Motor gear for valve electric actuator

A motor gear, valve electric technology, applied in the direction of electric components, engine components, valve operation/release devices, etc., can solve the problems of high cost, poor wear resistance, low strength of plastic gears, etc., to prolong the service life and simple structure Reliable, increased tight fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

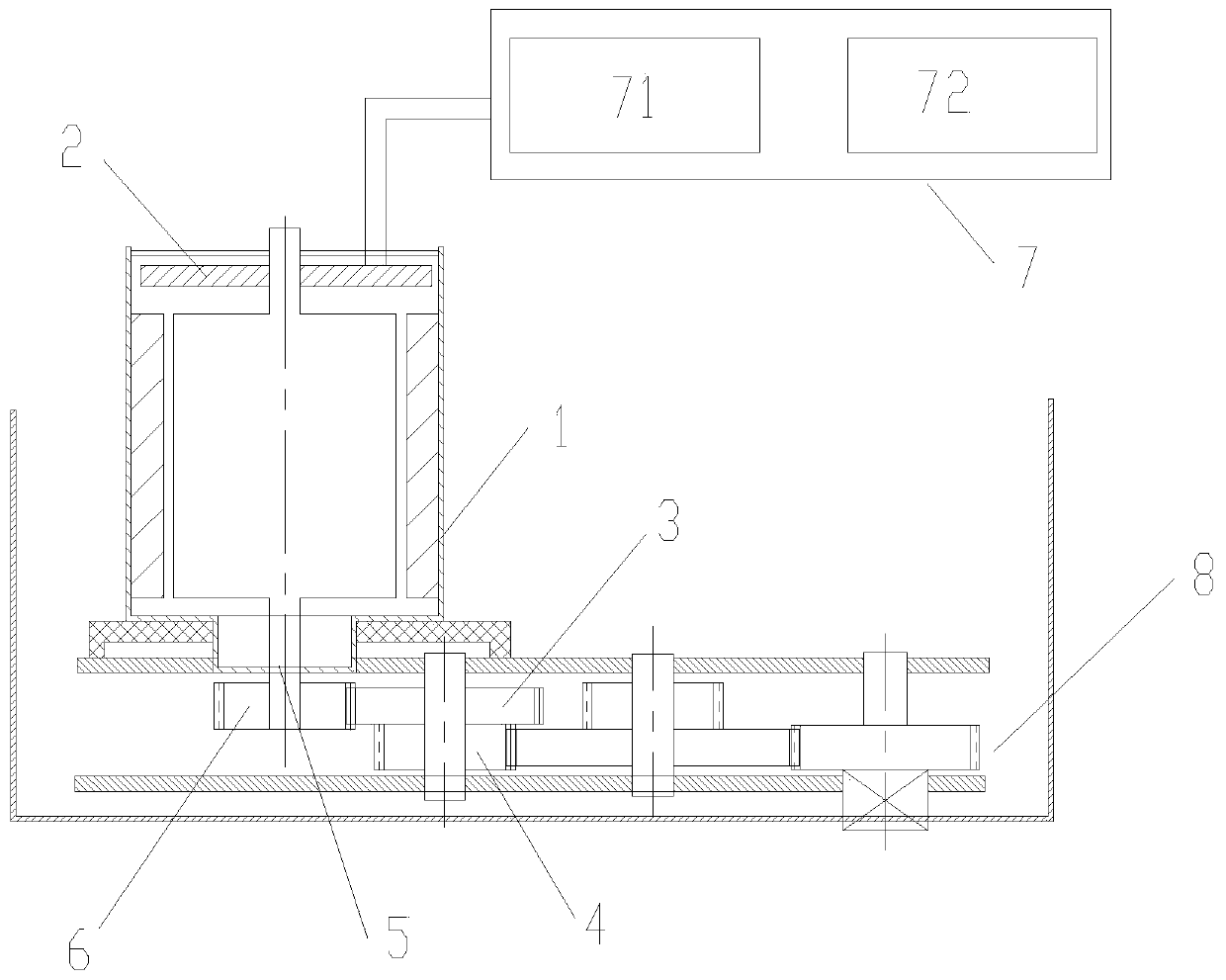

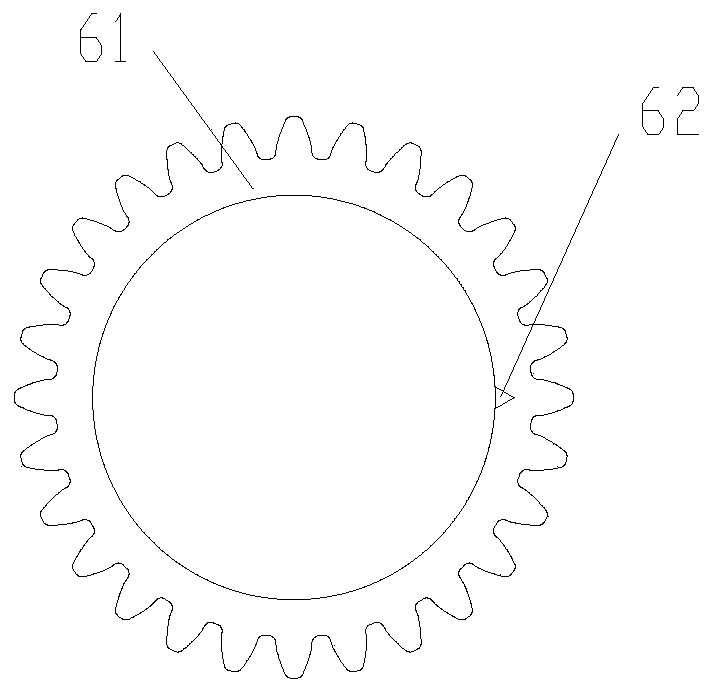

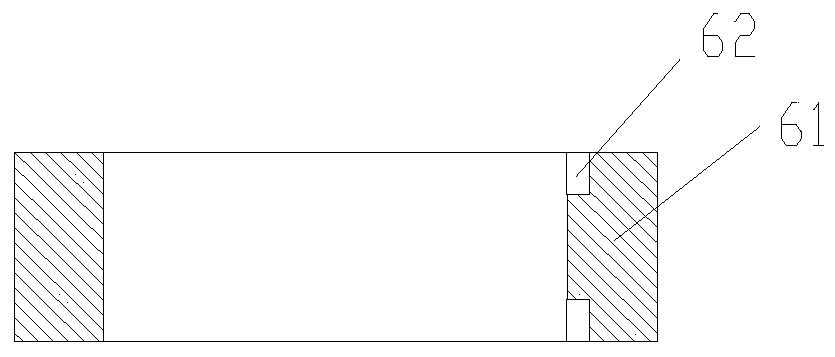

[0047] Such as Figure 2 to Figure 11 As shown, the embodiment of the present invention discloses an insulated motor gear for an actuator, including an outer metal gear 61, a metal sleeve 65 and an insulating spacer 63, and the metal sleeve 65 is concentrically arranged in the outer metal gear 61, The outer metal gear 61 and the metal sleeve 65 are connected through an insulating spacer 63 , and the outer metal gear 61 and the metal sleeve 65 are fixedly connected to the insulating spacer 63 respectively. The material of the insulating spacer 63 is a non-conductive non-metallic material, which can be obtained by injection molding or machining. For example, the insulating spacer 63 can be an injection molded part, and the fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com