A kind of widening structure of flexible packaging lithium-ion battery and its manufacturing method

A production method, lithium ion technology, applied in the direction of structural parts, electrolyte storage battery manufacturing, circuits, etc., can solve problems such as poor fixation, no better improvement of battery cell fixing methods, and hot melt adhesive can not be effectively filled, etc., to achieve improvement Effect of Width Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the implementation of the present invention is not limited thereto.

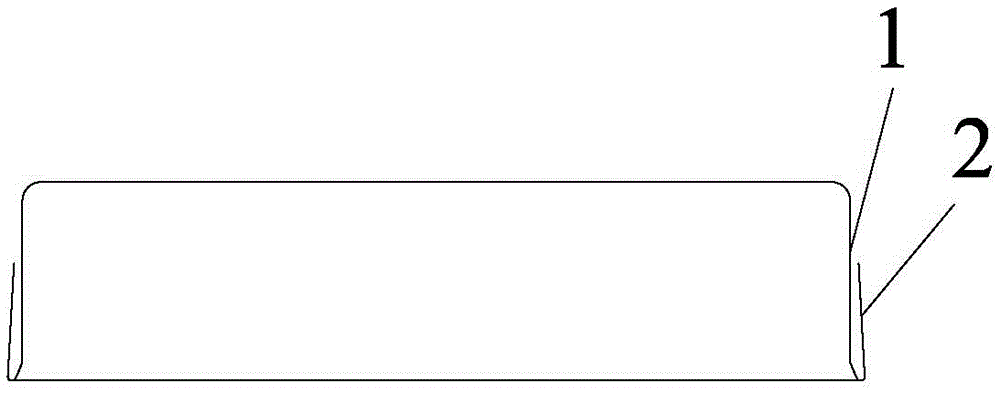

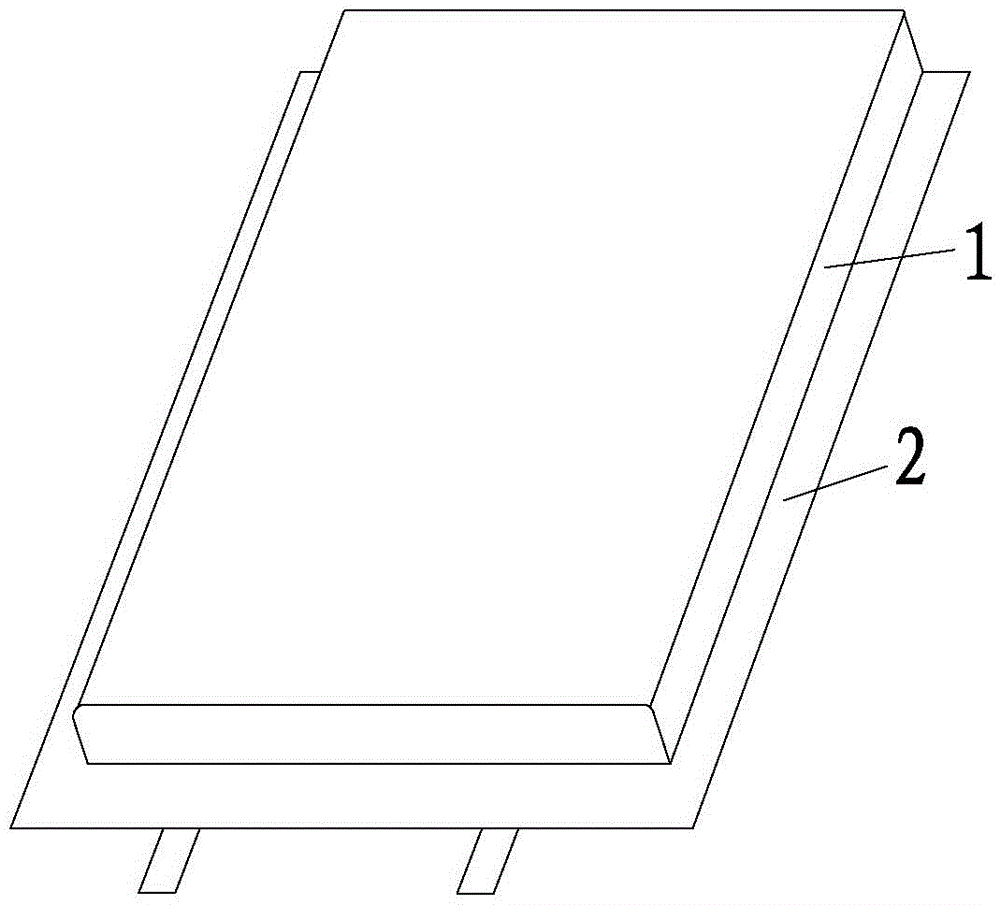

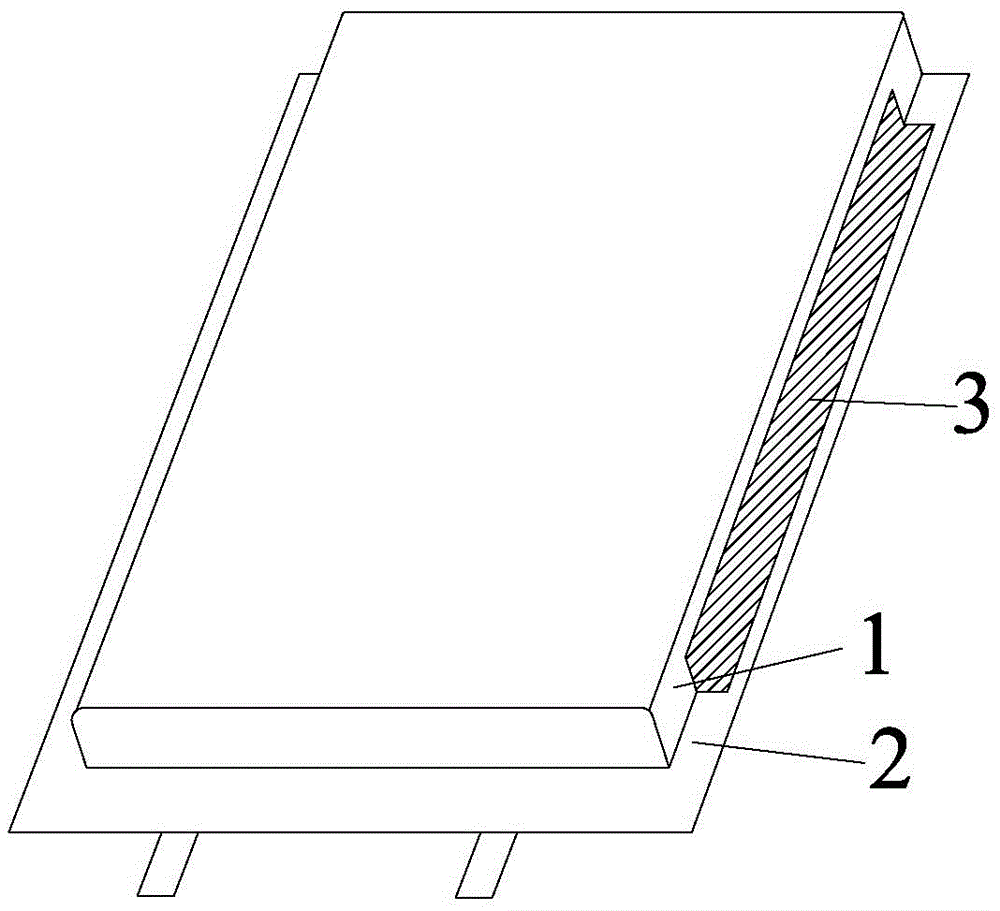

[0028] like Figure 2~6 As shown, a flexible packaged lithium-ion battery cell widening structure, including the cell main body side 1 and the packaging fold 2 located on both sides of the battery main body side 1, between the battery main body side 1 and the packaging fold 2 A widened area 4 is provided, and a filler 3 is arranged in the widened area 4, one side of the filler 3 is bonded to the side 1 of the main body of the battery cell, and one side of the filler 3 is bonded to the package fold 2 or One side of the filler 3 is bonded to the side 1 of the main body of the battery cell, and the other side of the filler 3 is bonded to the package fold 2 .

[0029] Preferably, the filler 3 includes at least one of double-sided adhesive tape, crepe adhesive tape and DuPont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com