Tea leaf aroma extraction method and application

An extraction method and technology of tea leaves, which are applied in the field of food and beverages, can solve the problems of undiscovered patent publications, etc., and achieve the effects of shortening the pretreatment time, reducing the number of uses, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for extracting tea aroma, the steps are as follows:

[0053] 1. Tea aroma is extracted by steam distillation in microwave water

[0054] Put 50.0g of tea leaves such as cinnamon oolong tea or its related product samples and deionized water into the sample bottle according to the mass ratio of sample: deionized water of 1:5-10, and heat the sample bottle with microwave as the heat source under stirring conditions. Microwave heating, the microwave power is 200W, and the temperature of the control system is at 90°C. After the distillate is condensed by the condenser, it is continuously heated until there is no distillate. The whole extraction process lasted for 60 minutes, and then 10-15 ml of the tea aroma extract was taken out from the volatile oil collector, collected and protected from light for later use.

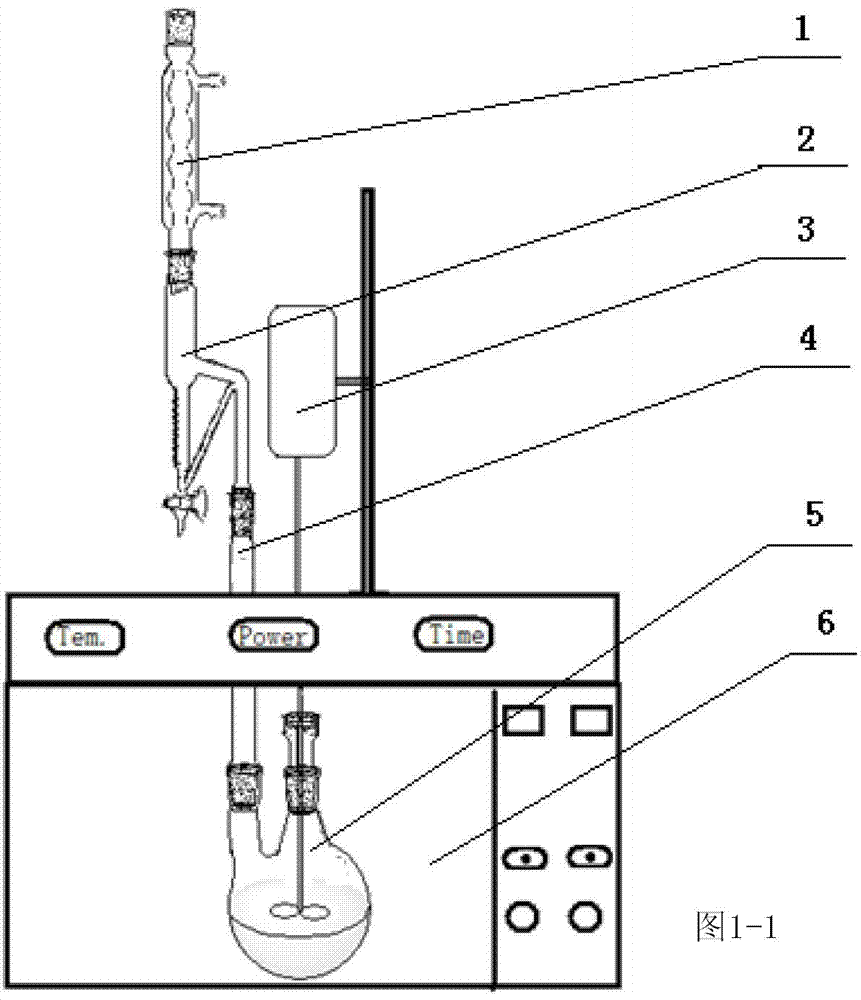

[0055] The schematic diagram of the device for extracting tea aroma by steam distillation in microwave water is shown in Picture 1-1 . Wherein, the i...

Embodiment 2

[0069] A method for extracting tea aroma, the steps are as follows:

[0070] 1. Microwave water steam distillation extracts tea aroma

[0071] Put 50.0 g of cinnamon oolong tea or related tea products into a steam generating bottle filled with deionized water (1 / 2 bottle volume) and some glass beads (to prevent bumping), and use microwave as a heat source to heat the steam generating bottle Carry out microwave heating, microwave power is 400W, control system temperature at 90 ℃. The distillate is condensed by the condenser tube, and the heating is continued until there is no distillate. The whole experiment process lasted 45 min. Then take out about 10-15 milliliters of the tea aroma extract from the volatile oil collector, collect and keep away from light for later use.

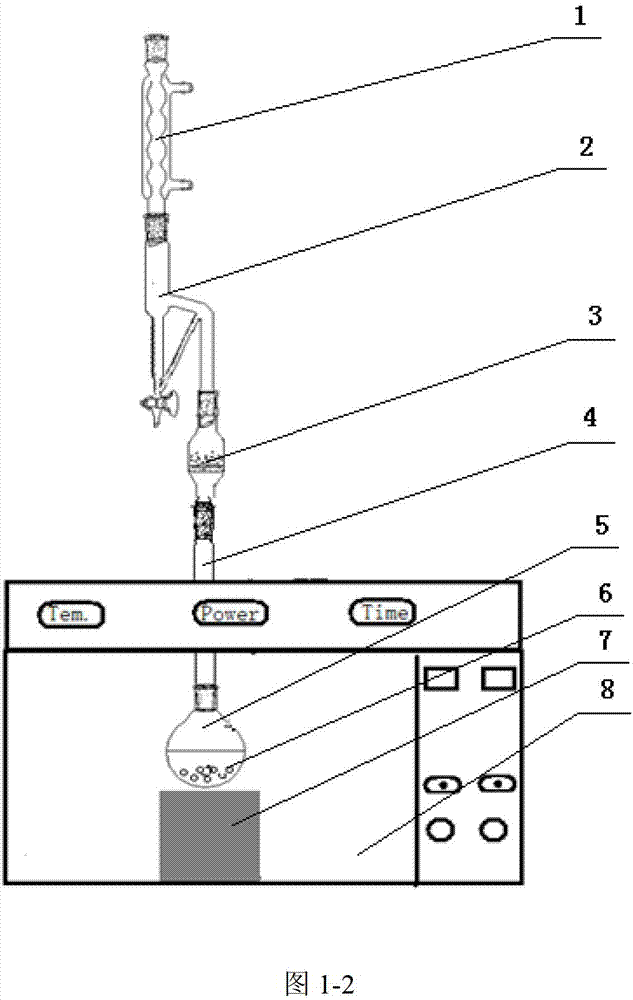

[0072] The schematic diagram of the device for extracting tea aroma by steam distillation over microwave water is shown in Figure 1-2 . Wherein, glass beads 6 for anti-bumping are housed in the water v...

Embodiment 3

[0085] A method for extracting tea aroma, the steps are as follows:

[0086] 1. Solvent-free microwave steam distillation to extract tea aroma

[0087] Put 50.0 g cinnamon oolong tea sample into the sample bottle, and spray the tea leaves with an appropriate amount of deionized water to make the surface wet (humidity is controlled between 10%-30%). The device is the same as in Example 1. Under stirring conditions, microwave The extraction bottle was heated by microwave as a heat source, the microwave power was 200W, and the temperature of the control system was 90°C. The distillate is condensed by the condenser tube, and the heating is continued until there is no distillate. The whole experiment process took 15 minutes. Collect the volatile oil to obtain tea aroma extract (10-15 ml), keep away from light for later use.

[0088] 2. Purification of tea aroma

[0089] ①Concentrate the tea aroma extract under reduced pressure at 45°C and 40-60mbar to obtain a concentrate, pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com