A reluctance disc motor

A disc motor and reluctance technology, applied to synchronous motors with stationary armatures and rotating magnets, etc., to achieve the effects of short axial size, high motor power density, and simple rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be described in further detail below in conjunction with the accompanying drawings.

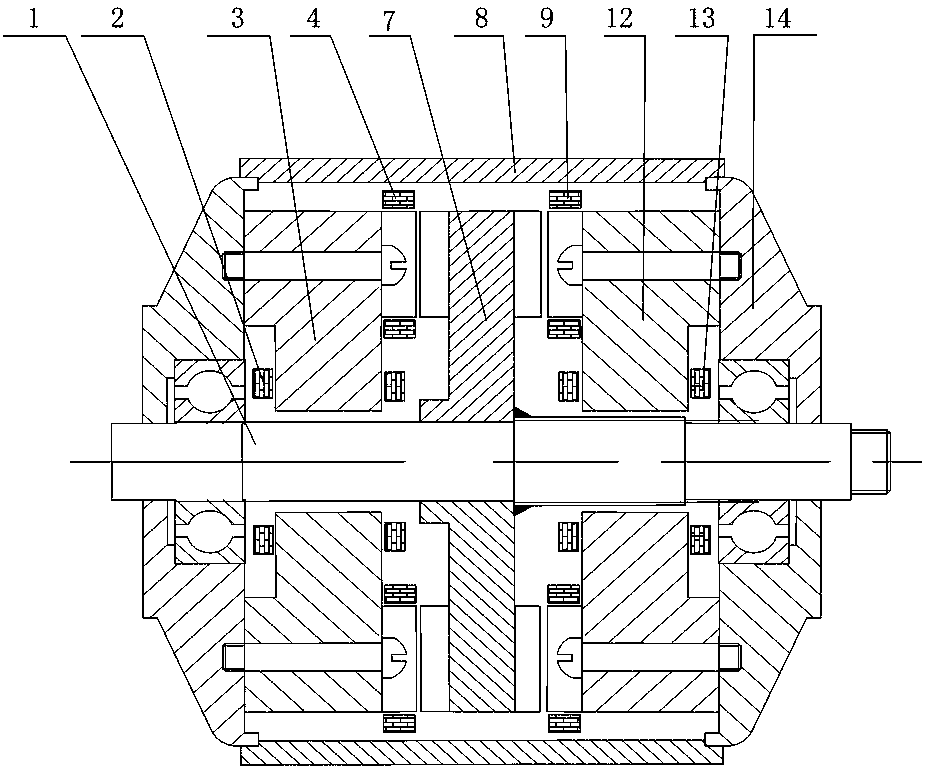

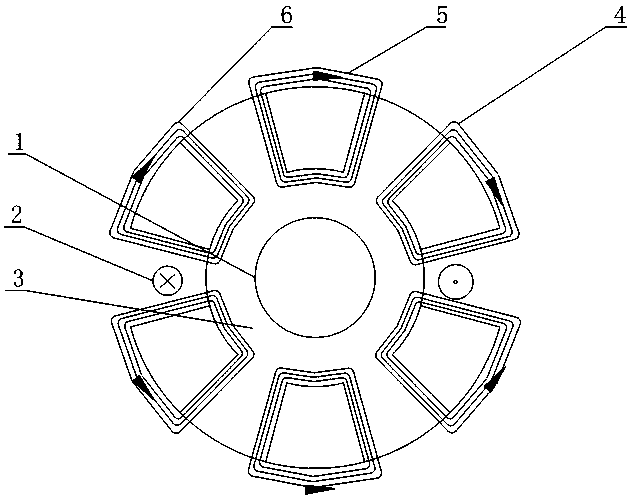

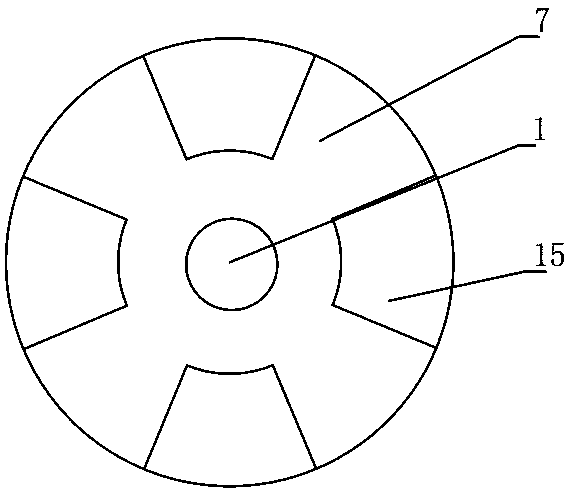

[0029] figure 1 It is a longitudinal sectional view of a reluctance disc motor of the present invention. A reluctance type disc motor shown consists of a shaft (1), a first excitation coil (2), a first stator core (3), a first armature coil, a rotor core (7), and a casing (8 ), the second armature coil (9), the second stator core (12), the second field winding (13) and the end cover (14). The rotor core (7) is disc-shaped and fixed on the shaft (1). The rotor core (7) has 2N circular fan-shaped raised rotor poles on both end faces of the disc; the first stator core ( 3), the axes of the second stator core (12) and the rotor core (7) are the same, the first stator core (3) and the second stator core (12) are respectively located on both sides of the rotor core (7), the first stator On the side opposite to the rotor core (7) of the sub-core (3) there are 3N ring sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com