Method and device for measuring and controlling casting powder of continuous caster crystallizer

A technology of mold powder and measurement and control method is applied in the field of continuous casting automation control to achieve the effect of enhancing quality stability and realizing performance tracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below by specific examples.

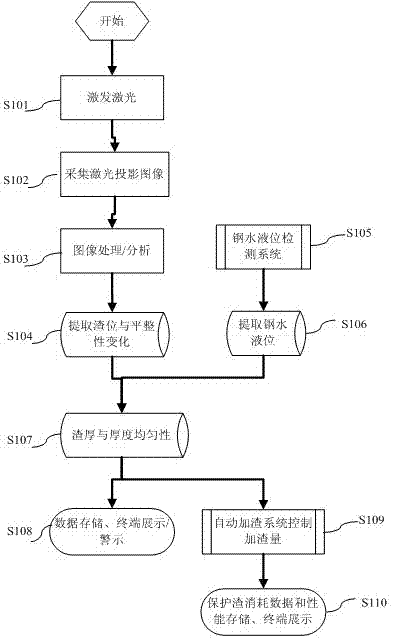

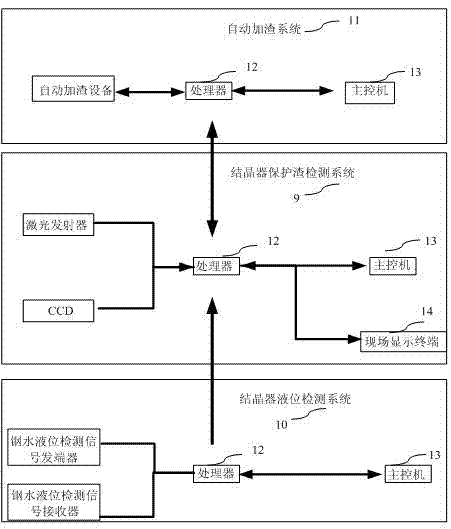

[0022] figure 1 The flow chart of the method for measuring and controlling mold slag in the mold of a continuous casting machine provided by the embodiment of the present invention, as shown in figure 1 As shown, the system enters the measurement and control process after starting, and runs from step S101 to step S110 in sequence.

[0023] Step S101, triggering a laser light source to emit laser light.

[0024] In step S102, the area array CCD monitors the mold flux surface and the mold side wall in real time, and collects laser projection images.

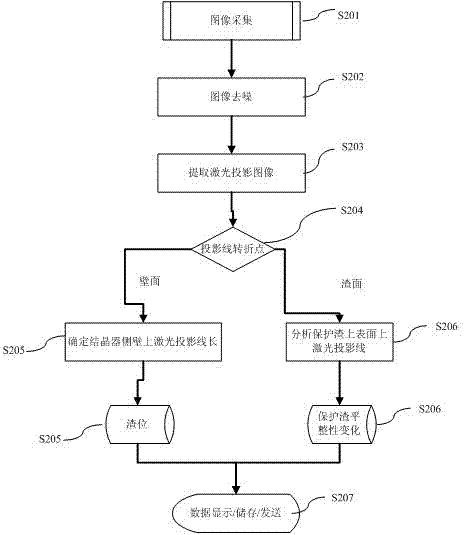

[0025] Step S103, the processor performs corresponding analysis and processing on the laser projection image, the analysis and processing process is as follows: figure 2 shown.

[0026] Step S104, the processor extracts the mold slag position L slag and changes in the flatness of the mold slag surface.

[0027] Step S105, the liquid level de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com