Method, control and/or regulating device, and reversible hot rolling mill for operating coils of a coiler heating furnace of a reversibly operating hot rolling mill

A technology of adjusting device and hot rolling mill, applied in the direction of metal rolling, tension/pressure control, etc., can solve the problems of metal strip pull-out, scratches, reduction of economic value of metal strip, etc., and achieve the effect of less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

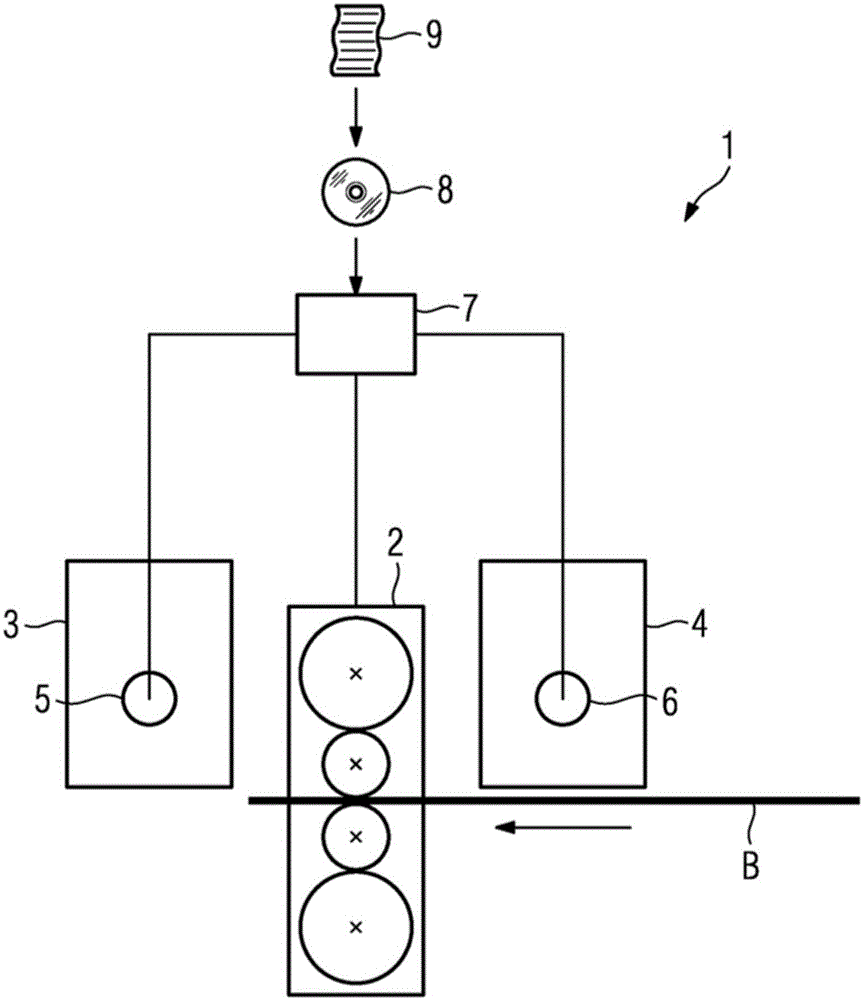

[0028] figure 1 A Stekel rolling mill is schematically shown. The Stekel rolling mill 1 comprises at least one rolling stand 2 for the hot rolling of a rolling stock, in particular a metal strip B. As shown in FIG. It is possible to provide one rolling stand or to provide several rolling stands.

[0029] Adjacent to the last rolling stand in the working direction (alternating due to reversing rolling) a so-called Stekel furnace 3 or 4 is respectively arranged. The Stekel furnace 3 or 4 is used to heat and support the hot rolled stock between two rolling passes.

[0030] For this purpose, each Stekel furnace comprises a reel 5 or 6 respectively, on which the hot strip B is wound up after the rolling pass (under the conditions of the last rolling pass) . For this, the strip B is fed to a Stekel furnace 3 or 4 and clamped into reels.

[0031] The drum 5 or 6 and at least one rolling stand are operatively connected to a control and / or regulating device. In particular, the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com