Low-volatilization hotpot condiment and preparing method thereof

A hot pot base material and low volatilization technology, which is applied in the field of food processing, can solve the problems of large power consumption, high cost, and increased business operation cost, and achieve the effects of simple treatment method, low cost and increased operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

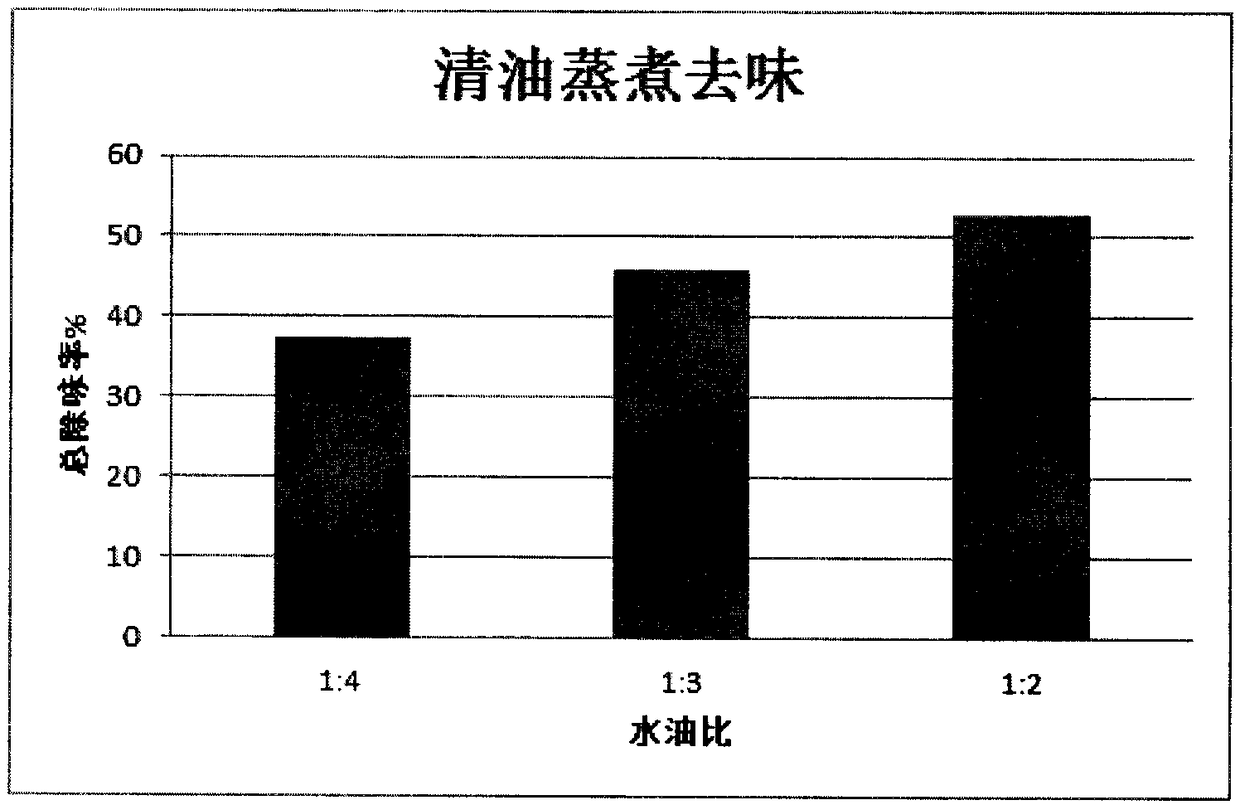

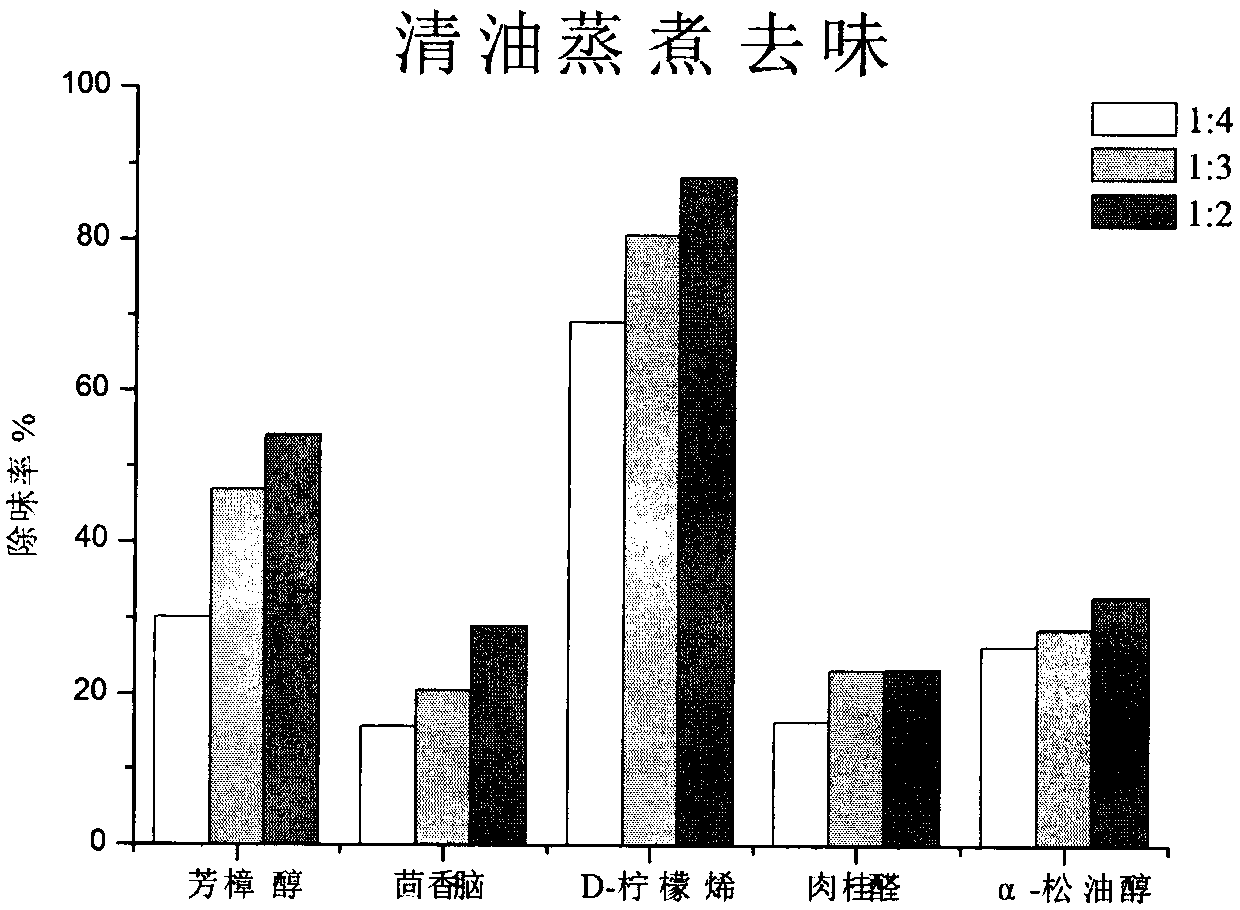

[0028] The effect of different water-oil ratios on the removal rate of flavor substances in hot pot bottom material was investigated.

[0029] Heat the ordinary hot pot base material until the temperature reaches 90°C, then add clear water to the ordinary hot pot base material according to the mass ratio of water: ordinary hot pot base material is 1:2, 1:3, 1:4, continue heating, when the temperature When the temperature reaches 120°C, the heating is stopped, and the low-volatile hot pot bottom material is obtained. Through GC-MS analysis, the analysis and comparison of the low-volatile hot pot base materials treated with different proportions of water were carried out. Such as figure 1 As shown, under the same conditions, the removal rate of the total flavor substances in the clear oil bottom material increases with the increase of water, and can reach more than 50%. Such as figure 2 As shown, the removal rate of various substances also increased with the increase of wate...

Embodiment 2

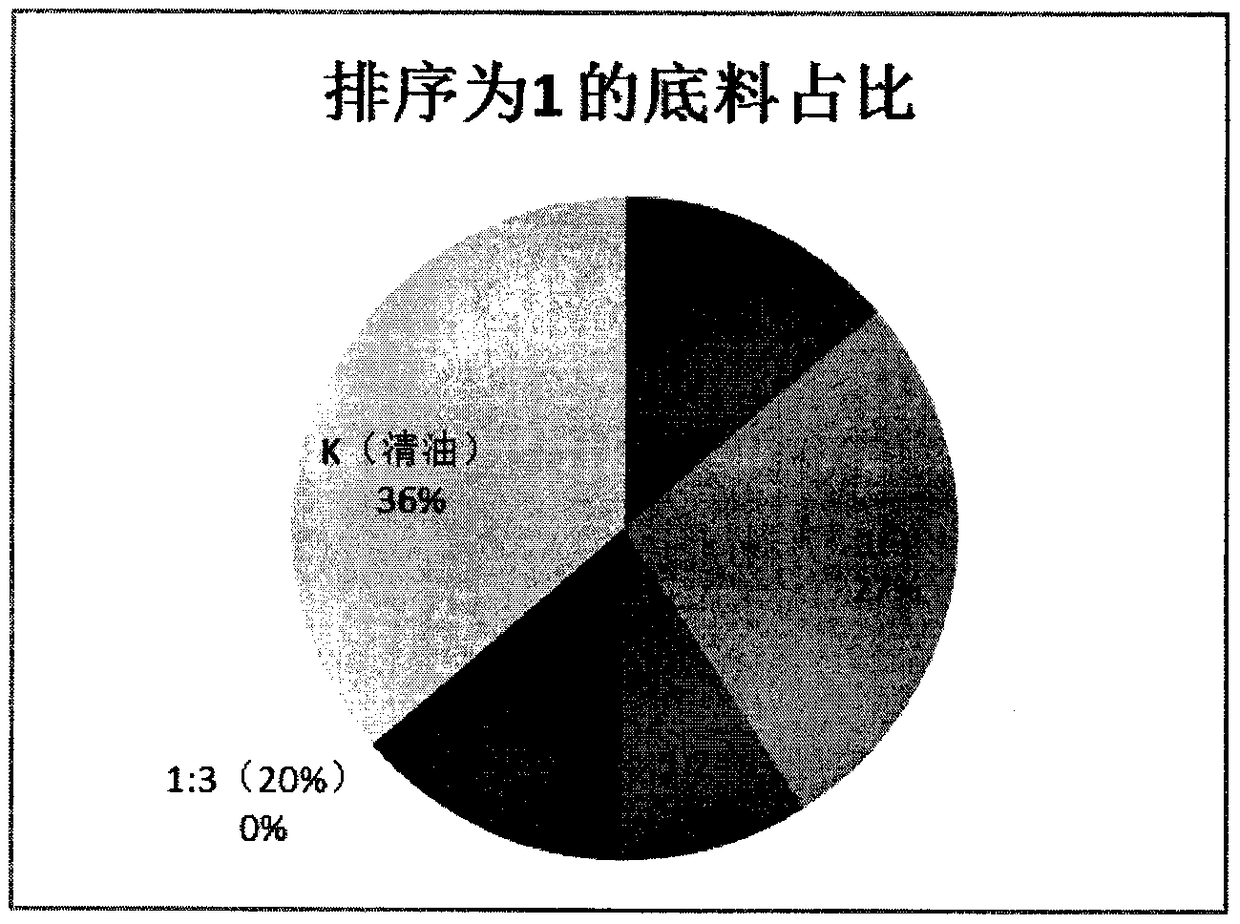

[0031] To investigate the effects of different water-oil ratios or edible alcohol aqueous solution: oil ratios on the sensory quality of hot pot bottom ingredients.

[0032] Prepare the low-volatile chafing dish bottom material according to the method substantially the same as Example 1, the difference is that water: the mass ratio of common chafing dish bottom material (water-oil ratio) is respectively 1: 2, 1: 3, 1: 4;

[0033] Or prepare the low-volatile chafing dish bottom material according to the method substantially the same as Example 1, the difference is that water is replaced by an aqueous edible alcohol solution, and the mass percentages of the aqueous edible alcohol solution are 10%, 20%, respectively, and the aqueous edible alcohol solution : The mass ratio of common chafing dish bottom material is 1: 3.

[0034] The sensory evaluation results are as follows:

[0035]

[0036] Note: (1) Treatment conditions: Add water or edible alcohol aqueous solution when th...

Embodiment 3

[0044] The effect of different proportions of water vapor on the removal rate of flavor substances in hot pot bottom material was investigated.

[0045] Prepare the low-volatile hot pot bottom material in the same manner as in Example 1, the difference being that the mass ratios of water vapor: common hot pot bottom material (the ratio of water vapor to oil) are 1:2, 1:3, and 1, respectively. : 4. Through GC-MS analysis, the analysis and comparison of the hot pot bottom material with different proportions of water vapor, and then processed by cooking, such as Figure 7 As shown, under the same conditions, the total removal rate of flavor substances in the clear oil bottom material increases with the increase of the quality of water vapor, and can reach more than 50%. Such as Figure 8 As shown, the removal rate of various substances also increases with the increase of water vapor mass. The removal rate of linalool increased from 30.3% to 60.5%, the removal rate of anethole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com