A Motor Controller with Hierarchical Multi-Core Structure

A motor controller and motor control technology, which is applied in the direction of single motor speed/torque control, electronic commutator, generator/motor, etc. Complex and changeable situations, etc., to achieve the effect of strong upgrade ability, close connection and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by specific embodiment and in conjunction with accompanying drawing, the present invention is described in further detail:

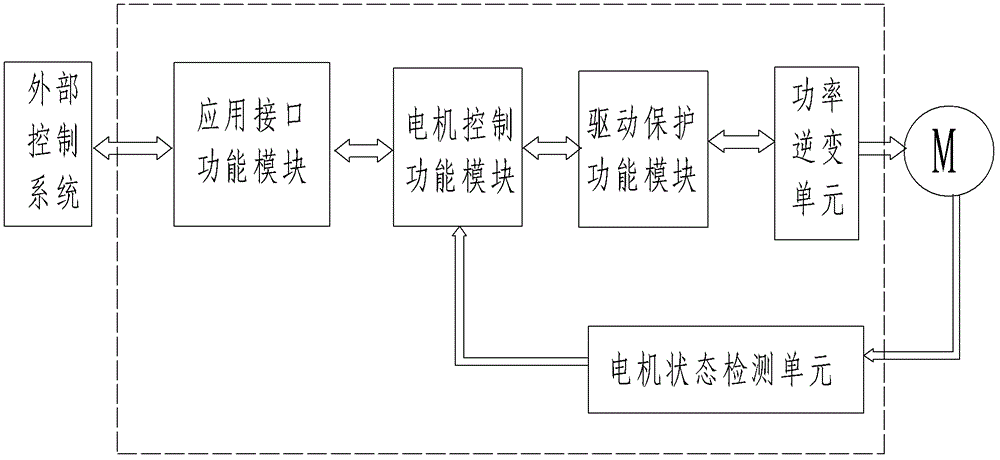

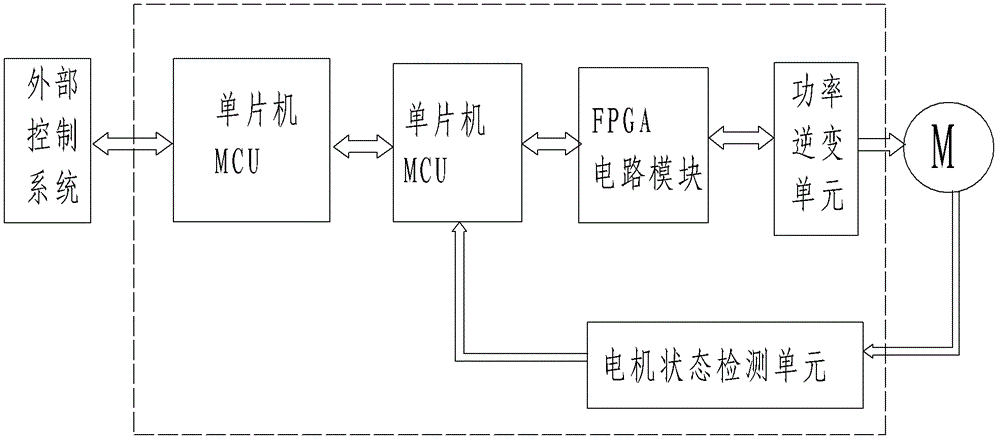

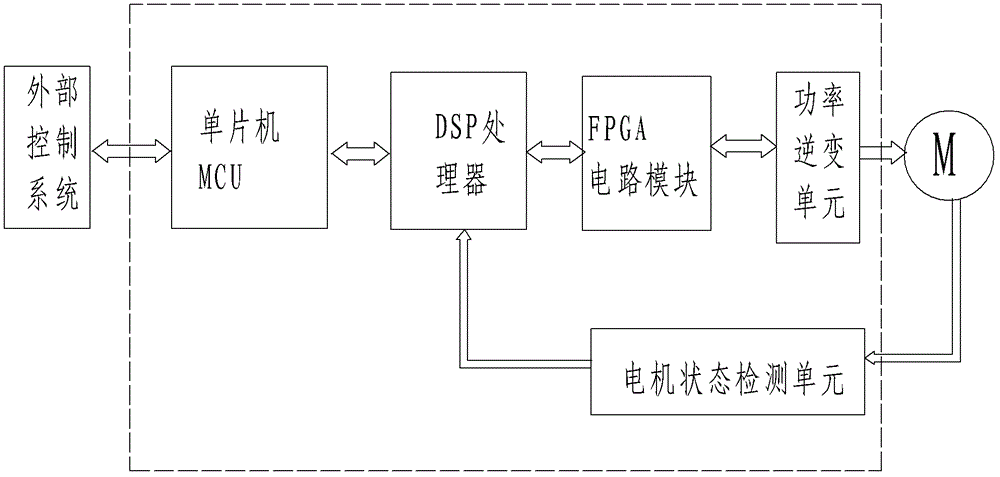

[0023] Such as figure 1 , Figure 5 As shown, a motor controller with a layered multi-core structure, including a power inverter unit that drives the motor, divides the motor controller into three independent systems from the inside to the outside and from bottom to top, which are the drive layer system, The control layer system and the application layer system, wherein: the drive layer system is realized by the drive function protection module, which monitors the operation of the power inverter unit in real time. When the power inverter unit fails, it will quickly and actively protect it; the control layer system is controlled by the motor function modules to complete the motor control algorithm; the application layer system is realized by the application interface function module, facing the user control system, and communicating with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com