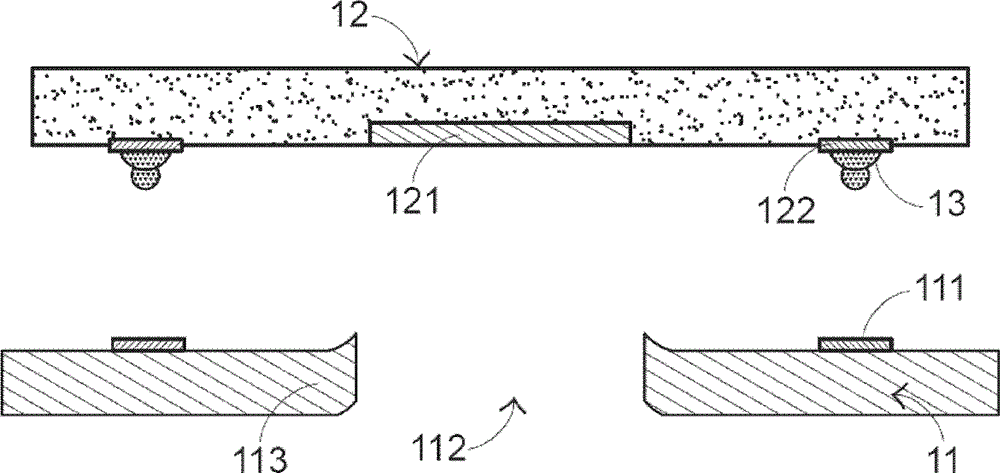

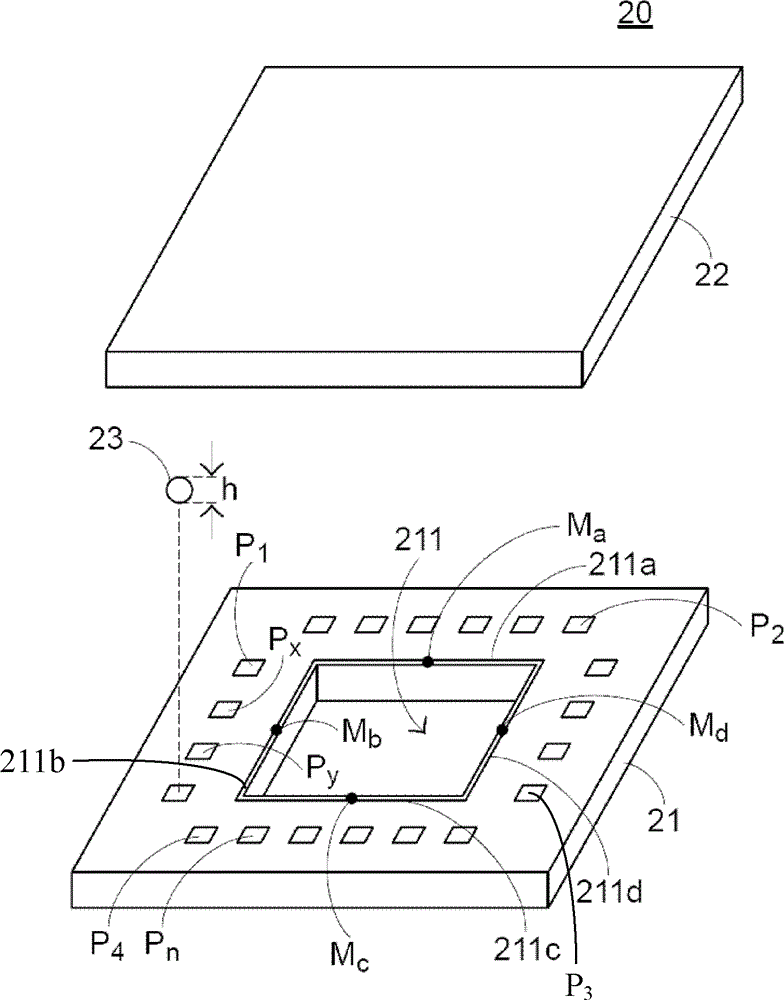

[0025] Please refer to image 3 , image 3 It is a schematic diagram of the camera module of the present invention. Such as image 3 As shown, the camera module 20 includes a substrate 21 and a chip 22 . The substrate 21 has an opening 211 and a plurality of contacts Pn, where n=1˜n and n is a positive integer. The opening 211 has four borders 211a, 211b, 211c, 211d, and each contact Pn is used to receive at least one conductive block, especially a ball plant 23 made of conductive metal, so as to electrically connect and fix the substrate 21 and the chip 22 . In addition, the planted ball 23 has a planted ball height h.

[0026] The method for determining the number of planted balls of the camera module in the present invention is as follows, please refer to Figure 4 , Figure 4 It is a schematic diagram of the machine platform of the present invention. Such as Figure 4 As shown, the machine 30 has a platform 31 and an image capture device 32, wherein the platform 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com