Construction device for weak current engineering wiring

A technology of weak current engineering and construction equipment, which is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low cutting efficiency, affecting the quality of wiring, and difficult to remove, so as to improve efficiency and quality, improve management performance, reduce Affects the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

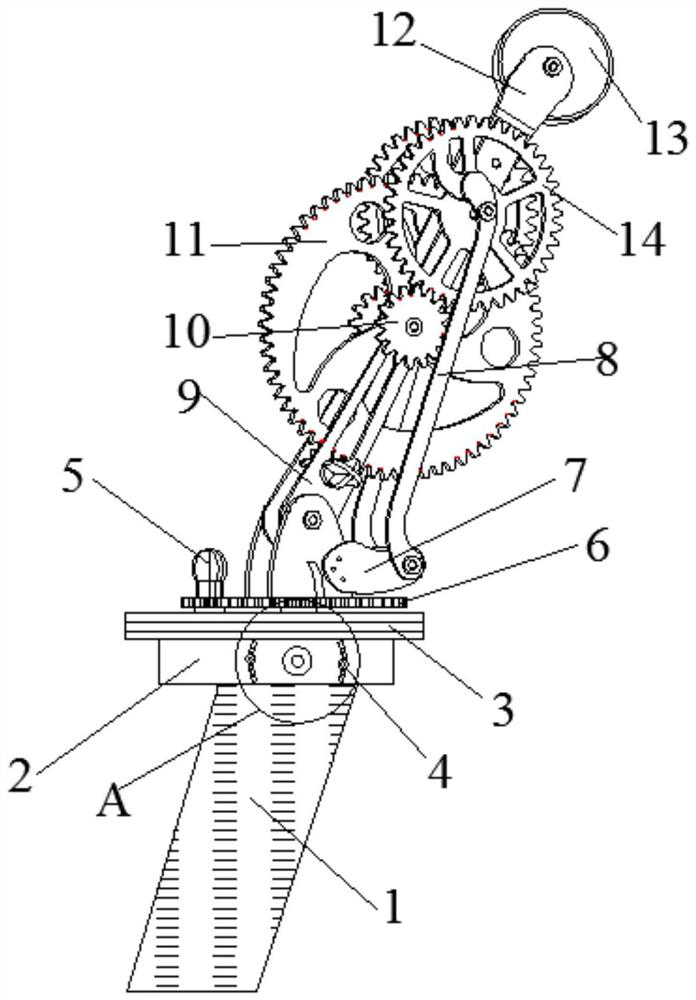

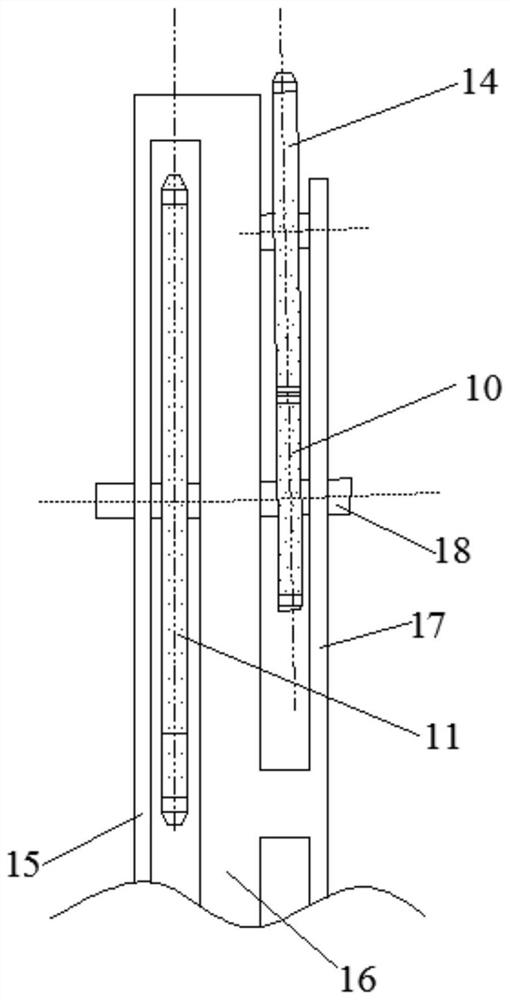

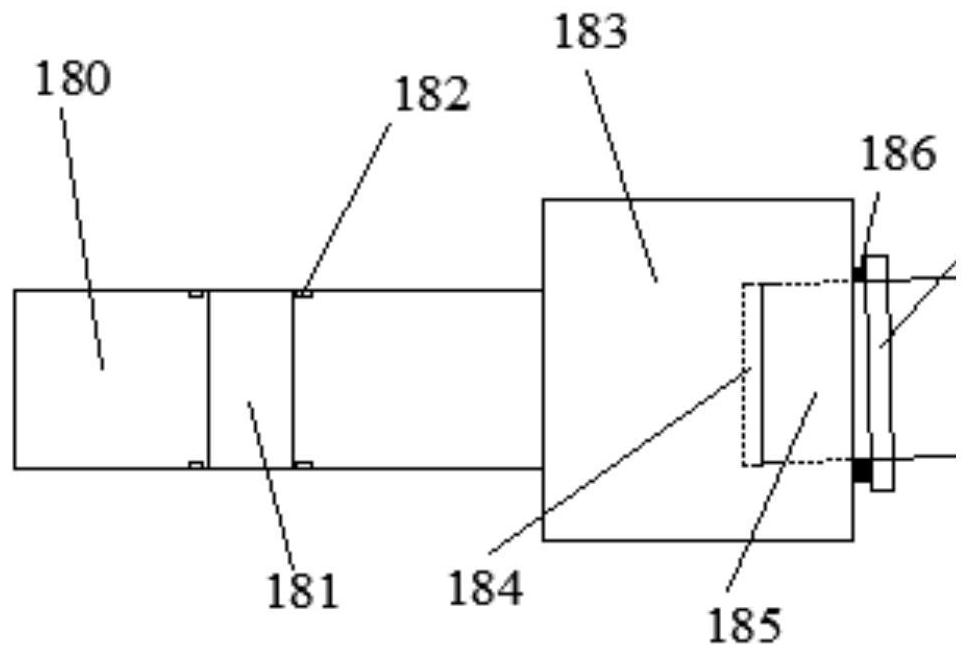

[0021] see Figure 1~4 , in an embodiment of the present invention, a construction device for weak current engineering wiring, which includes an operating handle 1, a fixed base 2, a rotating disk assembly, a mounting frame mechanism 9, a first cutting saw 11, two second cutting saws 14 and auxiliary The traveling assembly, wherein the bottom of the fixed base is provided with the operating handle 1 which can adjust the angle, and the upper end surface of the fixed base is fixedly supported by the rotating disk assembly and provided with the installation frame mechanism 9, which is characterized in that , the mounting frame mechanism can achieve rotation adjustment through the rotating disk assembly, the mounting frame mechanism is provided with the first cutting saw driven to rotate by a drive motor, and the two sides of the first cutting saw are symmetrically arranged There is a second cutting saw, and the first cutting saw and the second cutting saw are not coaxially arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com