Soy sauce prepared from hypsizygus marmoreus, and preparation method of soy sauce

A technology of crab-flavored mushrooms and soy sauce, which is applied in the fields of application, the function of food ingredients, and food ingredients as odor improvers. Highlight, improve color and flavor, and reduce bad flavor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Crab taste mushroom pretreatment

[0029] 1) Selection of crab-flavored mushrooms:

[0030] Choose crab-flavored mushrooms that are disease-free, insect-free, rot-free, odor-free, pesticide residues and harmful metals do not exceed the standard, and have a complete structure and crisp texture. Clean them after removing impurities.

[0031] 2) Sliced crab-flavored mushrooms

[0032] Cut large crab-flavored mushrooms into 4 pieces, so that the cross-sectional area is less than 1mm 2 ;

[0033] 3) Pre-baked crab-flavored mushrooms

[0034] Bake at 110°C for 60 minutes, the color of crab-flavored mushrooms will turn yellow and have aroma.

[0035] 4) Baked Crab Mushroom

[0036] Bake at 150°C for 15 minutes, so that the color of the crab-flavored mushrooms turns yellowish-brown, it has a roasted crab-flavored mushroom aroma, and tastes without bitterness.

Embodiment 2

[0037] Embodiment 2: Screening of protease for enzymatic hydrolysis of crab-flavored mushrooms

[0038] Crush the roasted crab-flavored mushrooms, add deionized water, the ratio of solid to liquid is 1:6, the pH is natural, and use different types of protease (500U / g) and flavor protease (2500U / g) for 4 hours at 45°C. The enzymatic hydrolyzate of roasted crab-flavored mushrooms was prepared.

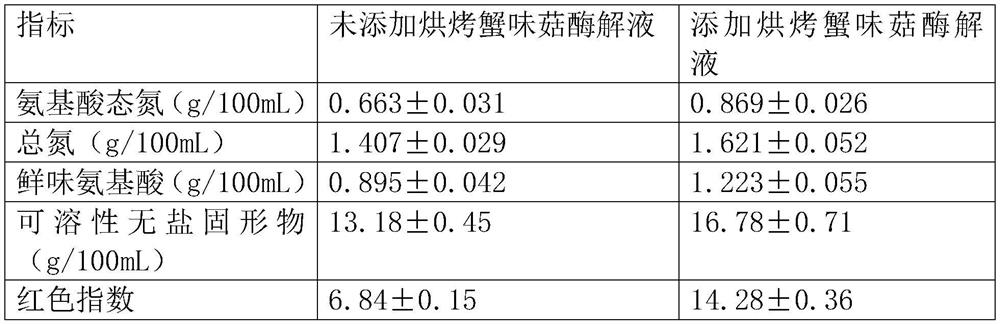

[0039] Table 1: Effect of different proteases and flavor proteases on the quality of the enzymatic hydrolyzate of crab-flavored mushrooms

[0040] Protease type Umami amino acid (g / 100mL) flavor protease 0.535±0.019 Flavor protease + papain 0.703±0.027 Flavor Protease + Alkaline Protease 0.592±0.015 Flavor protease + neutral protease 0.712±0.025 Flavor Protease + Bromelain 0.697±0.022 Flavor Protease + Acid Protease 0.689±0.021

[0041] It can be seen from Table 1 that the umami amino acid content in the roasted crab-flavored mushroom l...

Embodiment 3

[0043] 1) Selection of crab-flavored mushrooms:

[0044] Choose mature crab-flavored mushrooms that are disease-free, insect-free, rot-free, odor-free, and pesticide residues and harmful metals do not exceed the standard. Clean them after removing impurities.

[0045] 2) Pretreatment of crab-flavored mushrooms

[0046] Cut large crab-flavored mushrooms into 4 pieces, the cross-sectional area is less than 1mm 2 , baked at 110°C for 60 minutes, and baked at 130°C for 45 minutes, so that the color of the crab-flavored mushroom slices turns yellowish brown, with the aroma of roasted crab-flavored mushrooms, and no bitterness in the mouth.

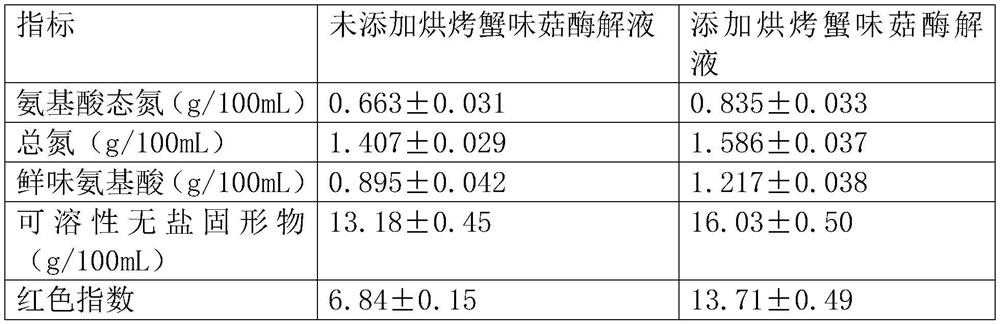

[0047] 3) Protease hydrolysis

[0048] The crab-flavored mushrooms treated in step 1) were crushed, added with deionized water, the ratio of solid to liquid was 1:6, the pH was natural, and enzymatically hydrolyzed with flavor protease and neutral protease (5:1) for 4 hours at 45°C to obtain baked Grilled crab-flavored mushroom enzyme hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com