Glasses Elastic Hinge

An elastic hinge and hinge technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of loss of elasticity of glasses feet, high processing cost, poor stability, etc., and achieve good anti-swing effect, high degree of firmness, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

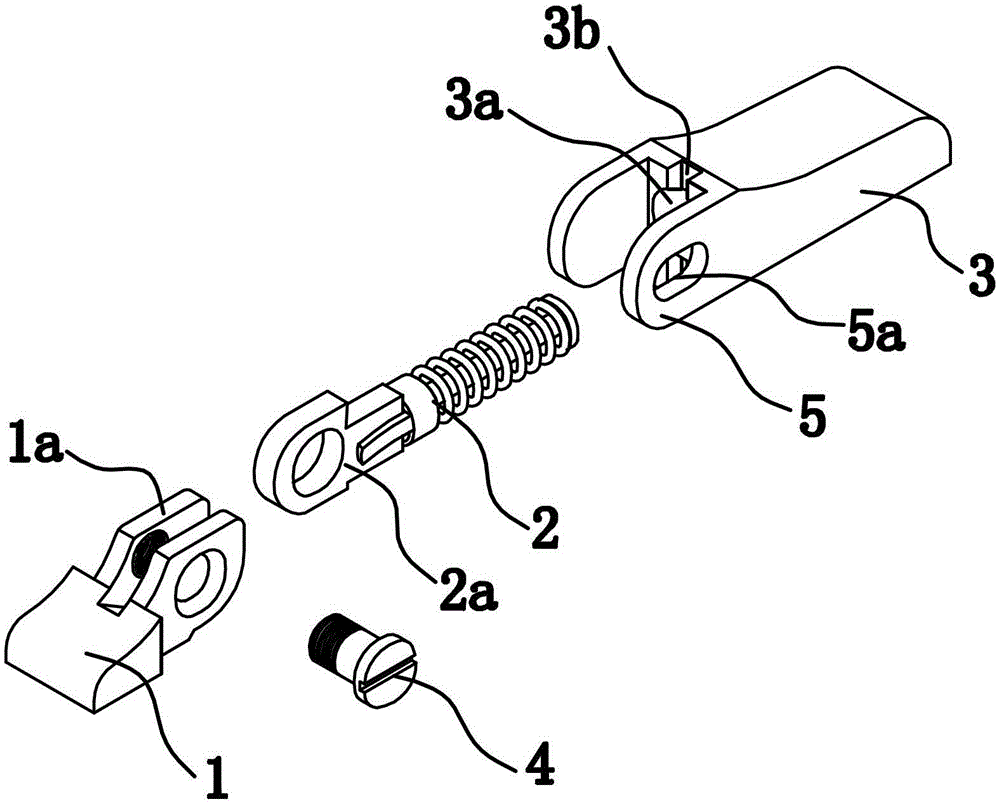

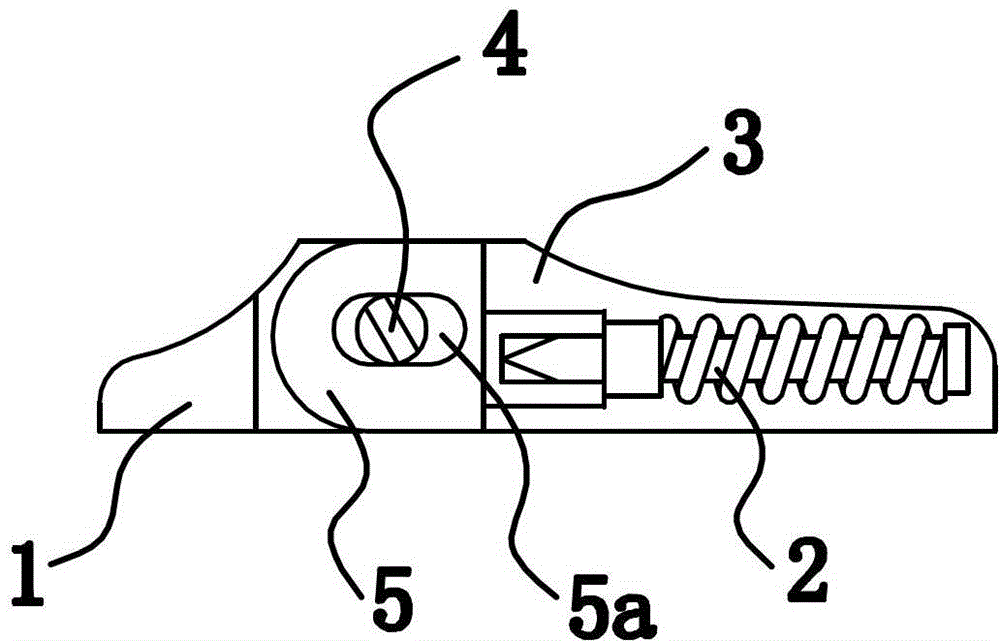

[0042] The glasses elastic hinge provided by the present invention is used for connecting glasses feet and glasses frames, such as figure 1 As shown, it includes a hinge head 1, a spring core 2, a slingshot shell 3 and a pin shaft 4.

[0043] The hinge head 1 is fixedly connected with the spectacle frame, the slingshot case 3 is fixedly connected with the spectacle feet, the spring core 2 is installed in the installation hole 3a of the slingshot case 3, and one end is the hinged end 2a located outside the installation hole 3a, the hinged end 2a It has a hinge hole for hinged connection with the hinge head 1. The slingshot shell 3 has a groove 3b that runs through the slingshot shell 3 up and down along the radial direction of the spring core 2 at the end face of one end of the mounting hole 3a, which is used for inserting inserts when hinged to facilitate the pulling out of the spring core 2. The slingshot shell 3 has two sheet-shaped single-teeth 5 parallel to the axial dire...

Embodiment 2

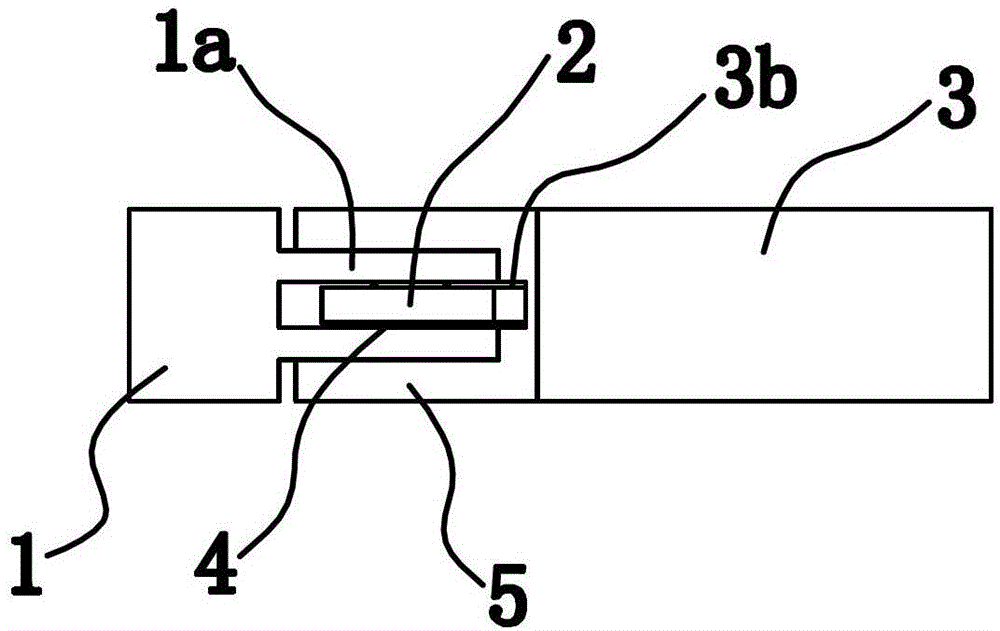

[0047] Such as Figure 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the number of single teeth 5 in this embodiment is one piece, and the inner surface of the single tooth 5 and the outer side of one side of the hinge head 1 Face to face.

Embodiment 3

[0049] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, except that each of the two single teeth 5 in this embodiment has a through hole 5a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com