Flock printing screen printer and rail wheel automatic limit device thereof

A technology of automatic limit and track wheels, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems affecting the quality of flocking printing, offset, etc., and achieve the effect of precise limit and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

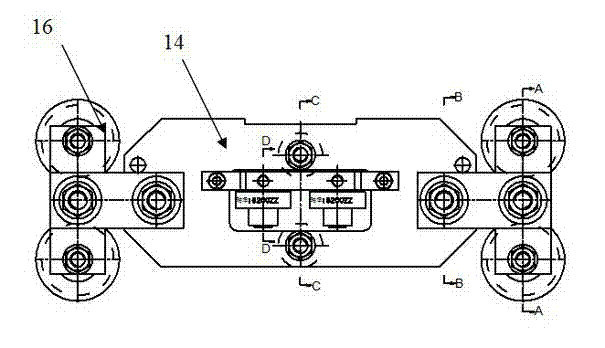

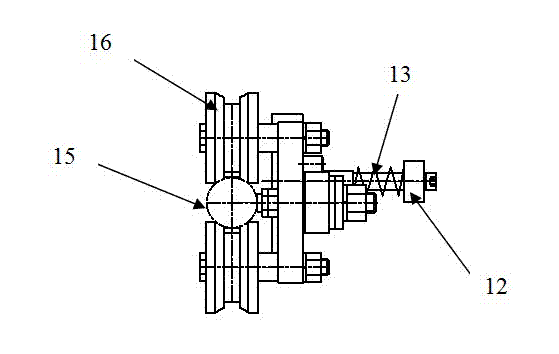

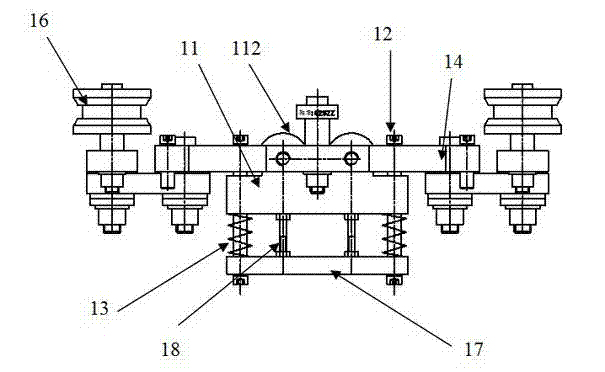

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, the present invention flocking printing screen printing machine track wheel automatic limiter, including a pressing member 11, at least one slide bar 12 and springs 13 corresponding to the number of slide bars 12, the head end of the slide bar 12 is fixed on the track wheel On the mounting bracket 14, the pressing member 11 is provided with through holes 111 corresponding to the number of the slide bars 12, the pressing member 11 is sleeved with the slide bar 12 through the through holes 111, the spring 13 is sleeved with the slide bar 12, and one end of the pressing member is pressed against the pressing member 12. The other end of the pressing part 11 is against the slide bar 12 , the pressing part 11 is against the track 15 , and the pressing part 11 transmits the tension of the spring 13 to continuously exert pressure on the track 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com