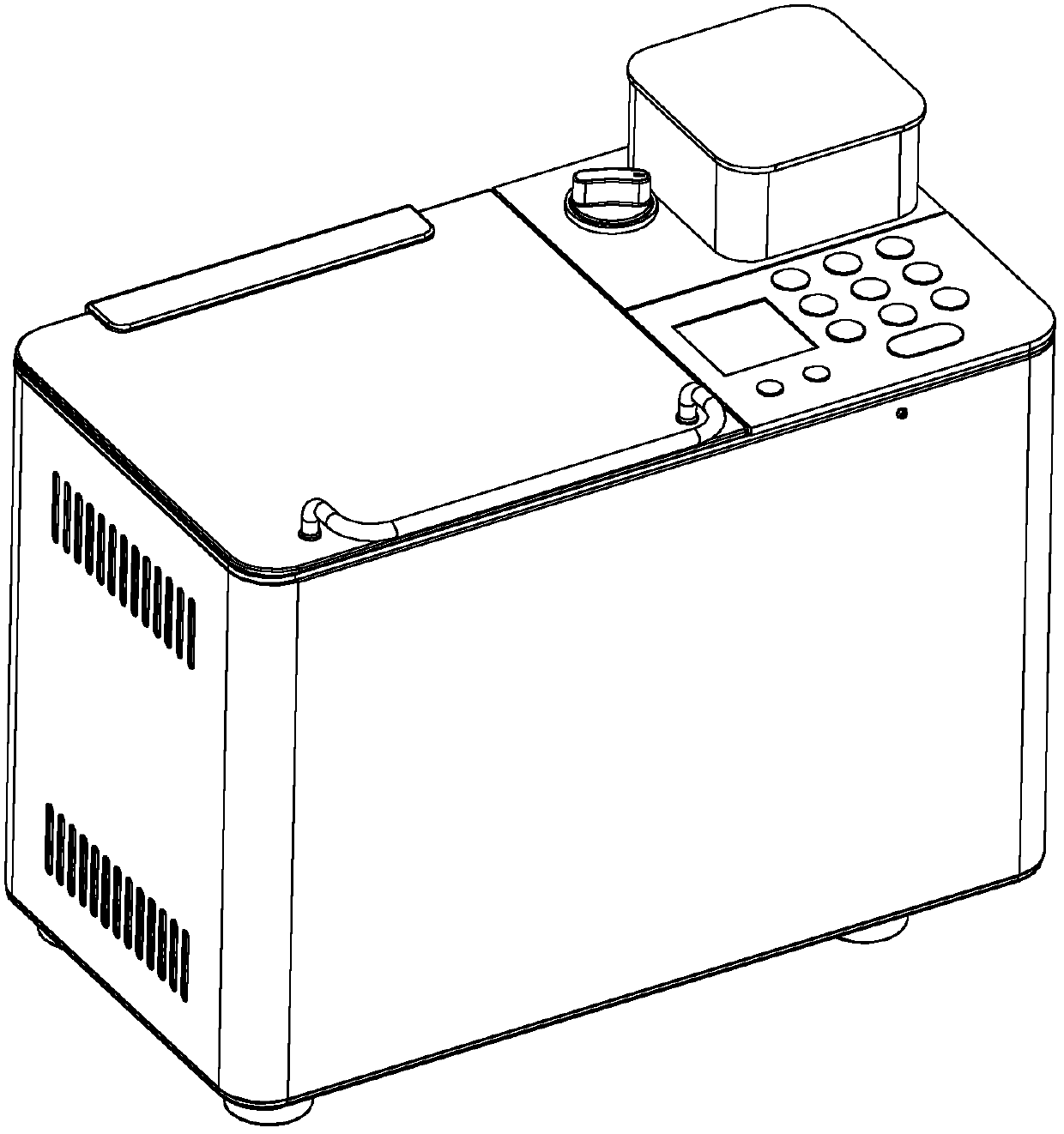

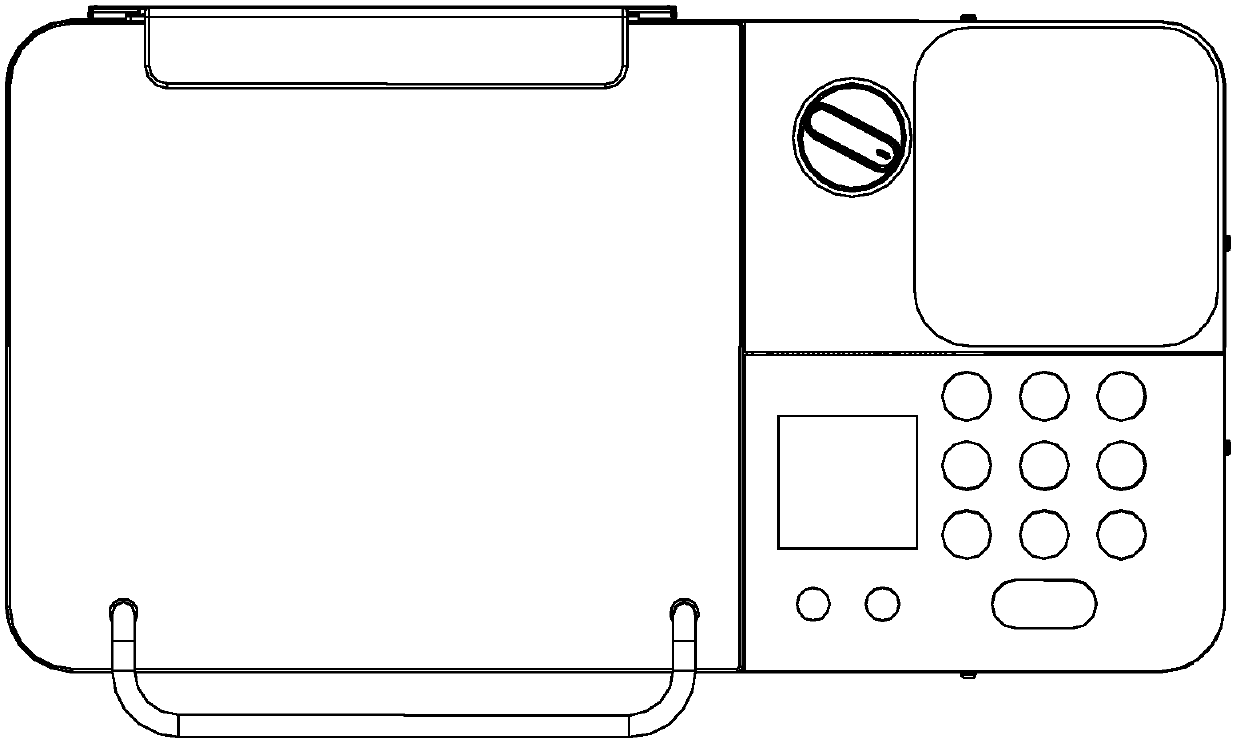

Full-automatic bread maker and bread making method

A bread machine, fully automatic technology, applied in the field of kitchen appliances, can solve the problems of user safety hazards, inconvenient operation of changing buckets, single function, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

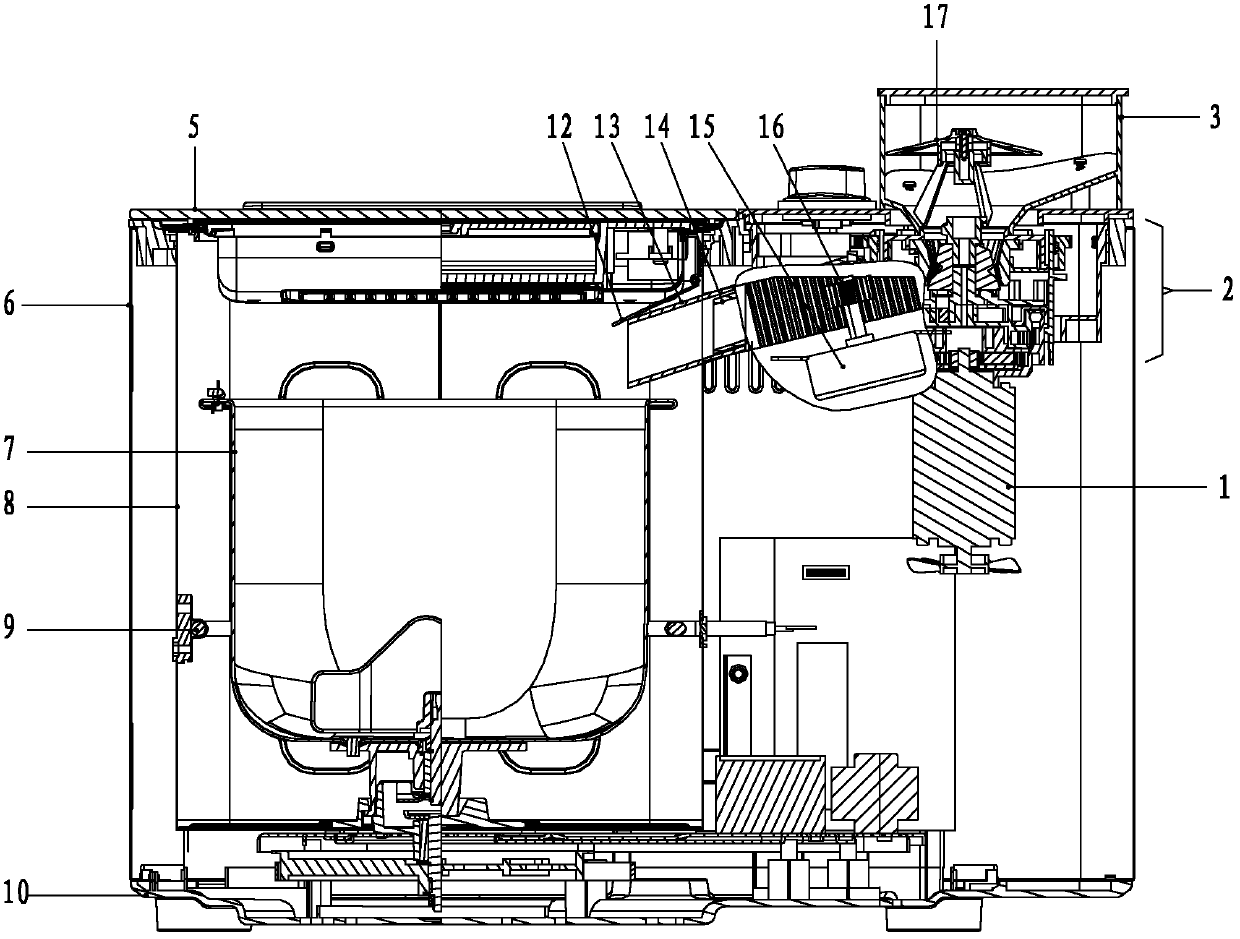

[0092] In the present embodiment, the whole rice flour bread making process principle is:

[0093] 1. Whole rice flour bread schedule:

[0094]

[0095]

[0096] Whole Rice Flour Bread Recipe:

[0097]

[0098]How to make rice flour bread:

[0099] Put the rice in the grinding wheel to grind the rice. After the rice is ground, it will automatically fall into the bucket of the bread machine. Stir the rice flour and bread making materials intermittently and slowly through the stirring rod to mix the rice flour and water together, and then stir quickly. Bread ingredients to form bread blanks;

[0100] Ferment the bread base, then put acid, fully and uniformly ferment again after the acid release, and finally bake the fermented bread base.

[0101] Due to the poor gas holding property of the dough formed by flour and water, after the bread raw materials are fully stirred into a blank, the bread blank is fermented, and then the acid is released, and then fermented again...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap