Metal tube for a vacuum cleaner, shaped with an engaging means for a suction tool or for a connection device

A technology for vacuum cleaners and connecting equipment, applied in the field of metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

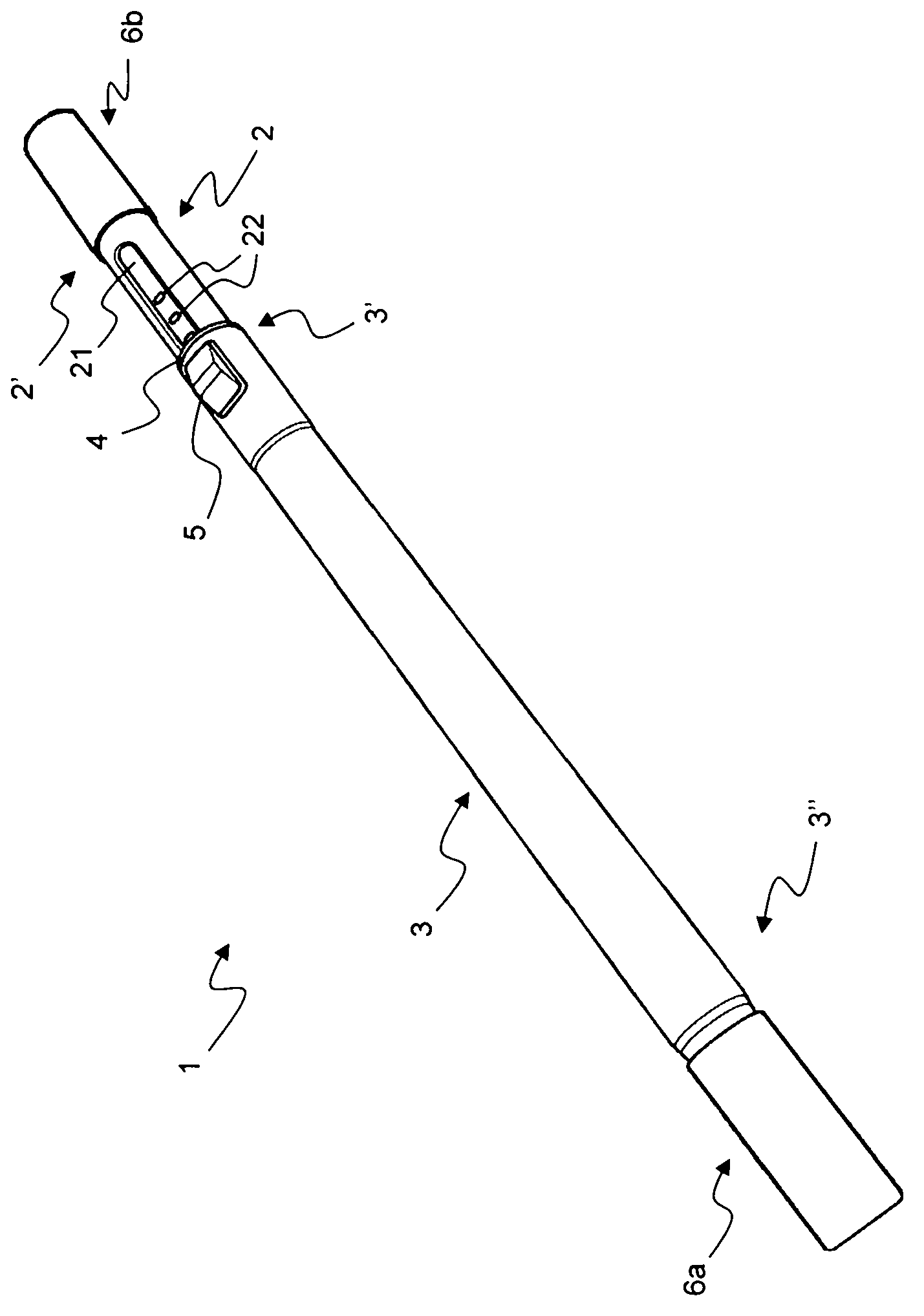

[0024] figure 1 A telescopic extension 1 according to an embodiment of the invention is shown.

[0025] The telescopic extension 1 comprises an inner tube 2, an outer tube 3, a sleeve 4, a restraint device (in figure 1 not shown), advancing the slider (in the figure 1 not shown in ) and operation button 5.

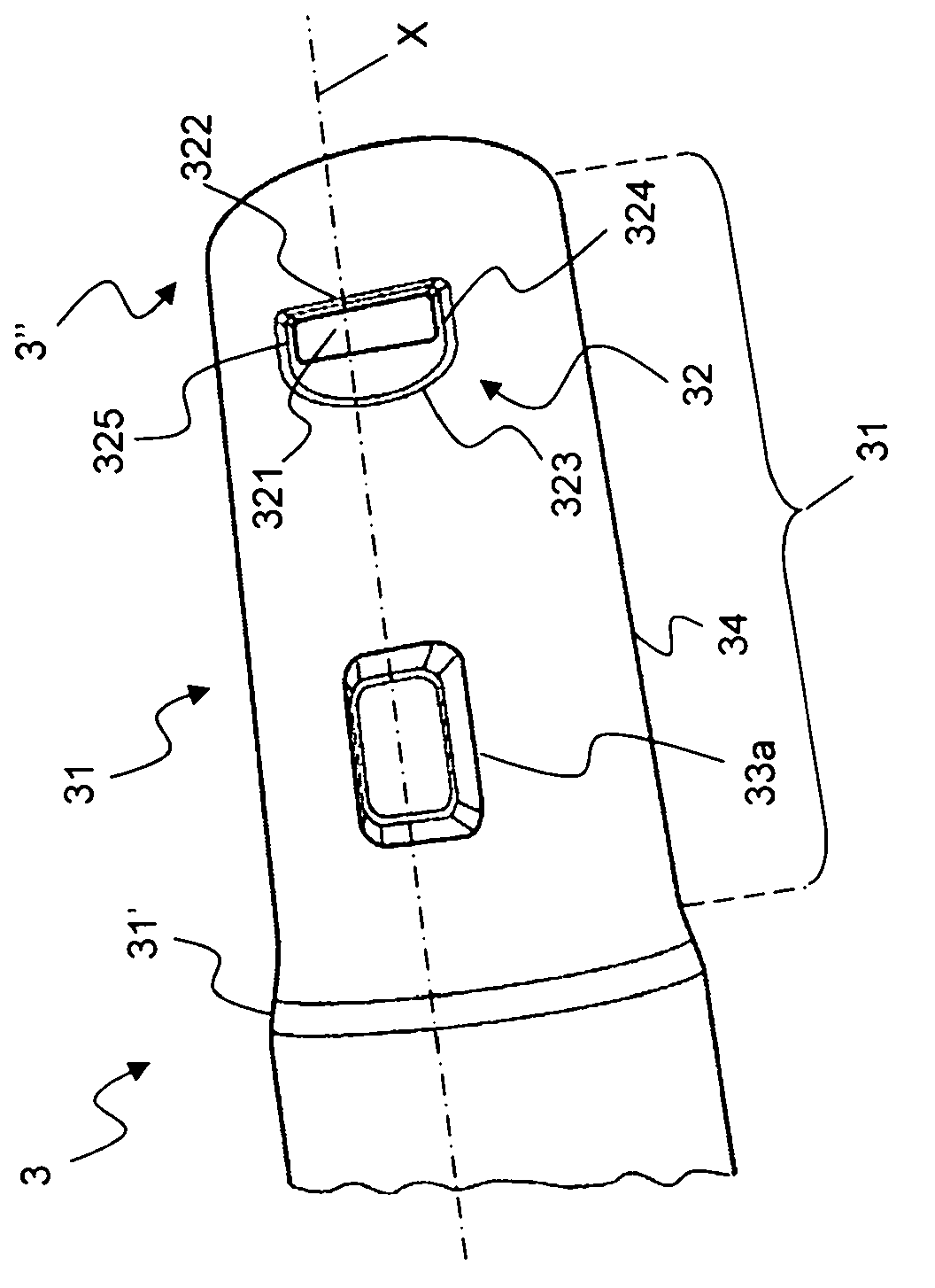

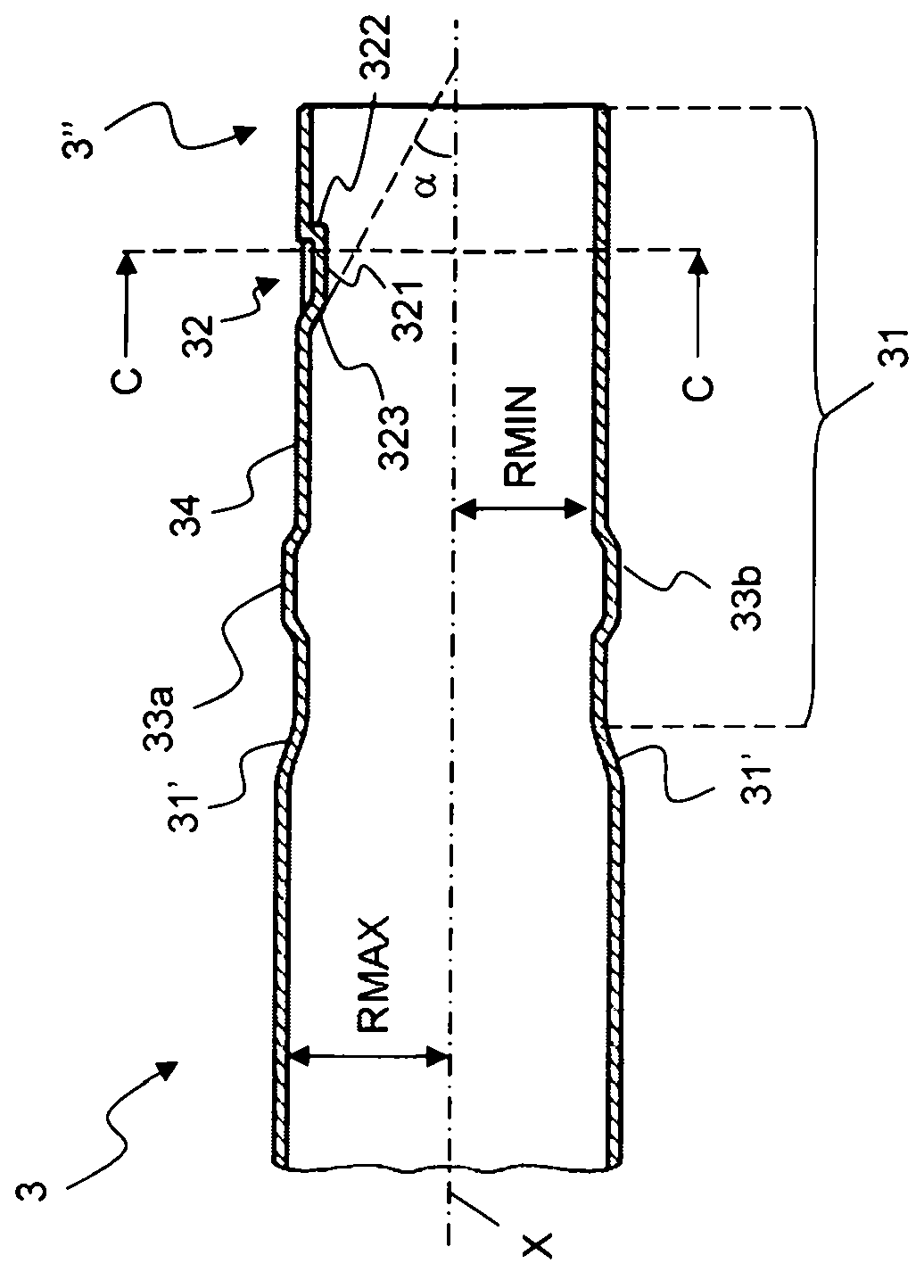

[0026] The inner tube 2 has a first end (or input end) 2' and a second end (or output end) (not shown in the figures). The outer tube 3 has a first end (or input end) 3' and a second end (or output end) 3". The telescoping extension 1 thus has an input end of the inner tube 2 as input end 2' and the output end 3" of the outer tube 3 as the output end.

[0027] The inner tube 2 has a substantially circular cross section. The outer surface of the inner tube 2 comprises an axial groove 20 having a bottom wall 21 in which a row of notches 22 of predetermined shape are formed.

[0028] The inner tube 2 and the outer tube 3 are able to slide sealingly one inside the other....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap