Base for circuit board hole plugging with resin

A technology of resin plugging holes and circuit boards, which is applied to the formation of electrical connections of printed components, etc., can solve the problems of wasting time and manpower, wasting manpower, and wasting production costs, so as to save manpower and material resources, reduce costs, and speed up the work process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

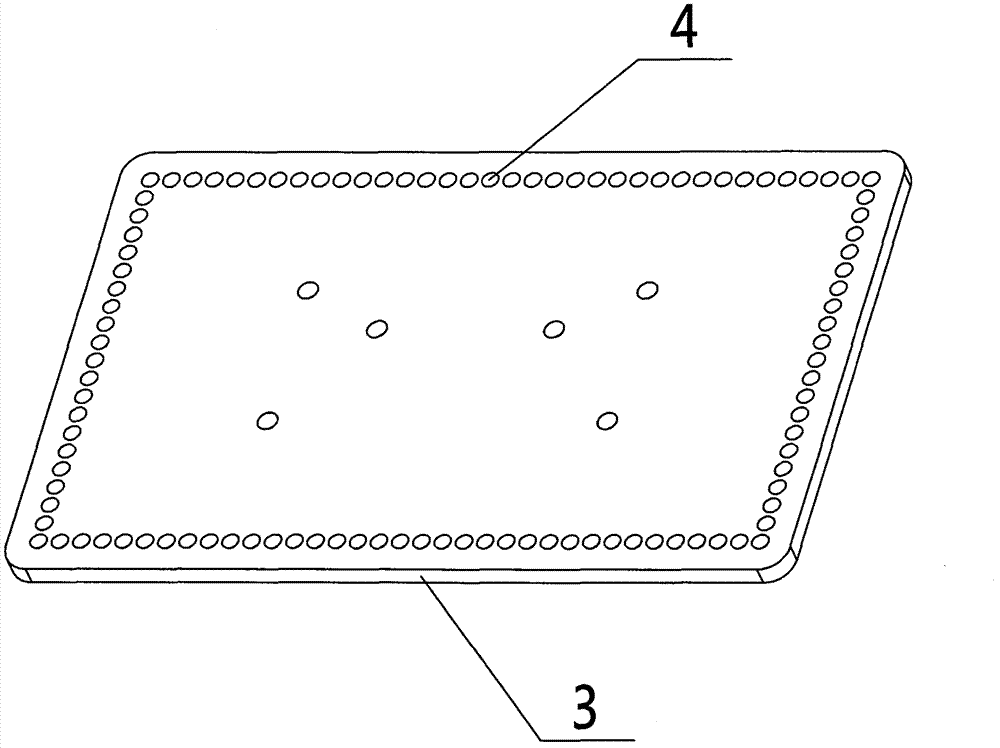

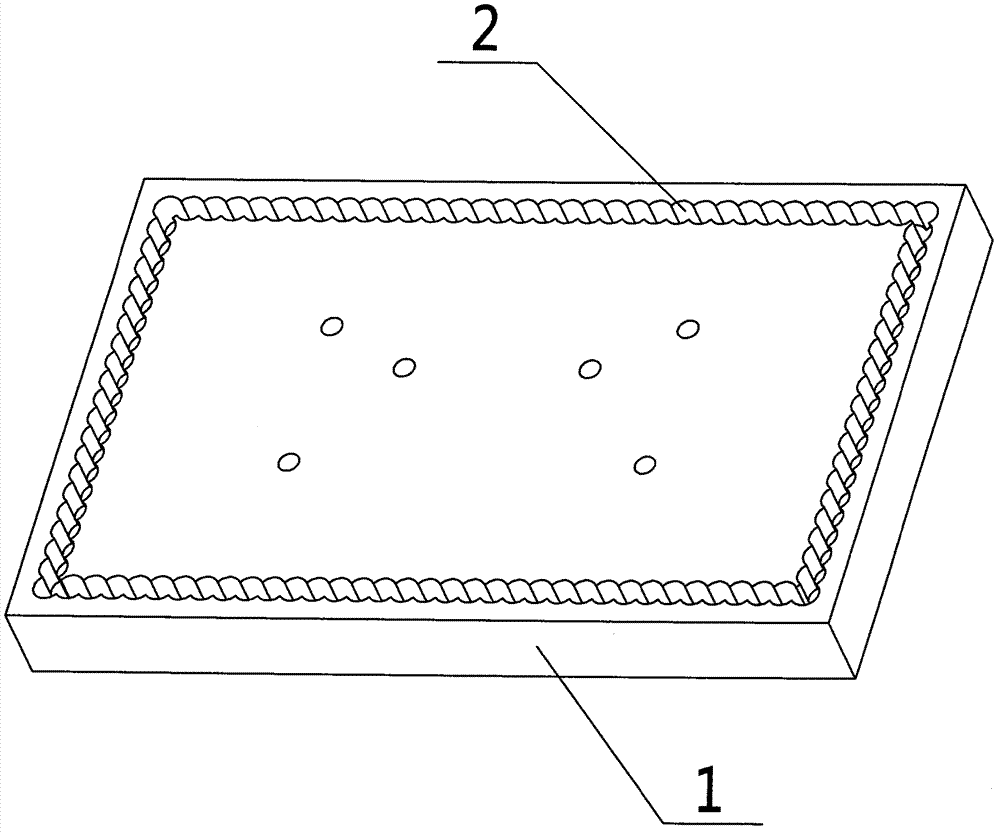

[0013] as attached figure 1 , 2 As shown, the base of a circuit board resin plug hole according to the present invention includes a base body 1; the thickness of the base body 1 is twice the thickness of a common base; the upper surface of the base body 1 is surrounded by blind holes The hole 2; the blind hole 2 corresponds to the hole 4 on the circuit board 1; the depth of the blind hole 2 is 0.5 times the thickness of the base body 1.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The base of the resin plug hole of the circuit board according to the proposal of the present invention only needs to make a base before plugging the hole, and the plugging operation of the dense holes on the entire circuit board can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com