lubricant distributor

A lubricating oil distributor and lubricating oil technology, applied in the direction of distribution devices, lubricating parts, engine lubrication, etc., can solve the problems of high cost, monitoring pipeline rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

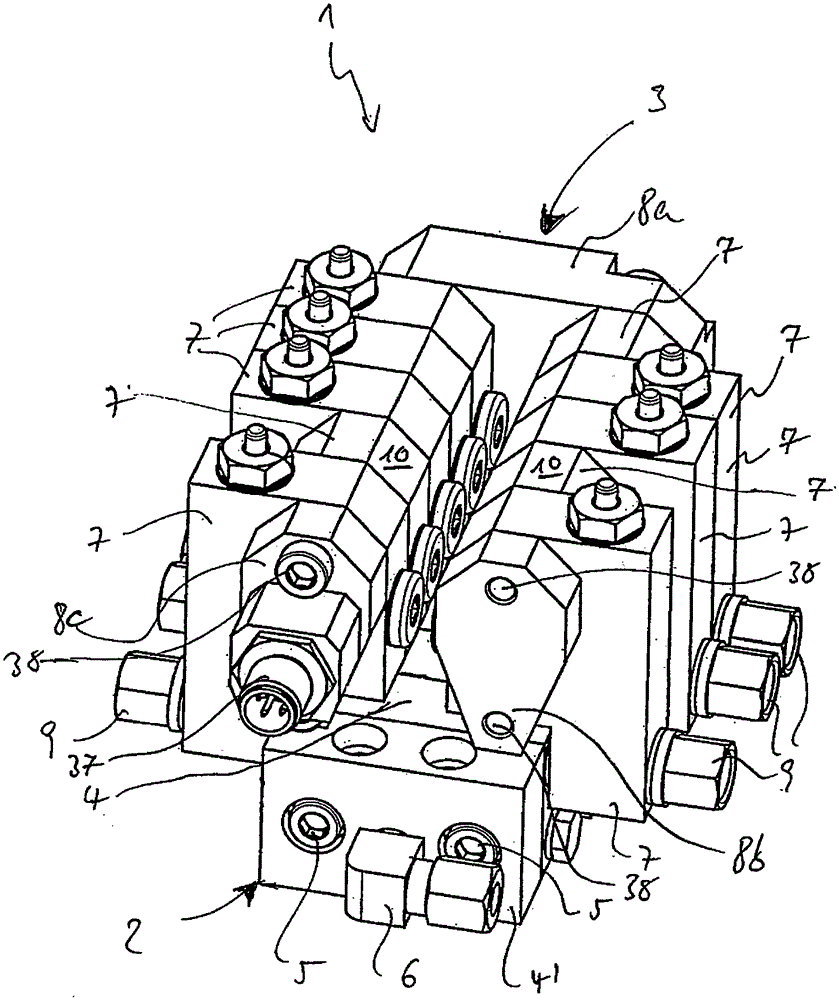

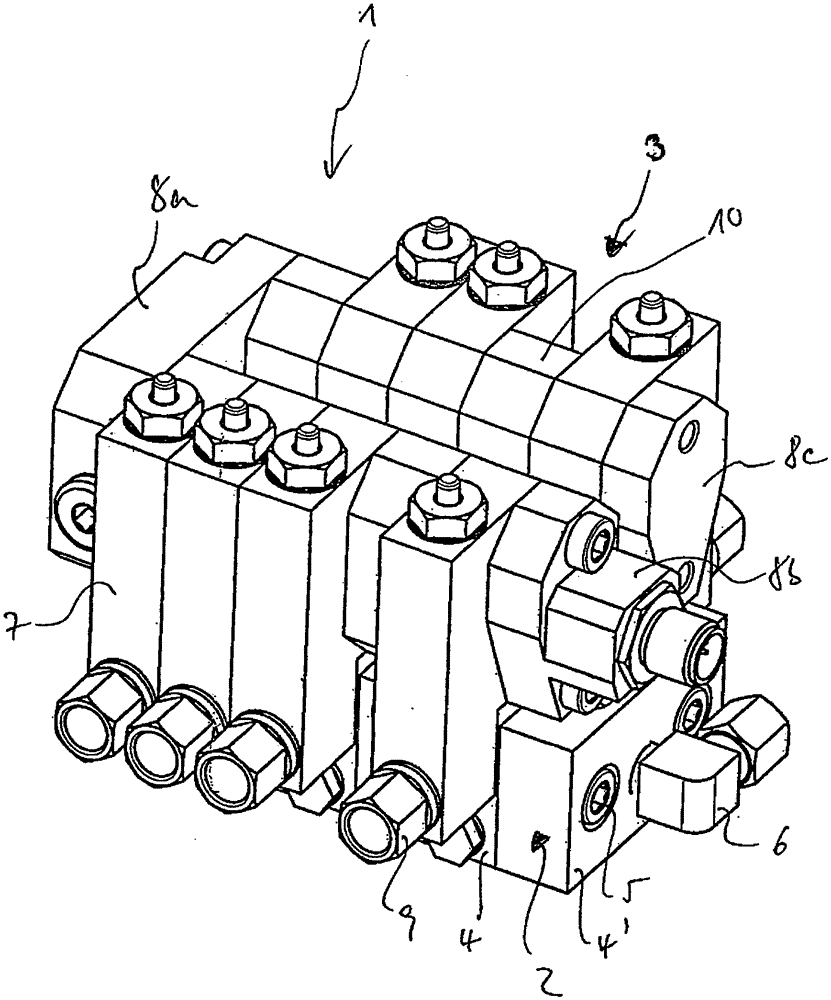

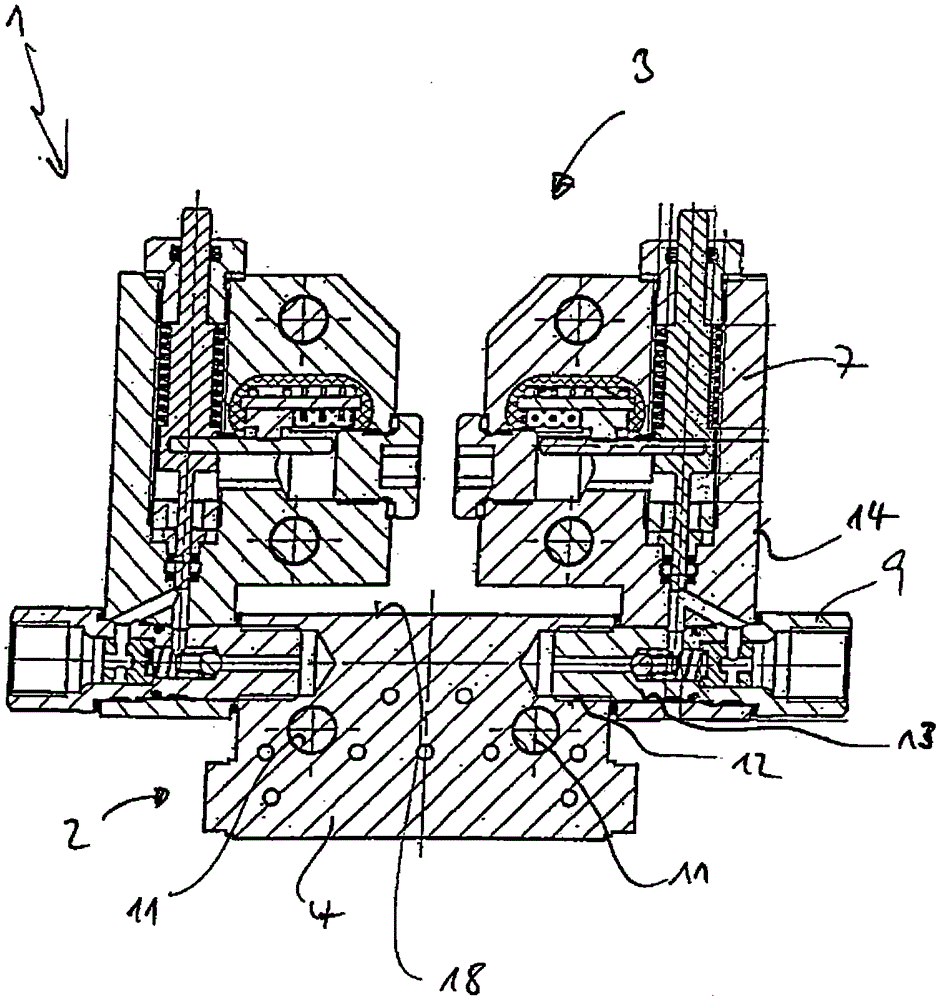

[0023] attached figure 1 A perspective view of the lubricating oil distributor 1 of the present invention is shown. The lubricating oil distributor 1 includes a main distributor 2 and a pipeline rupture monitor 3 . The main dispenser 2 can be, for example, a known progressive dispenser, but in principle the main dispenser 2 can have any desired configuration. The main distributor 2 includes a plurality of distributor outlets, which are not shown in this figure, and the fluid (especially lubricating oil) is transported from these distributor outlets to the positions requiring lubricating oil through corresponding pipelines. The tubing is also not shown in this figure.

[0024] in the attached figure 1 Among them, as an example only, the main distributor 2 has a modular construction, that is to say, the main distributor 2 includes a plurality of main distributor modules 4, which are connected to each other by connecting parts 5 (especially connected by hexagon socket head bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap