A sealed water-cooled plate structure applied to lithium battery modules

A water-cooled plate and lithium battery technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as water leakage and axial sealing ring loose fit, and achieve the effects of avoiding water leakage, ensuring safety, and improving waterproof leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

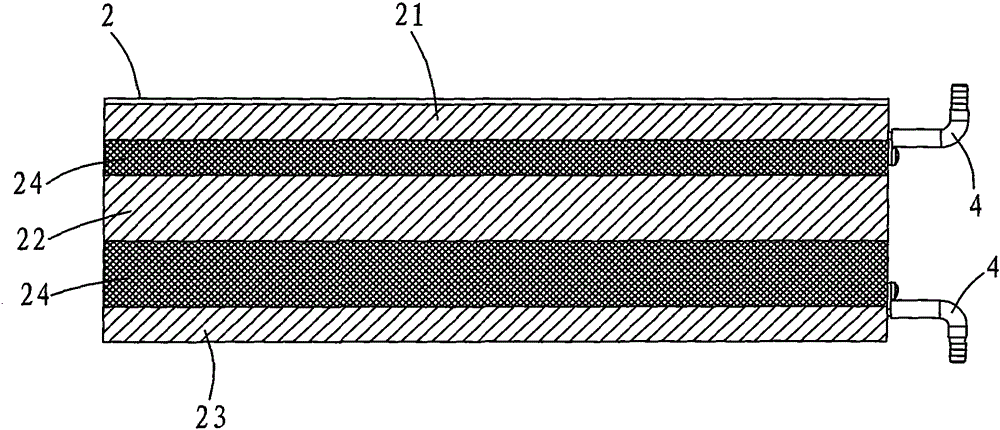

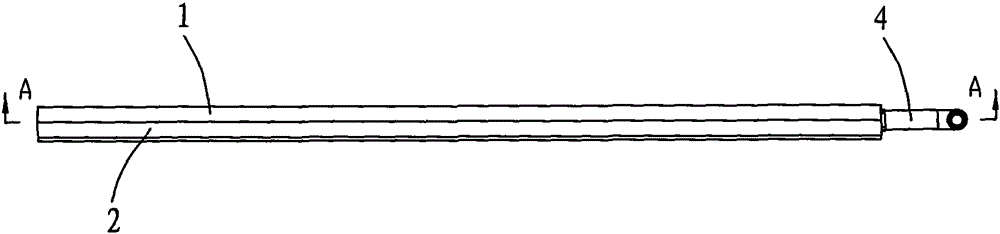

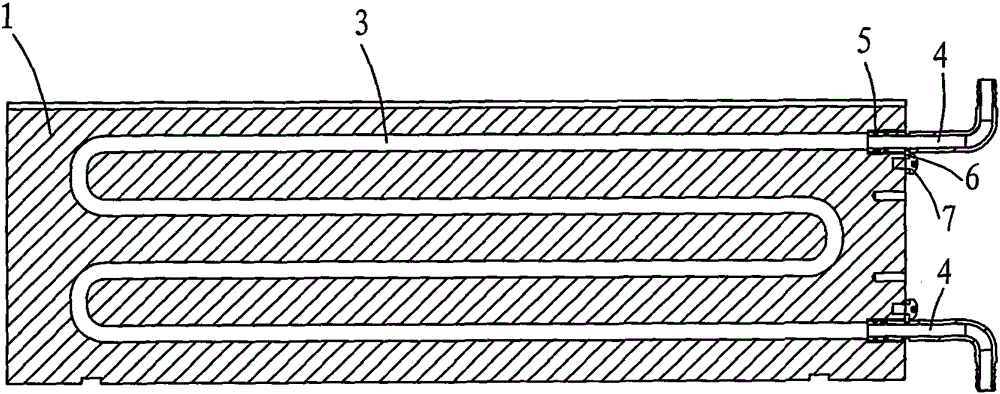

[0020] see figure 1 , figure 2 with image 3 According to the embodiment of the present invention, a sealed water-cooled plate structure applied to a lithium battery module includes an aluminum plate 1 and an aluminum cover plate 2 welded together, the aluminum plate 1 is die-cast with a water-cooled channel 3, the inlet end of the water-cooled channel 3 and The outlet ends are respectively plugged with rotatable water-cooled joints 4, and the peripheral wall of the plug-in part of the rotatable water-cooled joints 4 is embedded with two radial sealing rings 5 distributed in the axial direction. The hole wall of the channel 3 is sealed and fitted, and an axial limiting pressing piece 6 is embedded on the outer side of the plug-in part of the rotatable water-cooled joint 4, and the axial limiting pressing piece 6 is locked on the aluminum plate 1 by a screw 7 (or It is on the aluminum cover plate 2) to prevent the plug-in part of the rotatable water-cooling joint 4 from ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com