Multi-station compound hollow insulator flange cementing machine

An insulator and multi-station technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of incomplete compression of sealing rings, unstable quality, and high energy consumption, so as to prevent product voltage deviation, product stability, and The effect of low heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

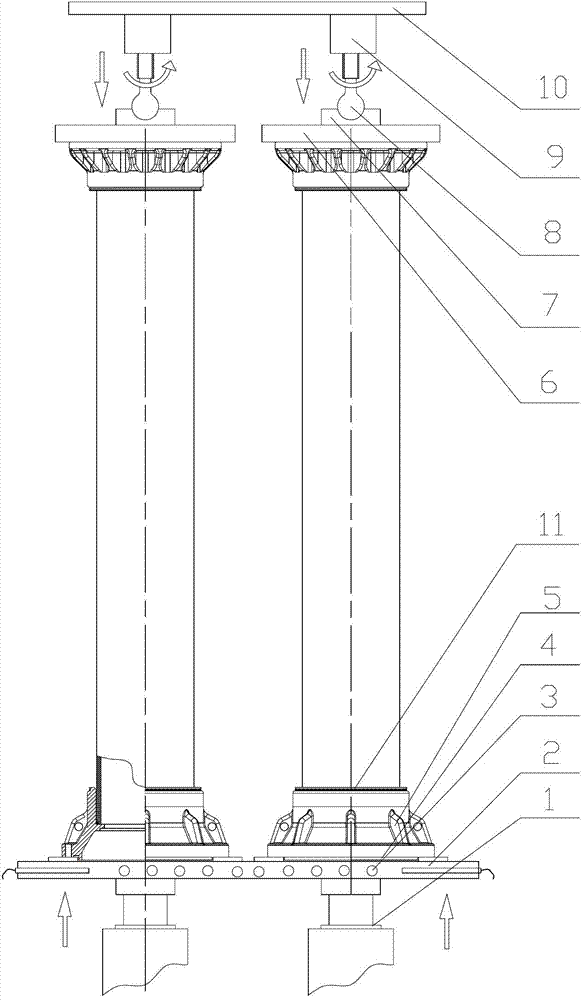

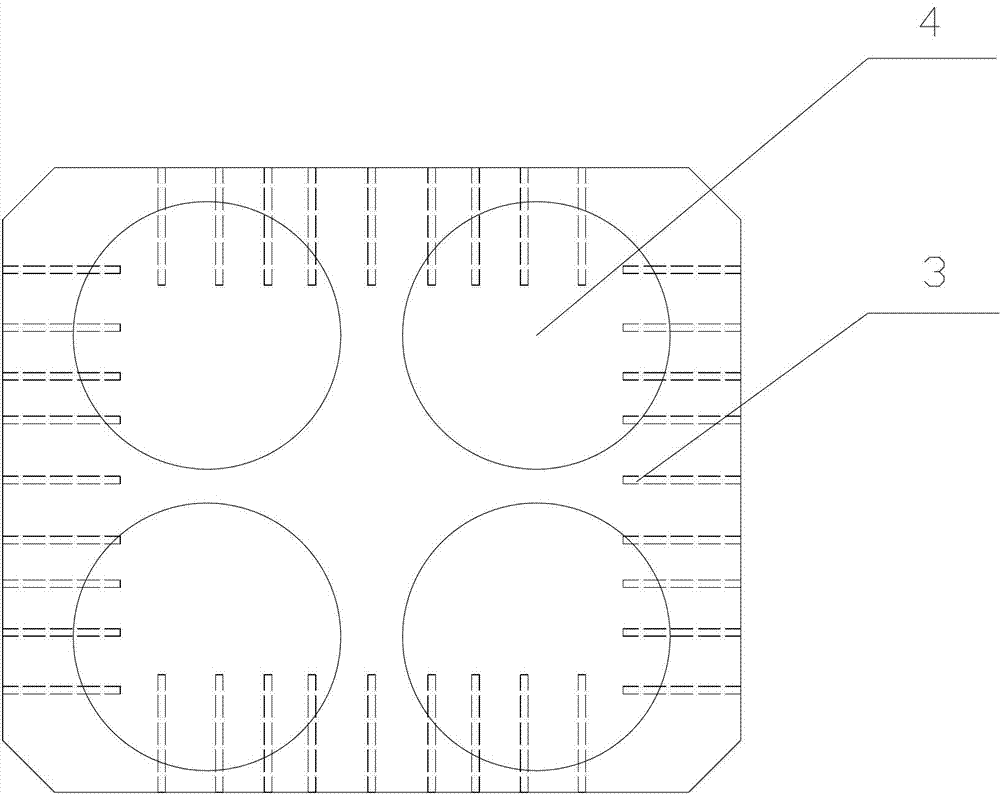

[0017] like figure 1 , 2 As shown, the multi-station composite hollow insulator flange gluer includes a base plate 2 and a top plate 10, the base plate 2 is provided with a heating device 3, and the base plate 2 is provided with 4 hydraulic cylinders 1, and the base plate 2 corresponds to 4 hydraulic cylinders 1 There are 4 flange fixing devices 5 at the position; there are 4 adjusting and pressing devices corresponding to the 4 flange fixing devices 5 under the top plate 10; 4 hydraulic cylinders 1, 4 flange fixing devices 5 and 4 adjusting pressure The tightening device is composed of 4 groups of stations. Designed in this way, this glue-fitting machine can realize the glue-fitting of 4 sets of composite hollow insulator flanges, and can use the hydraulic cylinder 1 to pre-compress, and then use the heating device 3 to heat, and then use the adjusting and compressing device to adjust, and the sealing ring 11 Compressed in place.

[0018] The 4 adjusting and pressing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com