Industrially-used glue-applying device

A gluing device, an industrial technology, applied in the direction of the surface coating liquid device, coating, etc., to achieve the effect of good width consistency, saving glue, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

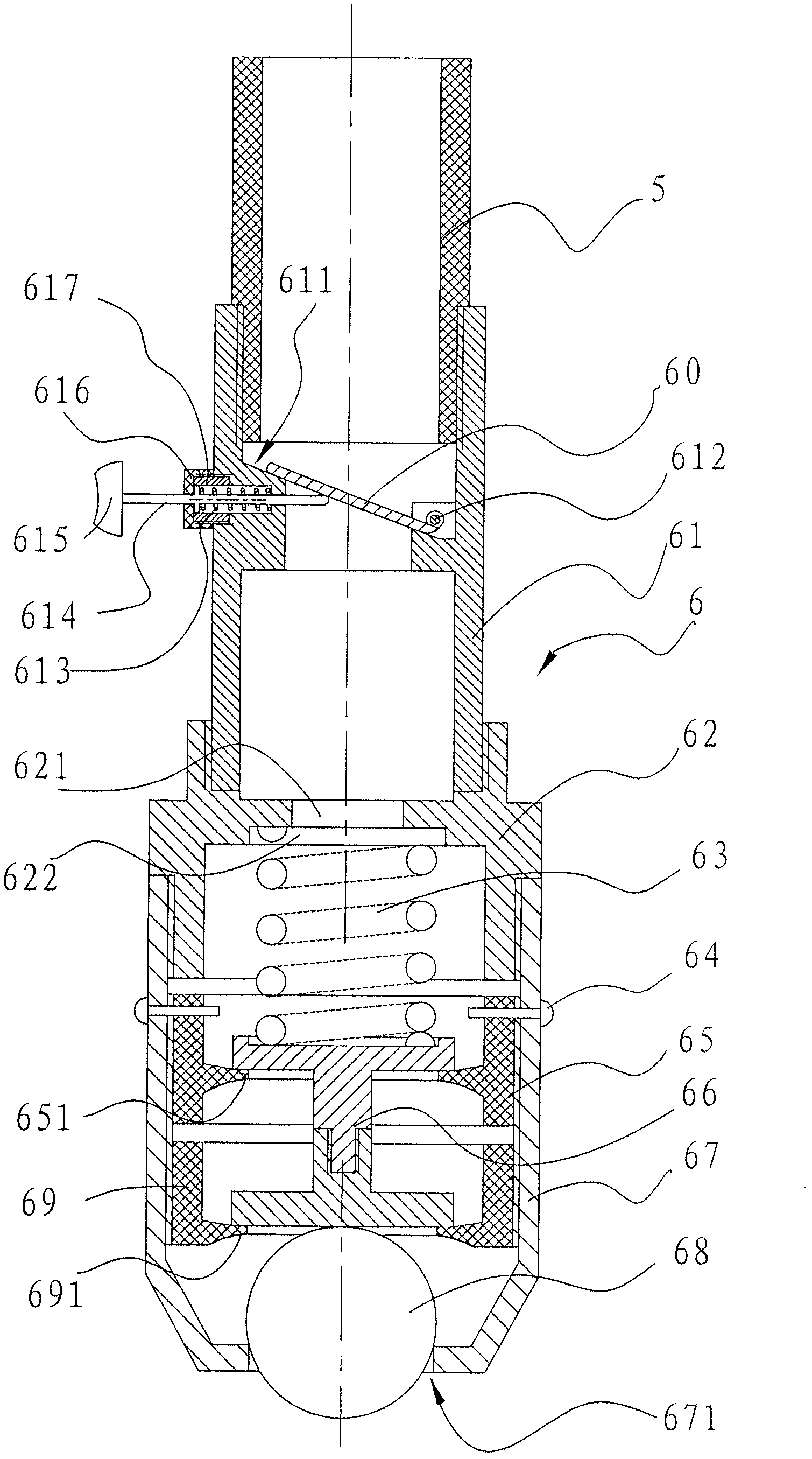

[0019] The upper end of the spring seat 62 has a through hole 621 and is threaded with the main valve 61, and the lower end is threaded with the glue outlet 67; the glue outlet 671 is opened at the bottom of the glue outlet 67, and rolling balls are arranged in the glue outlet from bottom to top. 68. Top block 66, coil spring one 63, the upper end of coil spring one is in contact with spring seat one 62, the lower end is in contact with top block 66, the diameter of glue outlet 671 is slightly smaller than the diameter of rolling ball 68, so that the rolling ball is limited to In the glue outlet.

[0020] In order to increase the frictional force of the rolling ball on the adherend, the surface of the rolling ball is made into an uneven shape, for example, the surface of the rolling ball is made with densely distributed protrusions. In this embodiment, the surface of the rolling ball 68 has a plurality of grooves intersected by latitude and longitude to form unevenness, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com