Method and structure for cleaning water vapor system of Shell gasification furnace

A gasifier and water vapor technology, which is applied to the cleaning and cleaning of the water vapor system of Shell gasifiers, can solve the problems of inability to flush out large-sized sundries, increase costs, time, and equipment damage, and achieve extended use. life, save cleaning time and cost, improve heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the invention:

[0016] Shell gasifier water vapor system cleaning method includes the following processes:

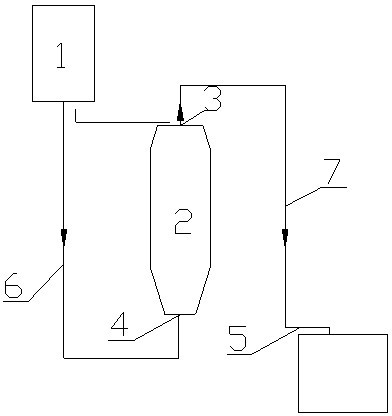

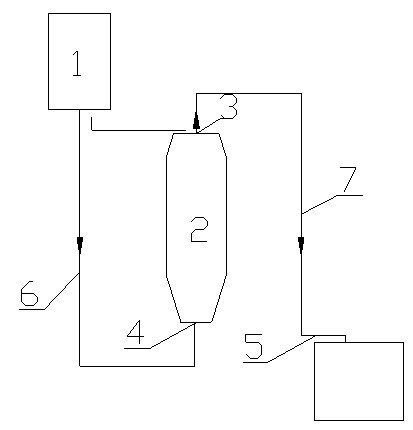

[0017] a. Fill the steam drum 1 of the water vapor system of the Shell gasifier until the water level in the steam drum 1 accounts for more than 80% of the total volume;

[0018] b. Use the temporary water inlet pipe 6 to connect the outlet pipe of the steam drum 1 to the cooling water outlet 4 of the gasification furnace 2, and use the temporary water outlet pipe 7 to connect the cooling water inlet 3 of the gasification furnace 2 to the cooling water drain pipe 5 ; Use high-pressure nitrogen to pressurize the steam drum to 0.7 to 0.8MPa.

[0019] c. Open the valve of the steam drum 1, so that the water in the steam drum 1 flows in from the condensed water outlet 4 of the gasifier 2, and flows out from the condensed water inlet 3 of the gasifier 2, realizing reverse flushing;

[0020] d. After the flushing is completed, remove the temporary wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com