Method for testing rut resistance of multi-layered combined structure mixtures of bituminous pavements

A combined structure and asphalt pavement technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problem that the thickness of the specimen cannot be changed, the multi-layer combination test cannot be performed, and the high-temperature performance of asphalt mixture cannot be evaluated and analyzed, etc. Problems, to achieve the effect of perfect detection and design work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

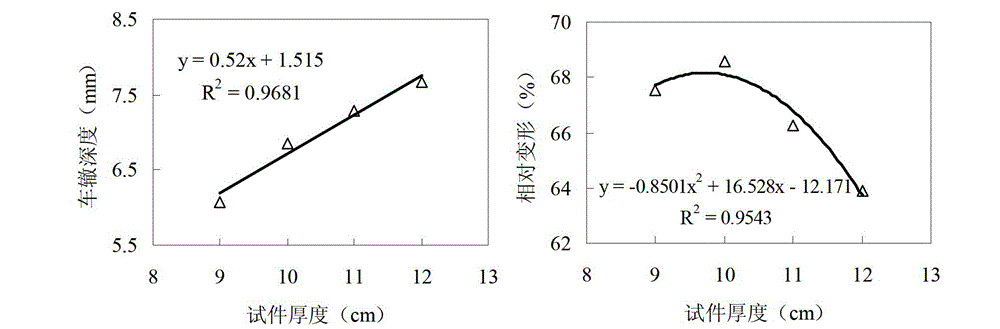

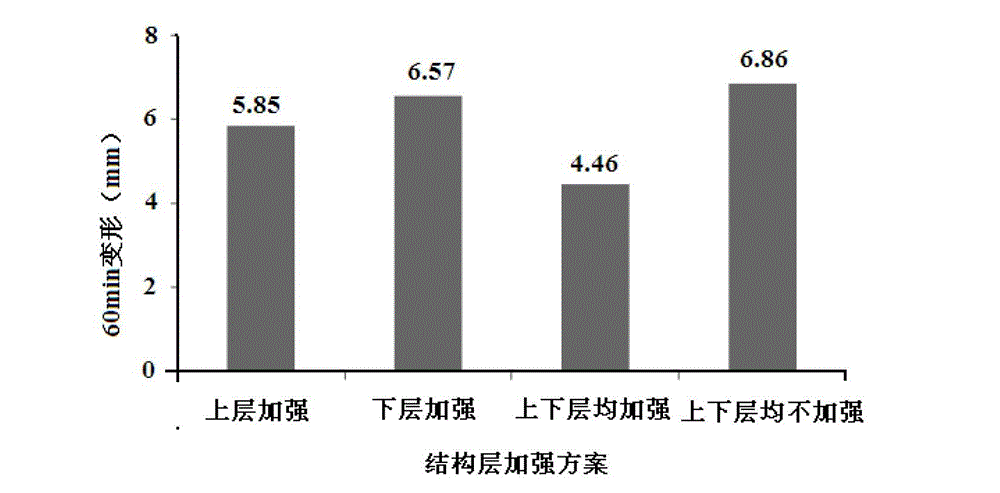

[0072] The structural factors affecting the high-temperature performance of asphalt pavement mainly include the thickness of the asphalt layer, the modulus (strength) ratio of the structural layer, and the contact conditions between layers. According to the above three influencing factors, formulate the composite structure rutting test plan (Table 1), and carry out the asphalt pavement composite structure rutting test:

[0073] Table 1: Composite structure rutting test scheme

[0074]

[0075] The mix of AC-13 and AC-20 asphalt mixtures used in the test is shown in Table 2~Table 3. The asphalt is Esso AH-90 matrix asphalt, the coarse and fine aggregates are limestone, the mineral powder is ground limestone, and various materials The technical indicators are in line with the "Technical Specifications for Highway Asphalt Pavement Construction" (JTG F40-2004).

[0076] Table 2: Design of AC-13 Mixture Proportion

[0077] mesh size

13.2

9.5

4.75

2.36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com