Bottom testing method

A test method and a technology for detecting components, which are applied in the direction of testing optical properties, measuring electricity, measuring devices, etc., can solve problems such as limiting the scope of application, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

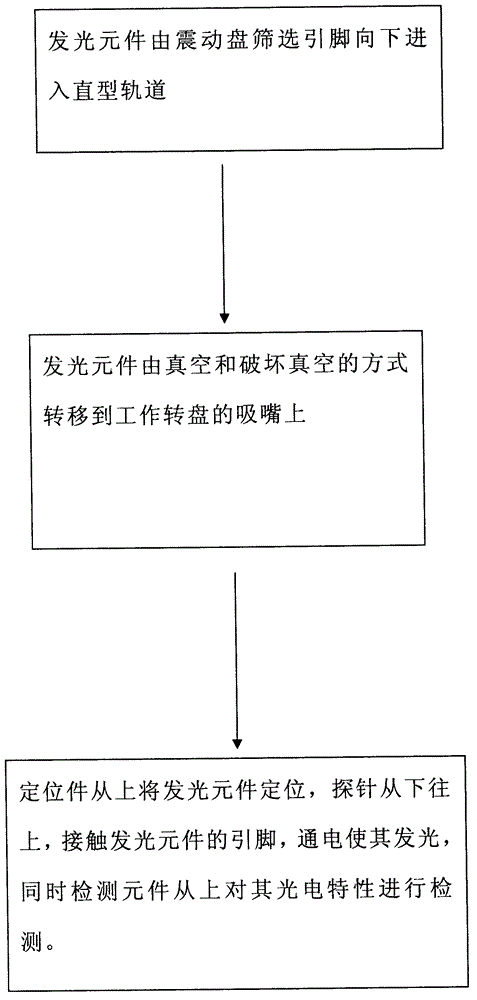

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments. see figure 1 , the present invention provides a preferred bottom testing method, the method steps comprising:

[0012] (1) The light-emitting element is screened by the vibrating plate and enters the straight track downward;

[0013] (2) The light-emitting element is transferred to the suction nozzle of the working turntable by vacuum and vacuum breaking;

[0014] (3) The positioning piece positions the light-emitting element from above, and the probe touches the pins of the light-emitting element from bottom to top, and energizes it to make it emit light. At the same time, the detection element detects its photoelectric characteristics from above.

[0015] The present invention is mainly aimed at the improvement of the light-emitting element testing method. The above description is only a preferred embodiment of the present invention, and it does not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com