Oil pumping rod anti-fouling device

A sucker rod and anti-fouling technology, which is applied to cleaning equipment, wellbore/well components, earth-moving drilling, etc., can solve the problems of inability to use sucker rod and pollution, and achieve the effect of simple structure and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

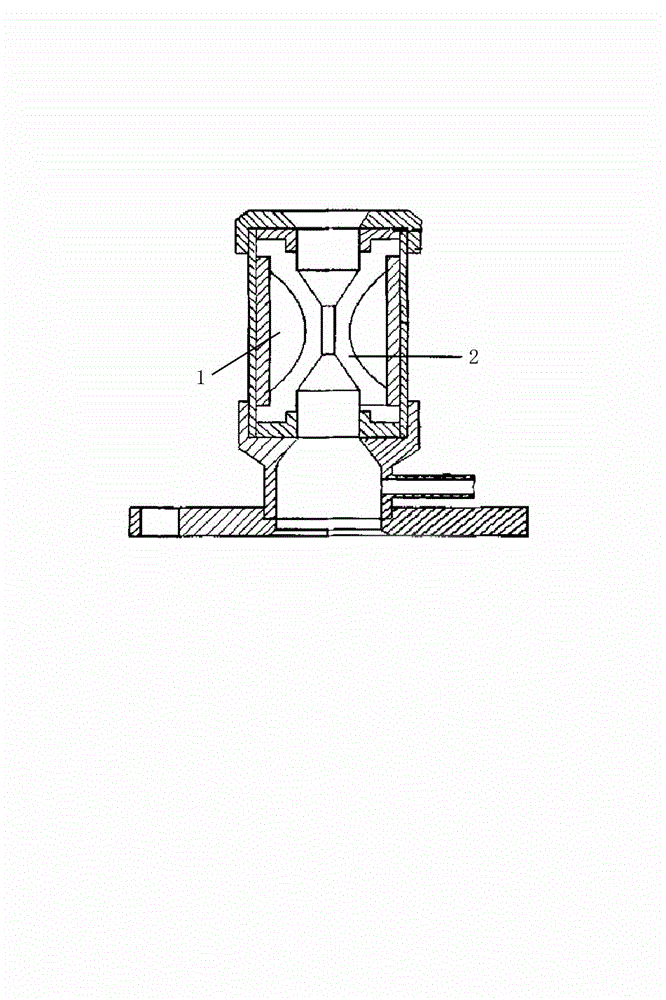

[0010] The sucker rod antifouling device according to the present invention includes a device body 1, and an elastic rubber cylinder 2 is arranged inside the body 1. The elastic rubber cylinder 2 is a C-type rubber cylinder connected by two back-to-back types, and the connecting part of the two elastic rubber cylinders 2 There is a through hole in the center of the main body 1, and a through hole is also provided in the center of the main body 1. The two through holes overlap at the center point of the same horizontal plane. , the base is fixedly connected with the oil well, and the center of the base is correspondingly provided with a through hole, and the cross section of the connecting part of the two elastic rubber tubes 2 is larger than the maximum cross section of the centralizer.

[0011] When in use, when the sucker rod passes through the elastic rubber tube 2 during the process of lifting the sucker rod, the through hole of the elastic rubber tube 2 will hold the sucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com