Automatic finished-tire separation device

A technology for automatic separation and finished tires, applied in storage devices, transportation and packaging, etc., can solve the problems of limited length of multi-layer forks, high operation and maintenance costs, and high construction costs, and reduce one-time investment and recurring costs. , Improve work efficiency and economic benefits, reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

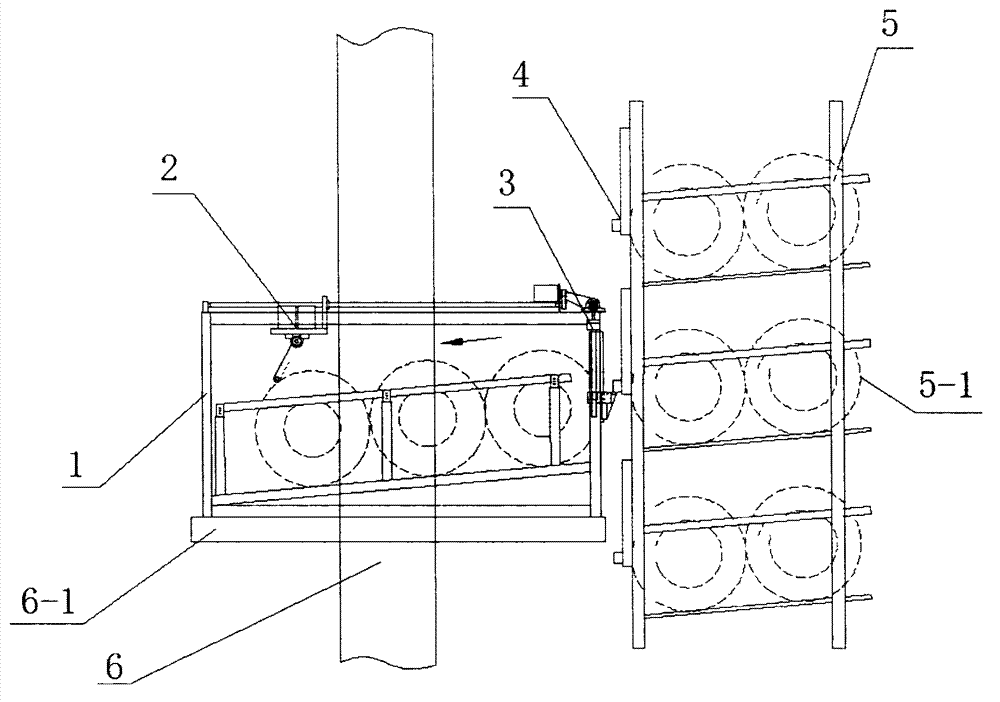

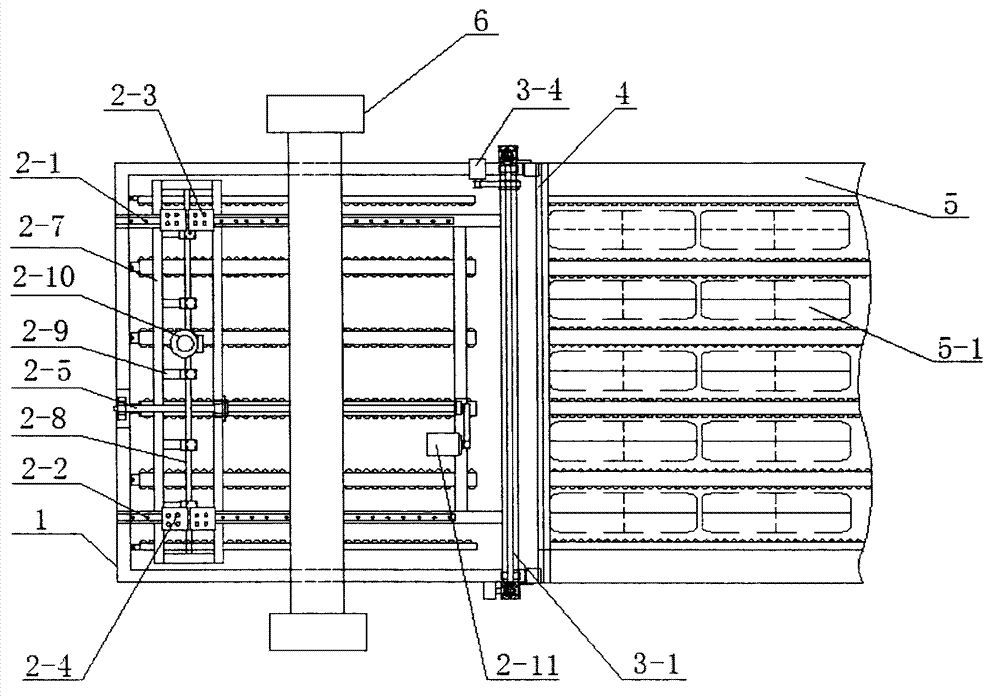

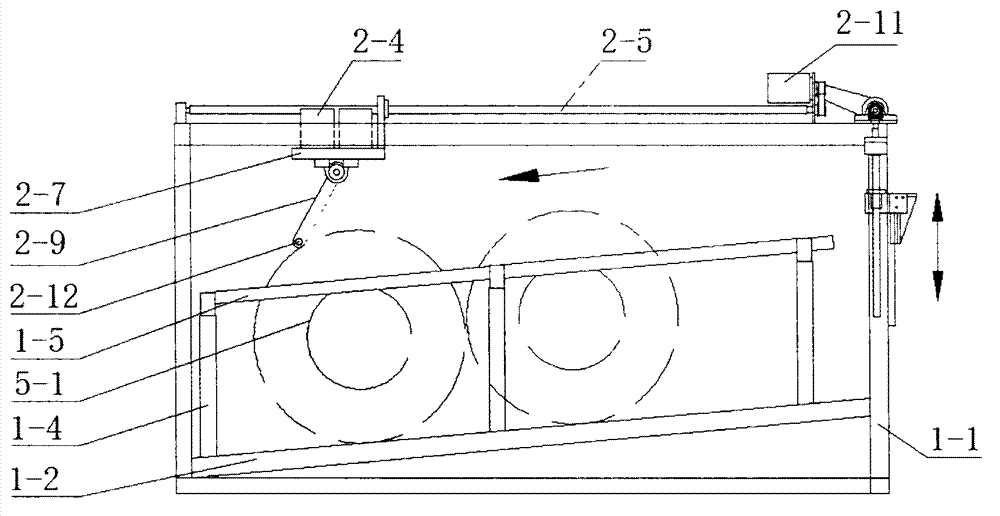

[0029] Describe the implementation process of the present invention in detail in conjunction with accompanying drawing, as Figure 1-Figure 8 shown.

[0030] The present invention is composed of a tire temporary storage box 1, a tire release mechanism 2 installed on the tire temporary storage box, a finished tire storage exit gate lifting mechanism 3 and an exit gate mechanism 4 installed at the finished tire storage exit. On the cargo platform 6-1, it corresponds to the outlet of the finished tire storehouse 5.

[0031]The tire temporary storage box 1 is composed of a rectangular frame 1-1, an inclined base plate 1-2, a guide rail support beam A1-3-1, a guide rail support beam B1-3-2, a tire rolling guide bracket 1-4, and a fluent strip 1-5 Composition; the rectangular frame is composed of four longitudinal beams, four beams, and four columns fixed together. The length of the beam is determined according to the number of rows of tires taken at one time, and the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com