Method for adjusting supercharging conversion rotation speed of aero engine

An aero-engine and adjustment method technology, applied in the field of aero-engines, can solve the problems of repeated engine testing, increase production costs, and insignificant effects, and achieve the effects of improving the qualification rate of testing, saving production costs, and reducing testing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

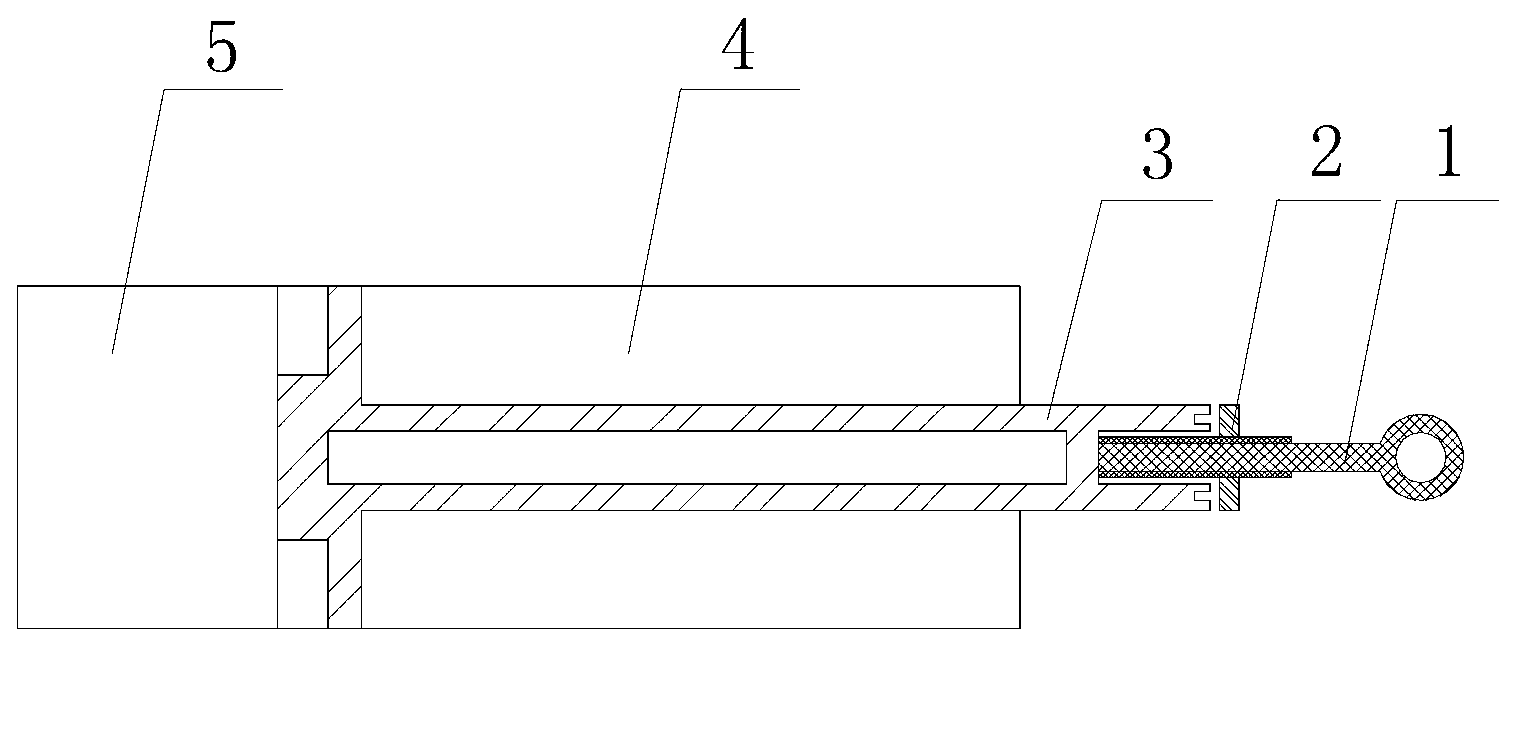

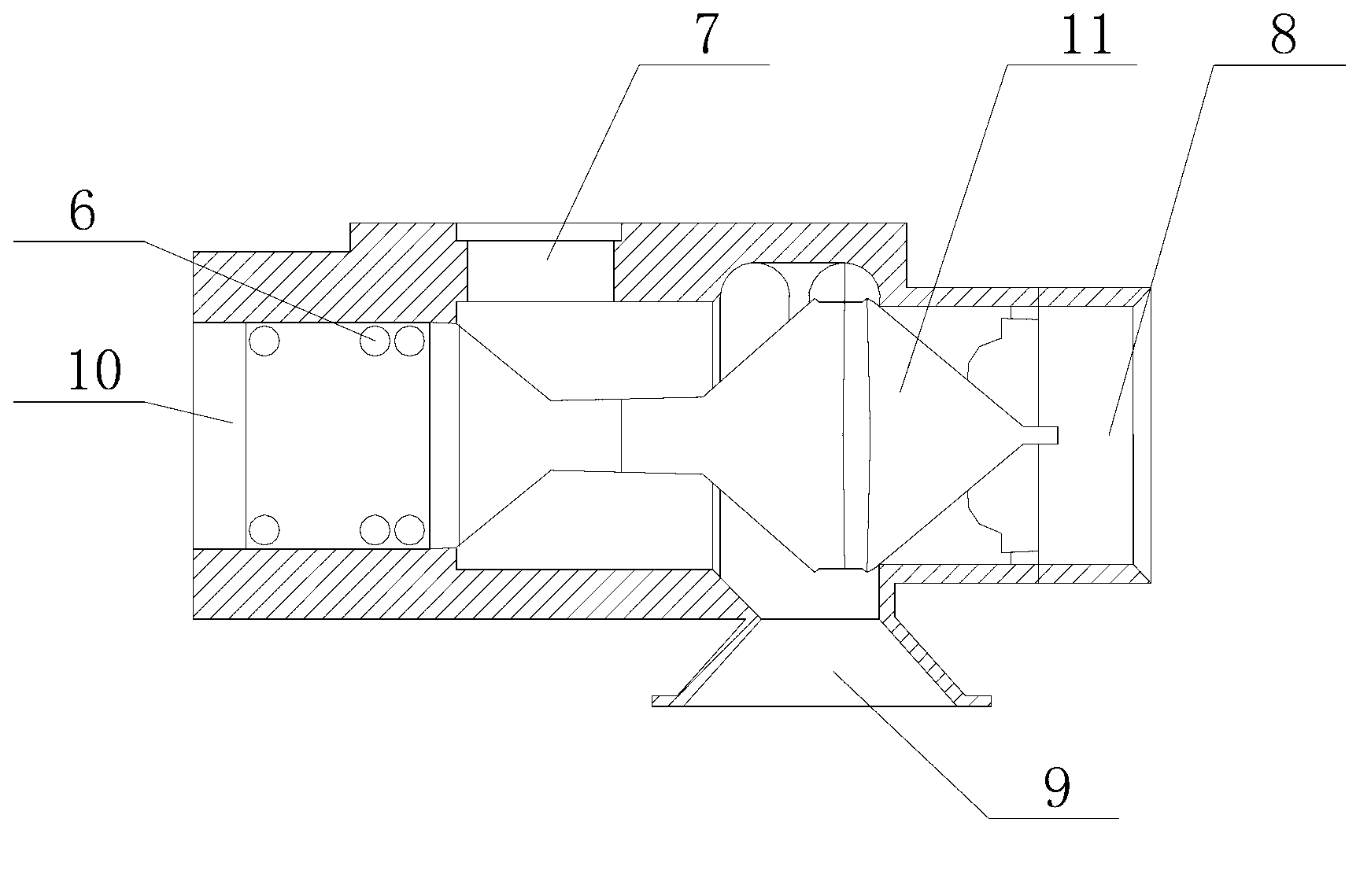

[0037] Such as figure 1 As shown, an aero-engine supercharging conversion speed adjustment method specifically includes the following steps:

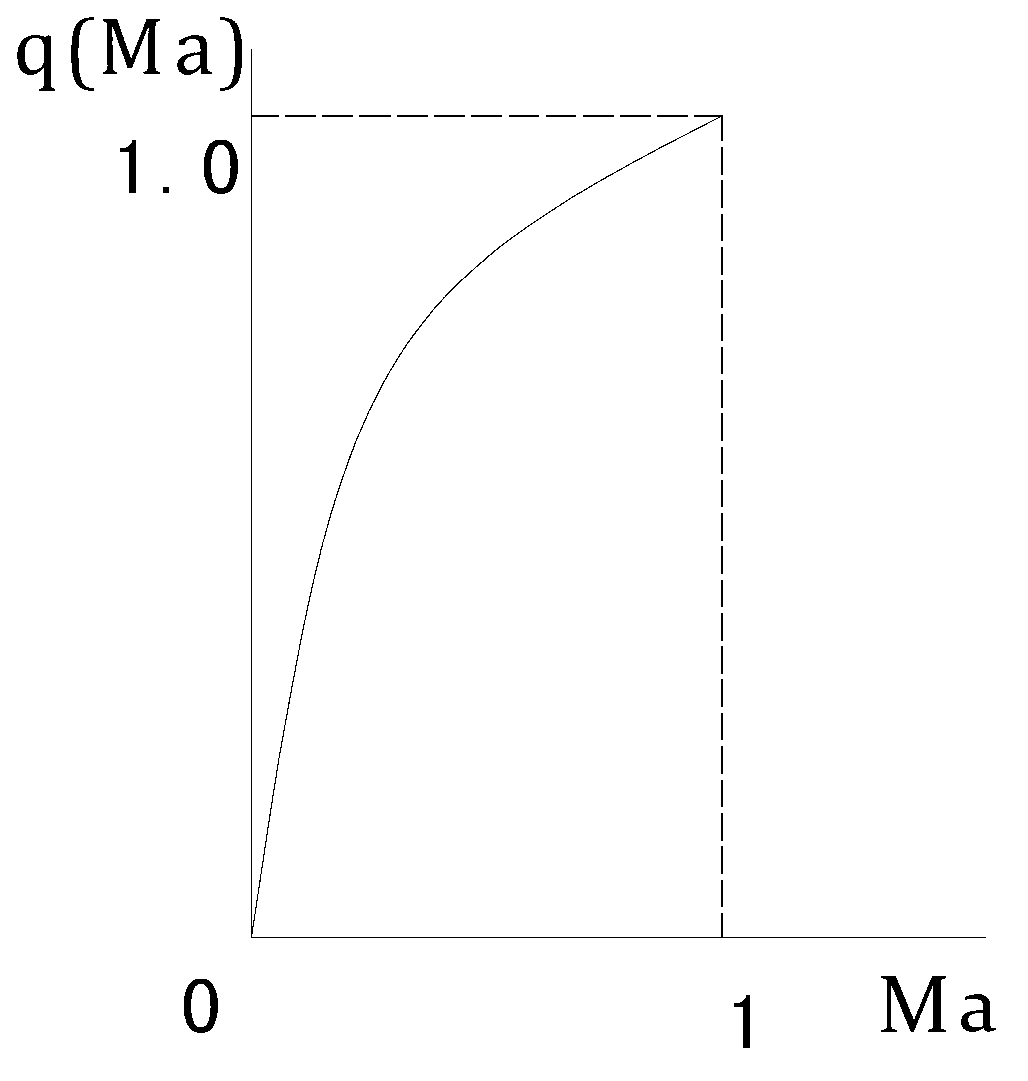

[0038] Step 1: The ideal switching speed range of the supercharging switching valve required by the engine is 88-90%, and the actual switching speed is 94%, and the actual switching speed range of the supercharging switching valve is larger than the ideal switching speed range;

[0039] Step 2: Use the hydraulic cylinder piston rod 3 to reduce the diameter of the engine tail nozzle until the actual switching speed of the supercharging switching valve is adjusted to the ideal switching speed range.

[0040] The method for adjusting the diameter of the engine tail nozzle through the hydraulic cylinder piston rod 3 specifically includes the following steps:

[0041] Step A: Increase the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com