Voltage compensation circuit of self-adaptive load cable

A technology of self-adaptive load and voltage compensation, applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve the problem of inability to adaptively generate compensation voltage, and achieve the effect of stable charging voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

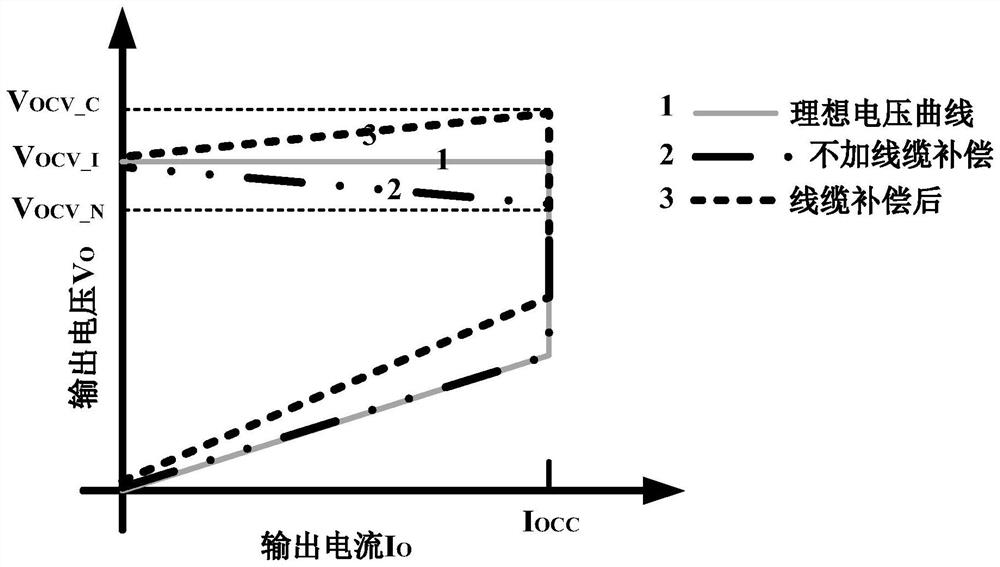

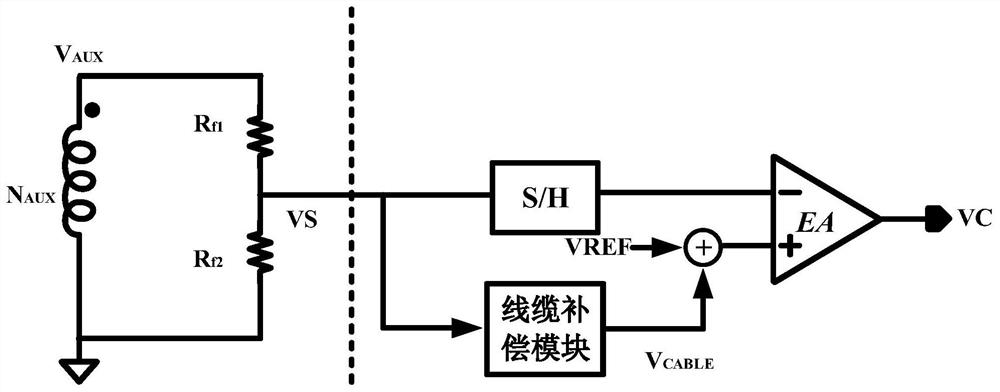

[0024] Such as figure 1 Shown is a comparison chart of the output characteristic curve of a primary-side feedback flyback converter without compensation, the output characteristic curve of the voltage compensation of the present invention, and the ideal output characteristic curve. The primary-side feedback flyback converter controlled by constant voltage output uses the error amplifier EA to amplify the error between the sampling voltage VS of the primary-side feedback flyback converter output voltage and the reference voltage VREF, and then controls the power transistor of the primary-side feedback flyback converter to conduct and off, the output characteristic voltage curve of the primary side feedback flyback converter is the ideal output characteristic voltage curve of curve 1. At this time, there is no load cable, and the output node vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com