A manufacturing method of reverse conduction integrated gate commutated thyristor

A technology of gate commutation and manufacturing methods, which is applied in the direction of thyristor, semiconductor/solid-state device manufacturing, semiconductor devices, etc., and can solve the problem of low diffusion control precision, complicated process and unsuitable high voltage of reverse conduction integrated gate commutation thyristor. Devices and other issues, to increase the complexity of the process, improve the isolation effect, improve the effect of the punch-through voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

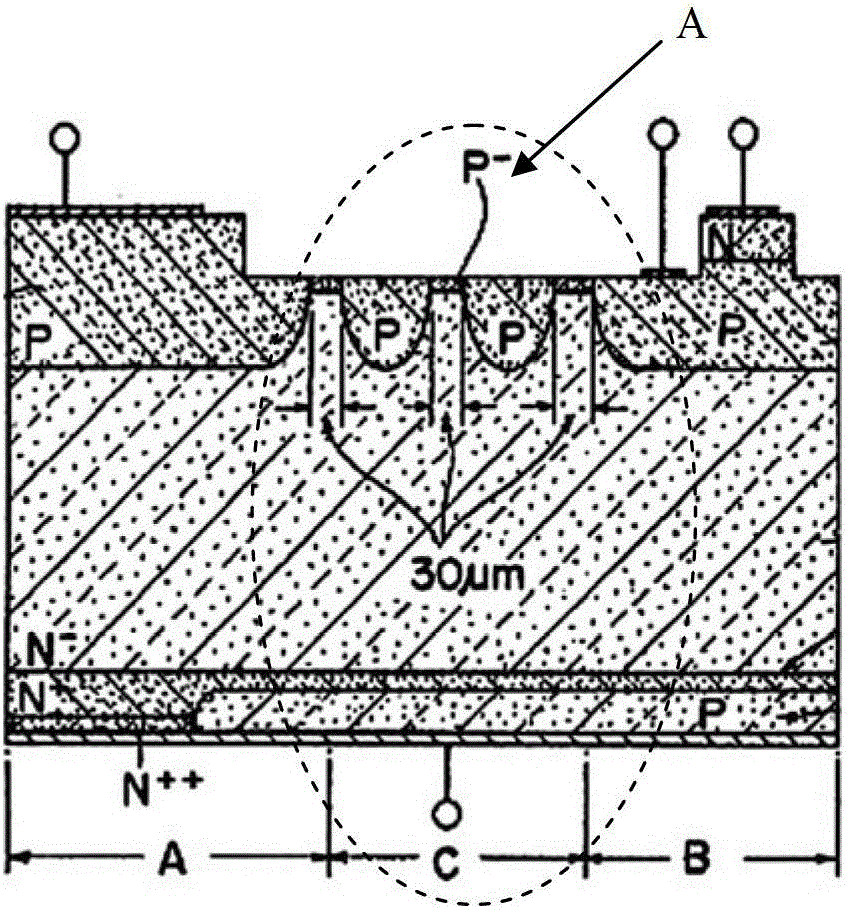

[0088] as attached Figure 12 to attach Figure 19 Shown is a specific implementation of a reverse conduction integrated gate commutated thyristor manufacturing method of the present invention, including the following steps:

[0089] S100: as attached Figure 12 As shown, a layer of N' impurity is lightly doped on one side of the original N-substrate 6, and the N' impurity is phosphorus;

[0090] S101: as attached Figure 13 As shown, make the P-type base region 5 of GCT and the P-type base region 10 of FRD;

[0091] S102: as attached Figure 14 As shown, the N′ impurity doping treatment is performed on the other side of the N-substrate 6 (the side where the GCT anode is located), and the dopant is phosphorus;

[0092] S103: as attached Figure 15 As shown, N+ pre-deposition treatment is performed on the GCT cathode and the FRD cathode, and the dopant is phosphorus;

[0093] S105: as attached Figure 17 As shown, N+ advance and passivation treatment are carried out on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com