Anti-freezing heat exchange device

A heat exchange device, heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of equipment heat exchange efficiency decline, aggravate the increase of heat exchanger costs, and increase operating costs and other problems to achieve the effect of enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

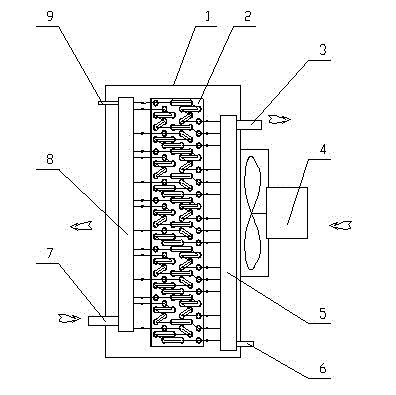

[0012] See figure 1 , an antifreeze heat exchange device, comprising a box body 1, a heat exchanger core body 2 arranged in the box body 1 with a fin-covered copper tube structure, and an inlet connected to the copper tube water inlet end of the heat exchanger core body 2 The water flute tube 8 and the water flute tube 5 connected to the water outlet end of the copper pipe of the heat exchanger core 2 are arranged on the box body 1 and are located on the side of the heat exchanger core 2 to blow the fan 4 to the heat dissipation core; the water inlet flute The pipe 8 is provided with a water inlet 7 and an air release valve 9 extending out of the tank 1, and the water inlet 7 is located at the lower end of the water inlet pipe 8, and the air release valve 9 is located at the uppermost end of the water inlet pipe 8 Outlet pipe 5 is provided with water outlet 3 and water discharge valve 6 extending out of the box, and water outlet 3 is located at the uppermost end of water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com