Shape pressing die of wall board of motor tractor

A technology of pressing dies and tractors, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as uneven force, non-coincidence of parts centers and mold centers, and failure to meet design requirements, so as to prevent accidents Wrinkle phenomenon, slow down the forming speed, improve the effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

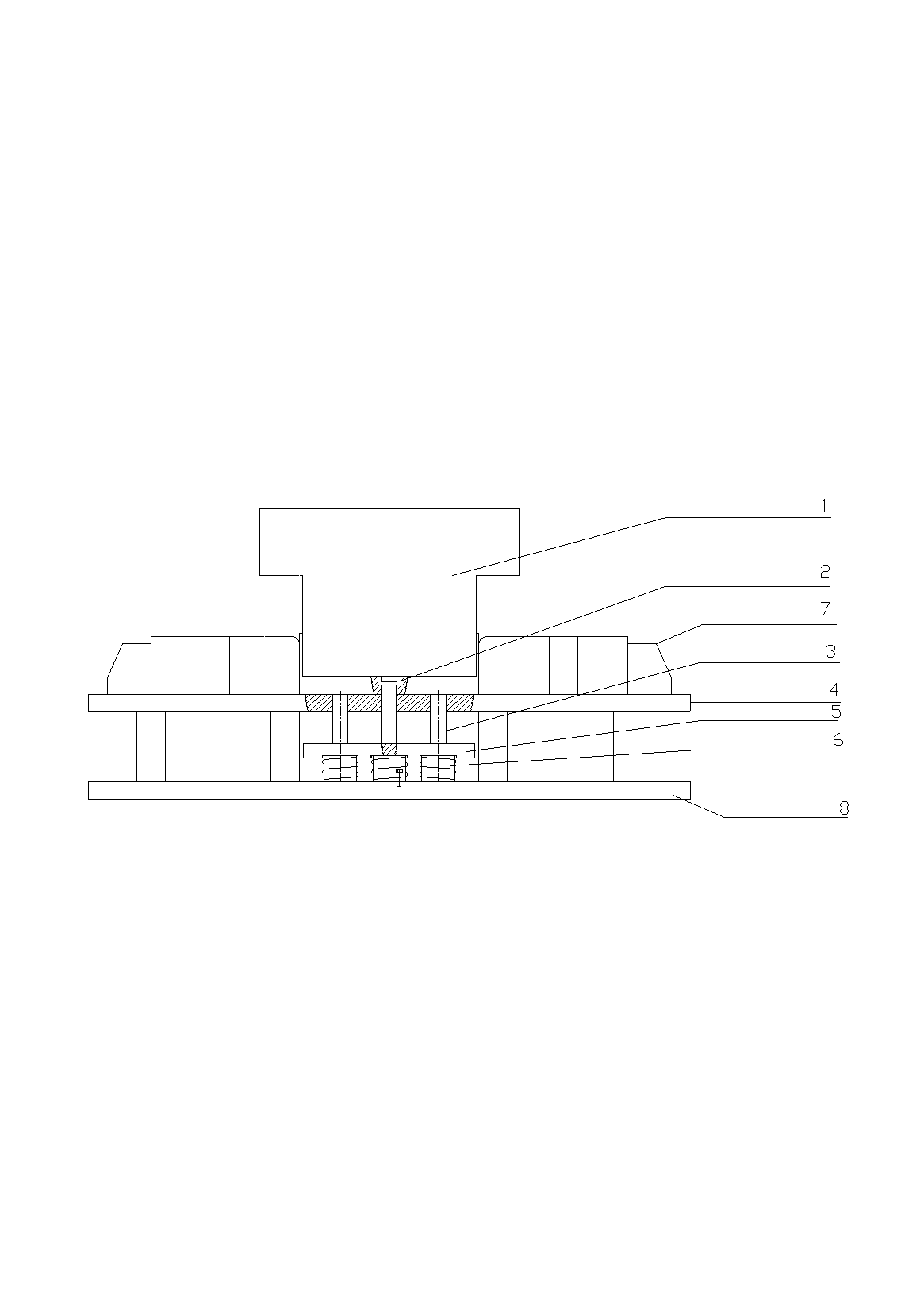

[0008] like figure 1 As shown, the present invention includes a die structure 7, a punch 1, and the die structure 7 includes a die 4, a die base 8, and a support plate 5 is arranged between the die 4 and the die base 8, and the support plate 5 is provided with a guide post 3 and a ejector rod 2, there are two guide posts 3, the ejector rod 2 is arranged between the two guide posts 3, and a spring 6 is pressed between the support plate 5 and the die base 8 .

[0009] The punch 1 goes down, the workpiece contacts the ejector rod 2, the spring 6 is compressed by the external force, and the rebound force of the spring 6 acts on the die 4, so that the die 4 contacts the workpiece smoothly and slowly, slowing down the forming speed of the workpiece. During the forming process, its periphery always maintains a continuous and uniform pressing force, which effectively prevents the wrinkling phenomenon, improves the appearance quality of the workpiece, and makes it meet the design requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com