Heat recovery device

A technology of heat recovery device and air inlet pipe is applied in the field of heat recovery device, which can solve the problems of heat loss, insufficient heat absorption by heat exchanger, energy waste, etc., so as to reduce the usage amount, improve the usage efficiency, and improve the operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

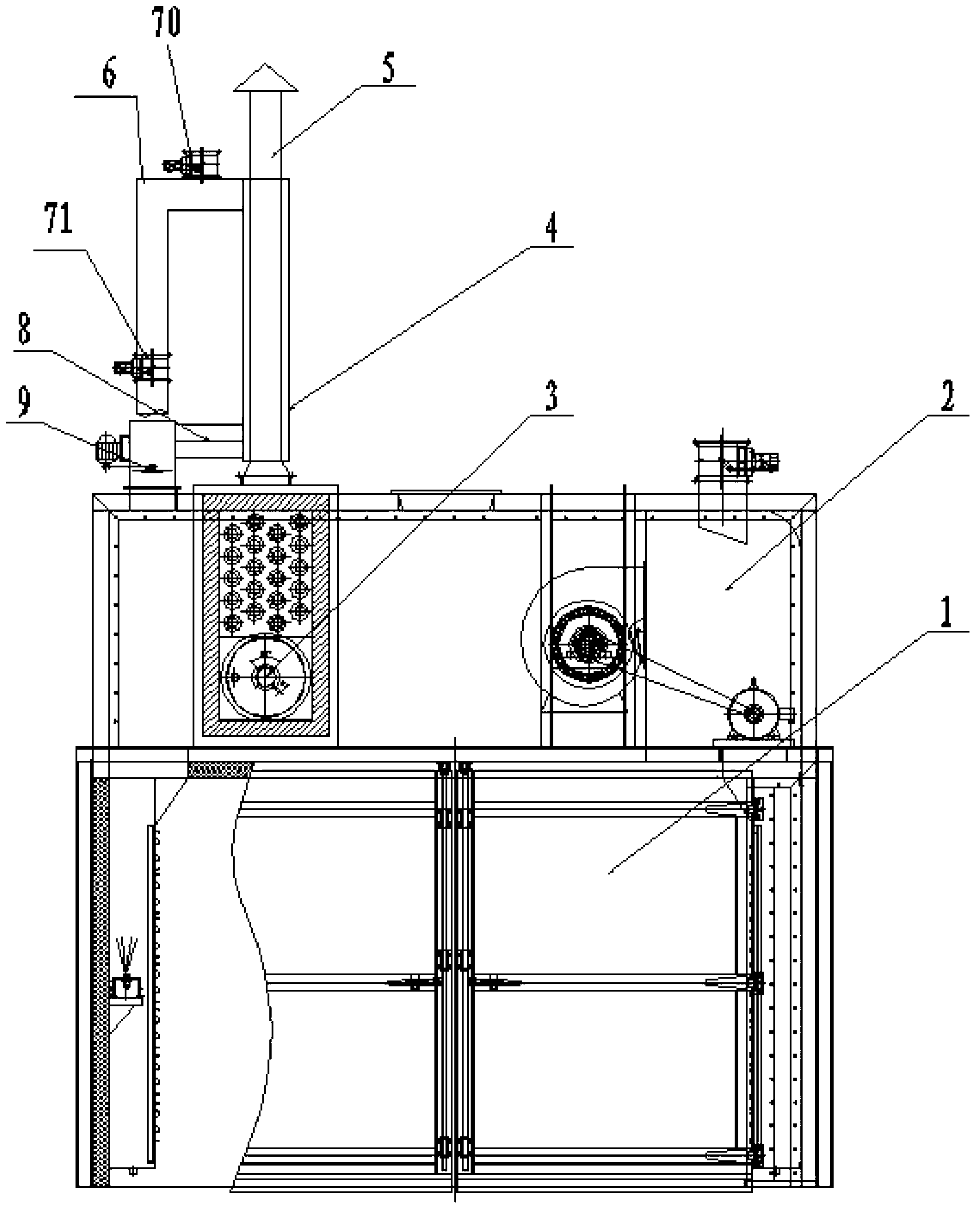

[0018] The present invention will be further described below in conjunction with accompanying drawing.

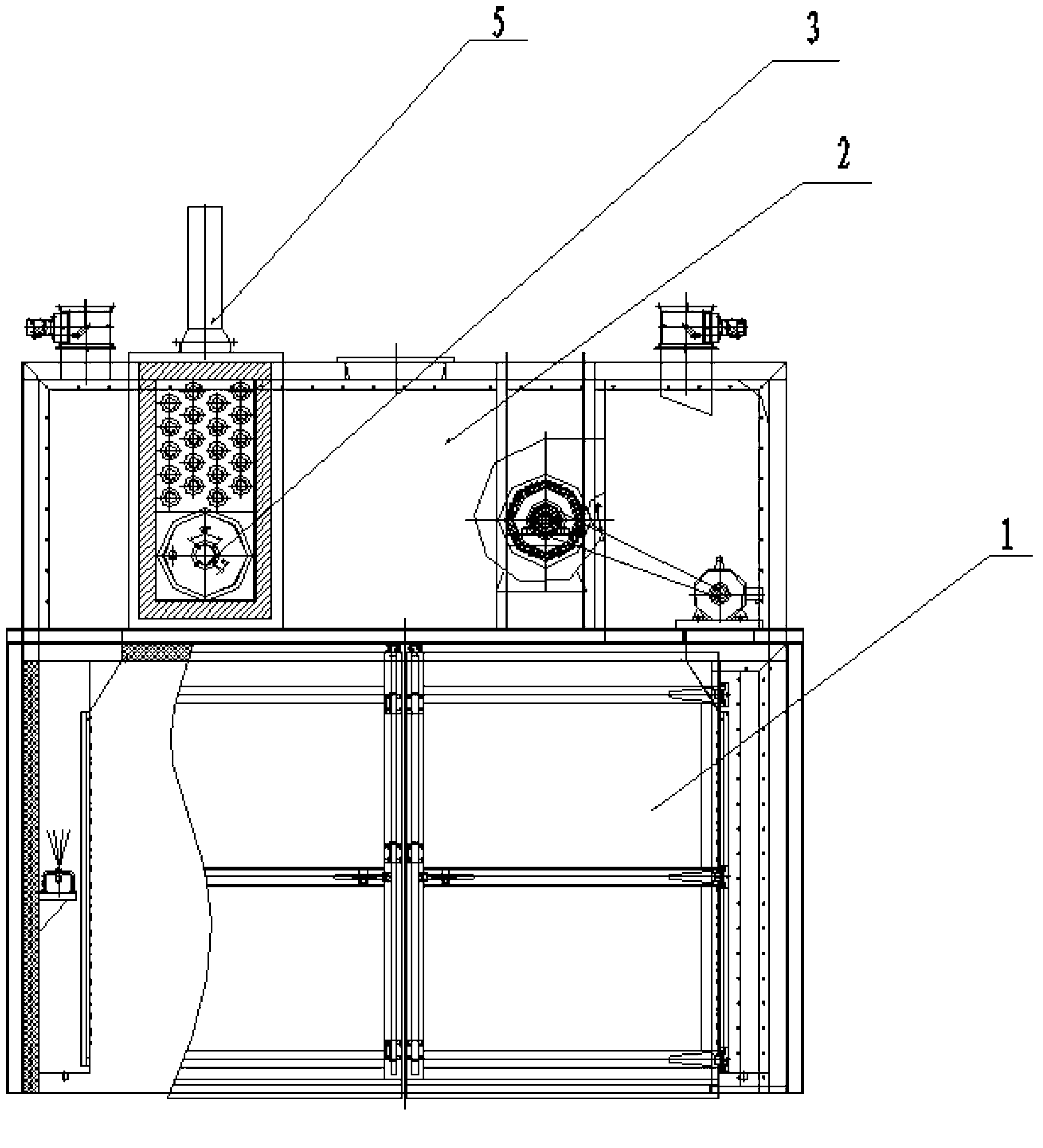

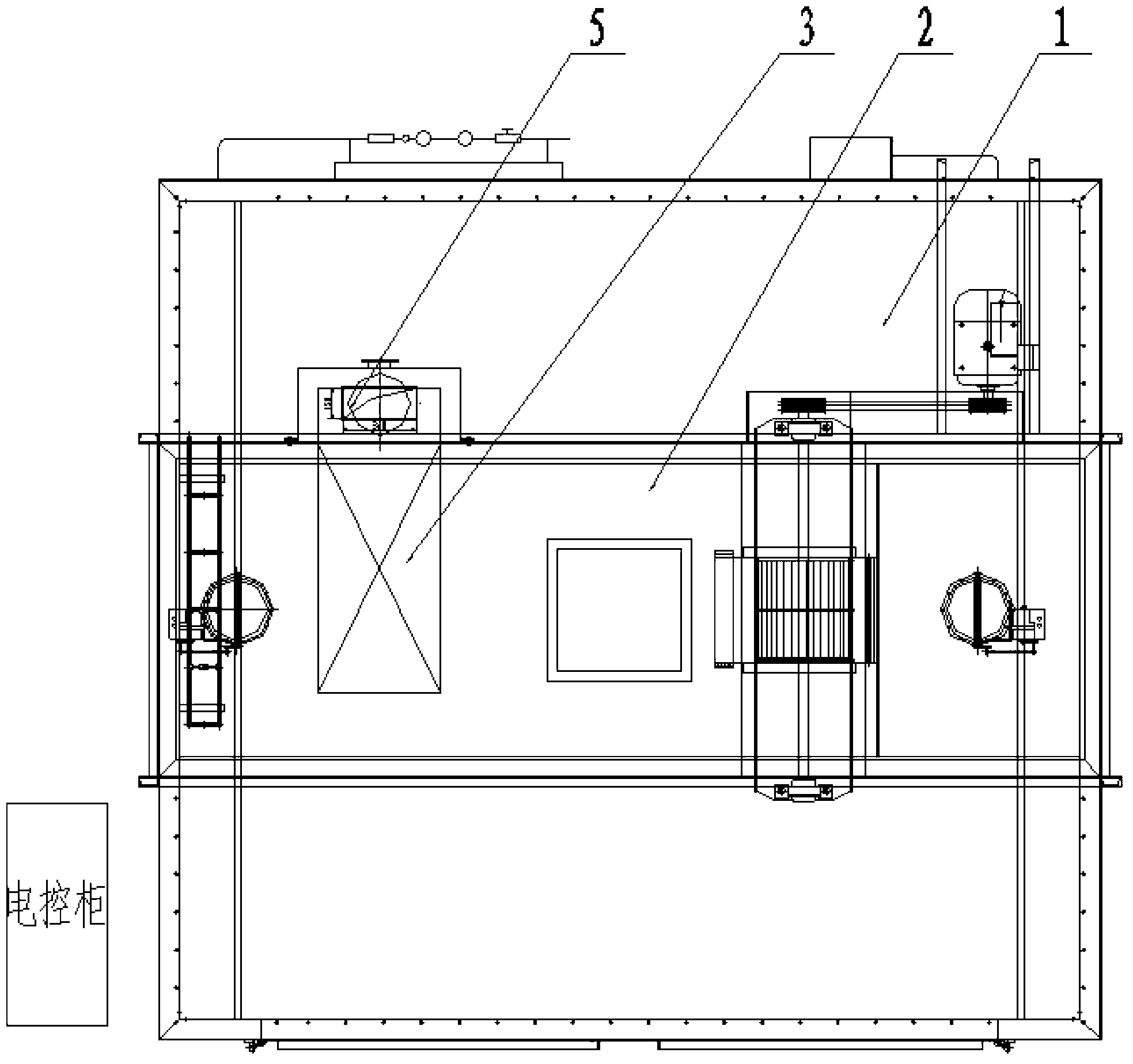

[0019] like Figures 3 to 4 As shown, a heat recovery device is mainly composed of a main box 1, an auxiliary box 2, a burner 3, a burner exhaust pipe 5, a heat recovery device 4, an air inlet pipe 6, and The upper pneumatic valve 70, the lower pneumatic valve 71, the air outlet pipe 8 and the mixed flow fan 9, the exhaust pipe 5 of the burner connected to the burner 3 is provided with a heat recovery device 4, and the upper part of the heat recovery device 4 has an air inlet pipe 6. The air inlet pipe 6 is connected to the main box body 1. An upper pneumatic valve 70 is installed on the upper part of the air inlet pipe 6 to allow natural wind to enter. The lower part of the air inlet pipe 6 is equipped with a lower pneumatic valve 71 to allow circulation air to enter; heat recovery The bottom of device 4 is equipped with air outlet pipe 8, and air outlet pipe 8 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap