Fixing structure of radiating element

A technology of fixed structure and heat dissipation components, applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of reduced heat transfer efficiency, loss of air tightness, easy generation of thermal resistance, etc., to avoid thermal resistance. phenomenon, long service life, increase the effect of tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

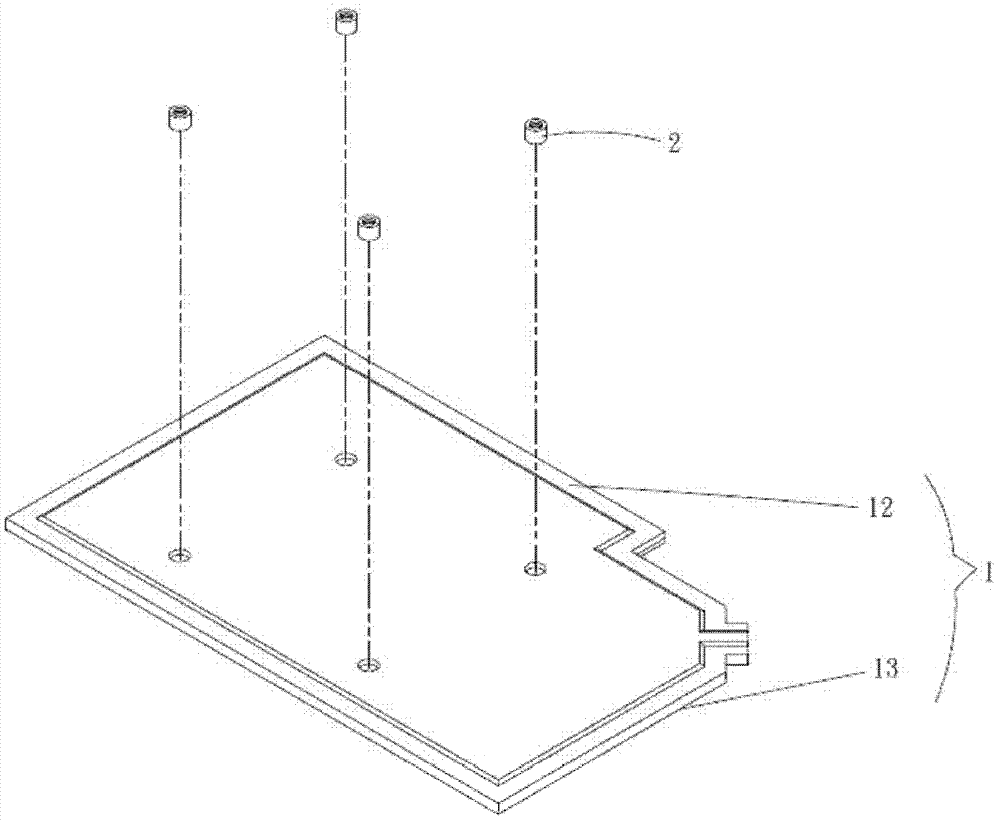

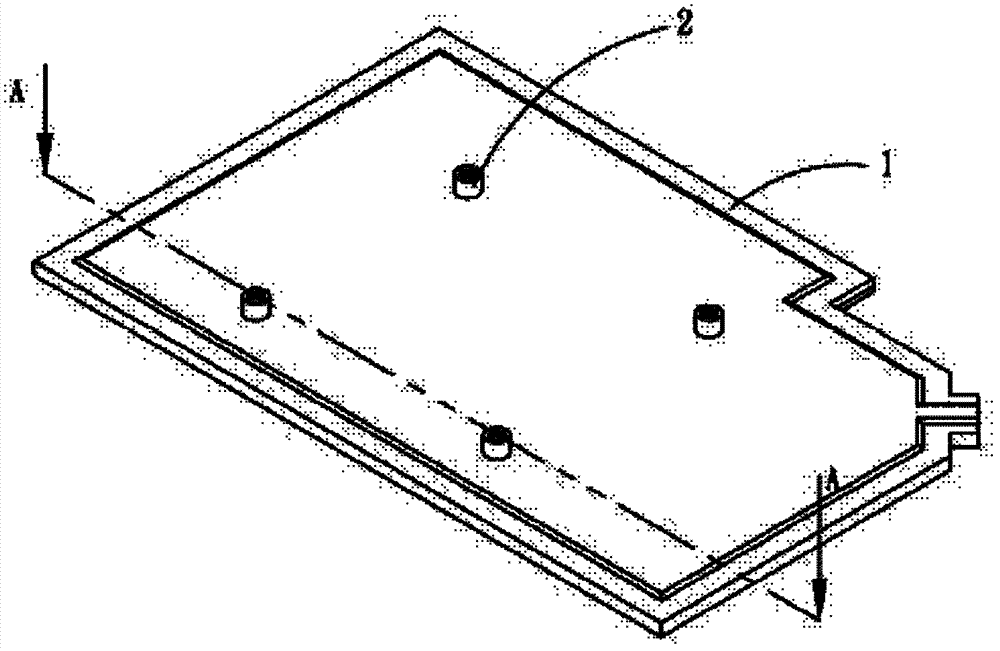

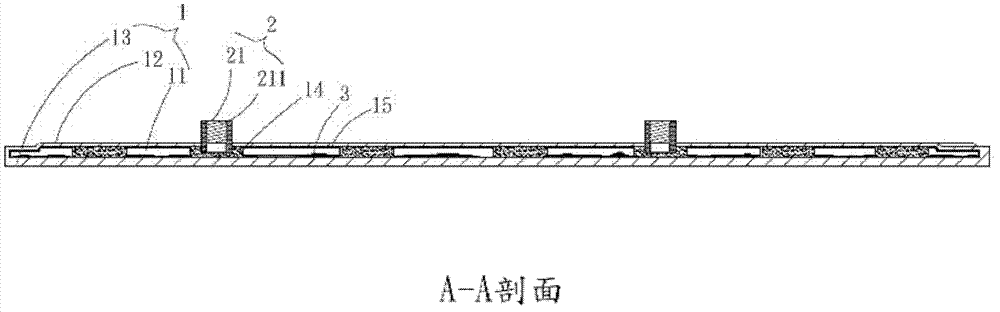

[0058] see figure 1 , figure 2 , image 3 , is the first embodiment of the fixed structure of the heat dissipation element of the present invention, the three-dimensional exploded and assembled view and the A-A sectional view, as shown in the figure, the fixed structure of the heat dissipation element of the present invention includes: a body 1, a plurality of fixed elements 2 ;

[0059] The body 1 has a chamber 11 and a first side 12 and a second side 13, the chamber 11 has a plurality of supports 14, working fluid 3 and at least one capillary structure layer 15, the supports 14 are Connecting the aforementioned first and second sides 12, 13, the capillary structure layer 15 is completely attached to the aforementioned chamber 11

[0060] The fixing element 2 has a hole 21 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com