Vehicle dual clutch transmission

A dual clutch and clutch technology, applied in gear transmissions, components with teeth, belts/chains/gears, etc., can solve the problems of transmission wear, sliding surface cracking, shaking, etc., to maintain drivability, reduce effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

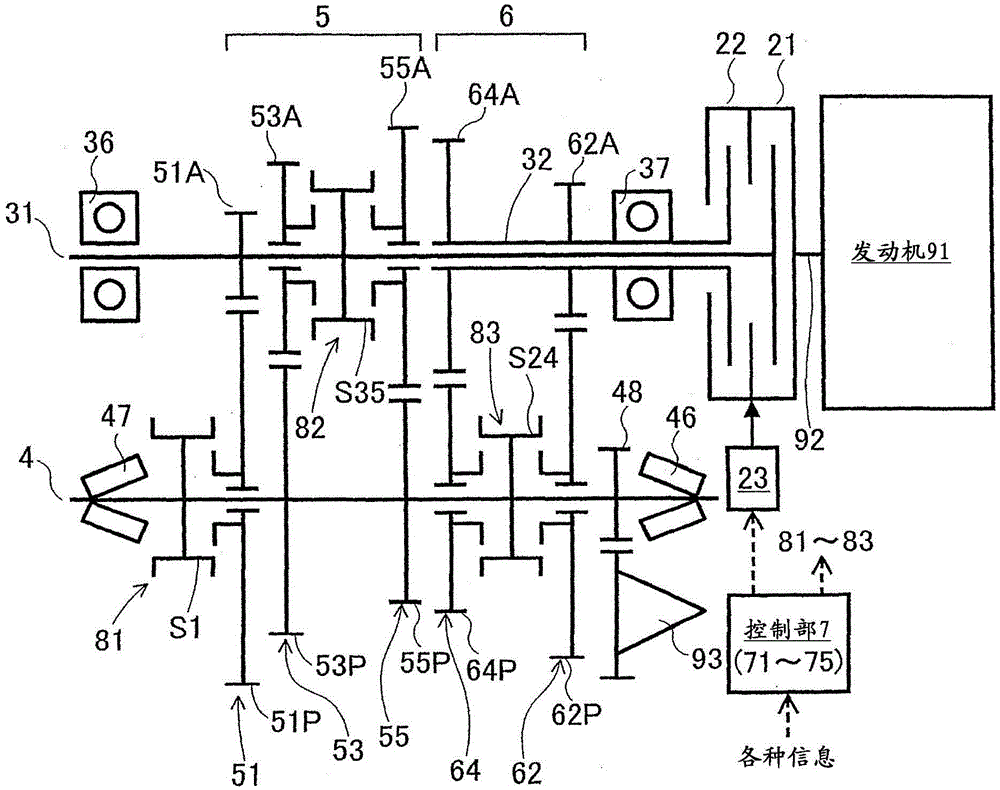

[0033] refer to Figure 1~Figure 9 Embodiments for carrying out the present invention will be described. figure 1 It is a configuration diagram showing a vehicle dual-clutch transmission 1 according to an embodiment of the present invention. The vehicle dual-clutch transmission 1 is a device that selects five forward gears and one reverse gear, and can transmit the output torque of the engine 91 to the differential 93 in an engaged and disengaged manner. The vehicle dual-clutch transmission 1 is composed of a first clutch 21 and a second clutch 22, a first input shaft 31, a second input shaft 32, an output shaft 4, a first speed change mechanism 5, a second speed change mechanism 6, a control unit 7, etc. constitute.

[0034] The first clutch 21 and the second clutch 22 are parts that independently switch between an engaged state that is rotationally coupled to an output shaft 92 of an engine 91 serving as a power source, and a disengaged state that is disconnected from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com