Variable stiffness anti-impact steel wire rope vibration isolator

A steel wire rope, variable stiffness technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem that wire rope vibration isolators cannot be applied to large impact vibration isolation, etc., and achieve the effect of protecting wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

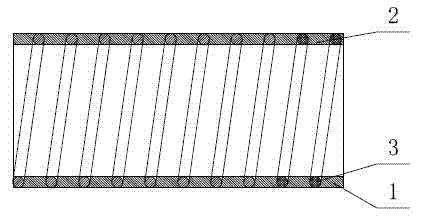

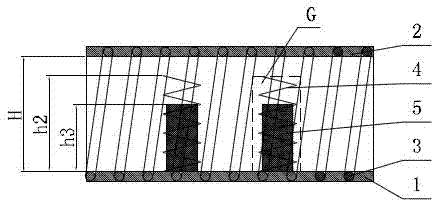

[0016] see figure 2 As shown, a kind of variable stiffness shock-resistant steel wire rope vibration isolator of the present invention comprises a lower base plate 1, an upper base plate 2, a steel wire rope 3 and a variable stiffness module G; Both sides; the variable stiffness module G is located between the upper base plate 2 and the lower base plate 1, and inside between the steel wire ropes 3 on both sides, and is composed of an anti-compression coil spring 4 and a rubber guide post 5; one end of the rubber guide post 5 It is fixed on the lower base plate 1, and the anti-compression coil spring 4 is set on the rubber guide post 5; more than two groups of variable stiffness modules G are arranged on the lower base plate 1.

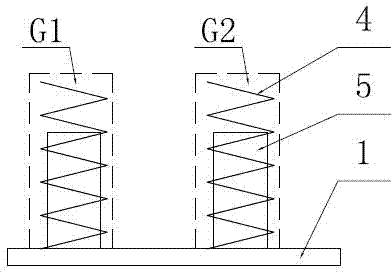

[0017] see image 3 As shown, the two sets of variable stiffness modules G of the present invention are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap